An Add-on Current Limiter

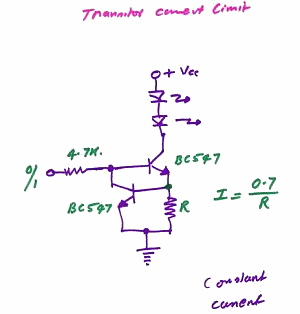

This circuit allows for the establishment of a maximum output current limit from a power supply unit (PSU). It is particularly beneficial when initially powering a project or conducting a soak test. By imposing an upper current limit, protection is afforded to both the power supply and any connected devices. This solution serves as a simple and cost-effective alternative to a current limiting power supply. The basic circuit is depicted in the first schematic. Two diodes stabilize the voltage at the base of the power transistor at approximately 1.4V, resulting in a fixed voltage of about 0.7V across resistor R2. If R2 is valued at 10 ohms, the maximum emitter current is calculated to be around 70mA. Since the collector current closely matches the emitter current, the output terminals cannot provide more than 70mA. Exceeding this limit will cause the output voltage to drop. A BD131 transistor is utilized, but any NPN power transistor with similar or superior specifications can be employed. The choice of a 70mA maximum is arbitrary; altering the value of R2 can adjust the current limit, as indicated by the formula in the schematic. It is important to note that increasing the current will also increase the power dissipation. The second schematic introduces additional features. An LED can be used in place of a voltmeter on the output; if the output voltage decreases, the LED will dim or turn off, indicating excessive load. For unattended operation, such as during a soak test, a buzzer provides an alert if the output voltage drops by 2 volts or more. The layout for the second schematic is flexible; omitting the LED and R3 is possible if the LED feature is not desired, while the alarm feature can be removed by excluding D3, D4, D5, R4, R5, and Q2. A heatsink, made from a folded aluminum strip approximately 2mm thick, 6cm long, and 3cm tall, is recommended. If the maximum current from the limiter circuit is significantly increased, a larger heatsink may be necessary. Support materials for this circuit include a detailed construction guide for the circuit board, a parts list, and a complete circuit description.

The circuit operates on the principle of current limiting through a feedback mechanism involving a power transistor and resistive elements. The diodes used in the circuit ensure that the base voltage of the transistor remains stable, which is crucial for maintaining consistent operation. The choice of R2 directly influences the maximum current output, and the relationship between voltage, current, and resistance follows Ohm's Law. When the load attempts to draw more current than the set limit, the feedback mechanism causes the transistor to reduce the output voltage, thereby protecting the circuit from overcurrent conditions.

In the enhanced schematic, the addition of an LED provides a visual indication of circuit status, offering a straightforward means for users to monitor the output without needing additional equipment. The buzzer feature further enhances usability, especially in scenarios where the circuit may be left unattended. This alert system is critical for preventing damage to components and ensuring safety during long-term tests.

The design's flexibility allows for customization based on user requirements. Components can be omitted or included based on the specific application, thereby tailoring the circuit for various use cases. The recommended heatsink dimensions are designed to dissipate heat effectively, ensuring the transistor operates within safe limits. If the current limit is adjusted upwards, careful consideration of thermal management becomes essential to avoid overheating and potential failure of the transistor.

Overall, the circuit provides a robust solution for current limiting, with features that enhance usability and safety, making it suitable for a variety of electronic projects.This circuit allows you to set a limit on the maximum output current available from your PSU. It`s very useful when you power-up a project for the first time - or carry out a soak-test. By setting an upper limit on the current available from your PSU - you can protect both your power supply - and any device connected to it. It offers a simple and cheap alternative to the Current Limiting Power Supply The basic circuit is shown in the first schematic. The two diodes fix the voltage on the base of the Power Transistor at about 1v4. This means that the voltage across R2 is fixed at about 0v7. If R2 is 10 ohms, then the maximum emitter current is (0v7 G ½10) about 70mA. Since the collector current is always more or less equal to the emitter current - you cannot draw more than 70mA from the output terminals.

If you try to do so - the output voltage will fall. I used a BD131 because that was what I had available. However, any NPN Power Transistor with a similar - or better - spec should work fine. I had no special reason for chosing a 70mA maximum. If you want to set a different current limit - change the value of R2. The formula is in the diagram. Always remember that if you increase the current - you`ll also increase the watts. The second schematic has a couple of added features. If you don`t want to use a voltmeter on the output - use an LED instead. If the output voltage falls - the LED will dim or extinguish completely. This is enough to let you know that the load on the output is excessive. Where the Current Limiter is to be left unattended for any length of time - say during a soak-test - the Buzzer is useful. Should a problem develope - and the output voltage fall by 2-volts or more - the circuit will sound the alarm.

The layout provided is for the second schematic - but it`s flexible. If you don`t want the LED feature - just leave out the LED and R3. If you don`t want the alarm feature - leave out D3, D4, D5, R4, R5 & Q2. The heatsink is a folded strip of aluminium about 2mm thick, 6cm long and 3cm tall. If you increase significantly the maximum current available from the limiter circuit - you`ll probably need to increase the size of the heatsink as well. The Support Material for this circuit includes a detailed guide to the construction of the circuit-board, a parts list, a complete circuit description and more

🔗 External reference

The circuit operates on the principle of current limiting through a feedback mechanism involving a power transistor and resistive elements. The diodes used in the circuit ensure that the base voltage of the transistor remains stable, which is crucial for maintaining consistent operation. The choice of R2 directly influences the maximum current output, and the relationship between voltage, current, and resistance follows Ohm's Law. When the load attempts to draw more current than the set limit, the feedback mechanism causes the transistor to reduce the output voltage, thereby protecting the circuit from overcurrent conditions.

In the enhanced schematic, the addition of an LED provides a visual indication of circuit status, offering a straightforward means for users to monitor the output without needing additional equipment. The buzzer feature further enhances usability, especially in scenarios where the circuit may be left unattended. This alert system is critical for preventing damage to components and ensuring safety during long-term tests.

The design's flexibility allows for customization based on user requirements. Components can be omitted or included based on the specific application, thereby tailoring the circuit for various use cases. The recommended heatsink dimensions are designed to dissipate heat effectively, ensuring the transistor operates within safe limits. If the current limit is adjusted upwards, careful consideration of thermal management becomes essential to avoid overheating and potential failure of the transistor.

Overall, the circuit provides a robust solution for current limiting, with features that enhance usability and safety, making it suitable for a variety of electronic projects.This circuit allows you to set a limit on the maximum output current available from your PSU. It`s very useful when you power-up a project for the first time - or carry out a soak-test. By setting an upper limit on the current available from your PSU - you can protect both your power supply - and any device connected to it. It offers a simple and cheap alternative to the Current Limiting Power Supply The basic circuit is shown in the first schematic. The two diodes fix the voltage on the base of the Power Transistor at about 1v4. This means that the voltage across R2 is fixed at about 0v7. If R2 is 10 ohms, then the maximum emitter current is (0v7 G ½10) about 70mA. Since the collector current is always more or less equal to the emitter current - you cannot draw more than 70mA from the output terminals.

If you try to do so - the output voltage will fall. I used a BD131 because that was what I had available. However, any NPN Power Transistor with a similar - or better - spec should work fine. I had no special reason for chosing a 70mA maximum. If you want to set a different current limit - change the value of R2. The formula is in the diagram. Always remember that if you increase the current - you`ll also increase the watts. The second schematic has a couple of added features. If you don`t want to use a voltmeter on the output - use an LED instead. If the output voltage falls - the LED will dim or extinguish completely. This is enough to let you know that the load on the output is excessive. Where the Current Limiter is to be left unattended for any length of time - say during a soak-test - the Buzzer is useful. Should a problem develope - and the output voltage fall by 2-volts or more - the circuit will sound the alarm.

The layout provided is for the second schematic - but it`s flexible. If you don`t want the LED feature - just leave out the LED and R3. If you don`t want the alarm feature - leave out D3, D4, D5, R4, R5 & Q2. The heatsink is a folded strip of aluminium about 2mm thick, 6cm long and 3cm tall. If you increase significantly the maximum current available from the limiter circuit - you`ll probably need to increase the size of the heatsink as well. The Support Material for this circuit includes a detailed guide to the construction of the circuit-board, a parts list, a complete circuit description and more

🔗 External reference