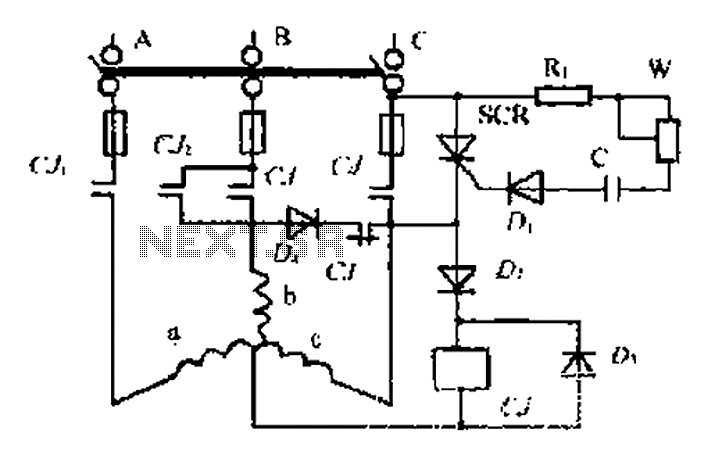

An induction motor dynamic braking control circuit

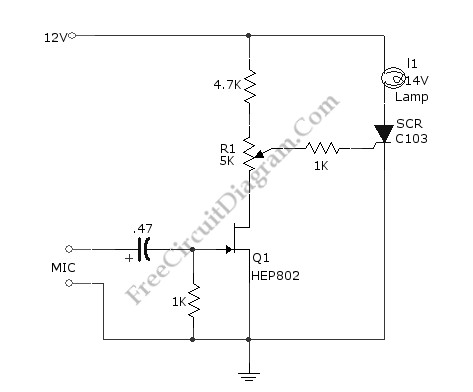

AC contactor controls suction units, with the motor activated simultaneously. A pair of contacts (CJ1) short-circuits the thyristor (SCR), turning it off. The contactor (C) is influenced by the diode's DC voltage. In the positive half-wave power cycle, the SCR's control electrode receives trigger current through resistors (R, W) and components (C, D1), allowing conduction. The motor's b and c-phase windings are powered through the SCR, while contacts CJ2 provide half-rectified current. The SCR also supplies bi-directional wave current to maintain suction units. At the end of the positive half-wave, the b and c-phase windings induce a back electromotive force (EMF), and the normally closed contact (D4) serves as a freewheeling path until the next positive half-cycle. The SCR is reactivated, and the b and c-phase windings do not experience a current fork. The cycle continues with charge storage, while the SCR trigger current is reduced to facilitate small dynamic braking. The power remains engaged, with a minimal chance of SCR exclusion.

The circuit utilizes an AC contactor to manage the operation of suction units, integrating a thyristor (SCR) for effective control of the motor's operation. The contactor's primary function is to switch the motor on and off, ensuring that the suction units operate efficiently. When the motor is activated, the contacts CJ1 create a short circuit across the SCR, effectively turning it off to prevent unintended current flow.

During the positive half of the AC waveform, the SCR is triggered through a series of components, including resistors and diodes, which provide the necessary gate current for conduction. The motor receives power through its b and c-phase windings, with contact CJ2 supplying a half-rectified current that supports the motor's operation. The SCR also plays a vital role in delivering bi-directional wave current, which is essential for maintaining the suction units' functionality.

As the positive half-cycle concludes, the induced back EMF in the b and c-phase windings activates the normally closed contact D4, allowing for a freewheeling path that ensures continuity of operation until the next half-cycle. This design prevents abrupt changes in current, contributing to the stability of the system.

The SCR is re-triggered at the onset of the next positive half-cycle, maintaining the current flow through the windings without interruption. The circuit is designed to manage energy efficiently, with charge storage mechanisms in place that allow for dynamic braking when necessary. This braking system minimizes mechanical wear and enhances the longevity of the motor.

Overall, the design emphasizes reliable operation and energy efficiency, utilizing the principles of AC control and SCR technology to achieve effective motor management in the context of suction units. The circuit is structured to ensure safe operation, with considerations for both dynamic braking and the prevention of undesired SCR exclusion under normal operating conditions.AC contactor Cli suction units, motor was switched on at the same time, CJ1 pair of contacts to the thyristor SCR shorted SCR it off. Contactor C interesting by the diode DC vo ltage and suction units, make energy system moving like love. In the positive half-wave power, SCR control electrode through R, W. C, Dl get trigger current conduction through, motor b, c-phase winding through the SCR, CJ2 contacts is to give a half rectified current, C is also provided by SCR BI wave current to maintain suction units. When the end of the positive half-wave current, b. c-phase winding fork induced electric boat, the D4. cl normally closed contact freewheeling. Sentenced next positive half cycle. SCR is turned on again. b, c-phase winding half do not have to fork crossing the current, past through the next cycle, c charge storage charges, SCR trigger current of less than bottles instead guide ila, complete small dynamic braking.

CJ, the power is not released, the SCR again through the small possibility of exclusion.

The circuit utilizes an AC contactor to manage the operation of suction units, integrating a thyristor (SCR) for effective control of the motor's operation. The contactor's primary function is to switch the motor on and off, ensuring that the suction units operate efficiently. When the motor is activated, the contacts CJ1 create a short circuit across the SCR, effectively turning it off to prevent unintended current flow.

During the positive half of the AC waveform, the SCR is triggered through a series of components, including resistors and diodes, which provide the necessary gate current for conduction. The motor receives power through its b and c-phase windings, with contact CJ2 supplying a half-rectified current that supports the motor's operation. The SCR also plays a vital role in delivering bi-directional wave current, which is essential for maintaining the suction units' functionality.

As the positive half-cycle concludes, the induced back EMF in the b and c-phase windings activates the normally closed contact D4, allowing for a freewheeling path that ensures continuity of operation until the next half-cycle. This design prevents abrupt changes in current, contributing to the stability of the system.

The SCR is re-triggered at the onset of the next positive half-cycle, maintaining the current flow through the windings without interruption. The circuit is designed to manage energy efficiently, with charge storage mechanisms in place that allow for dynamic braking when necessary. This braking system minimizes mechanical wear and enhances the longevity of the motor.

Overall, the design emphasizes reliable operation and energy efficiency, utilizing the principles of AC control and SCR technology to achieve effective motor management in the context of suction units. The circuit is structured to ensure safe operation, with considerations for both dynamic braking and the prevention of undesired SCR exclusion under normal operating conditions.AC contactor Cli suction units, motor was switched on at the same time, CJ1 pair of contacts to the thyristor SCR shorted SCR it off. Contactor C interesting by the diode DC vo ltage and suction units, make energy system moving like love. In the positive half-wave power, SCR control electrode through R, W. C, Dl get trigger current conduction through, motor b, c-phase winding through the SCR, CJ2 contacts is to give a half rectified current, C is also provided by SCR BI wave current to maintain suction units. When the end of the positive half-wave current, b. c-phase winding fork induced electric boat, the D4. cl normally closed contact freewheeling. Sentenced next positive half cycle. SCR is turned on again. b, c-phase winding half do not have to fork crossing the current, past through the next cycle, c charge storage charges, SCR trigger current of less than bottles instead guide ila, complete small dynamic braking.

CJ, the power is not released, the SCR again through the small possibility of exclusion.

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713