Another kind of relay driver board used to utilize your old PC

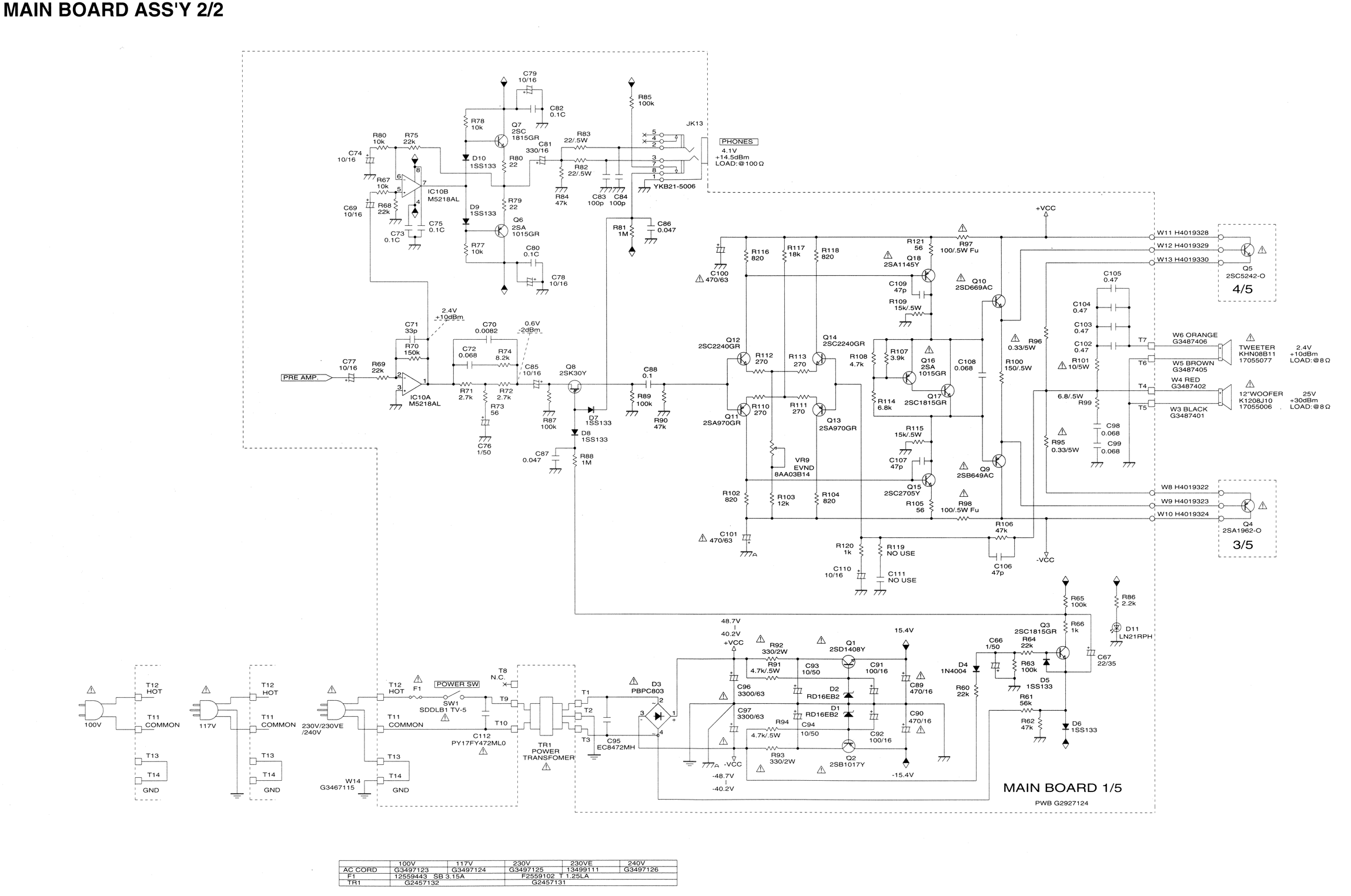

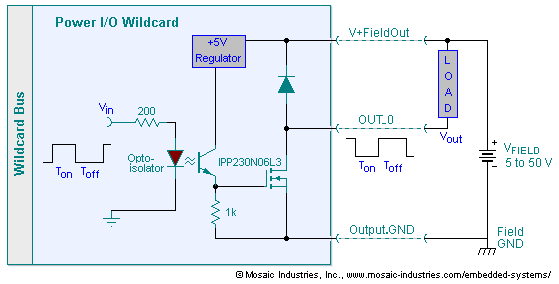

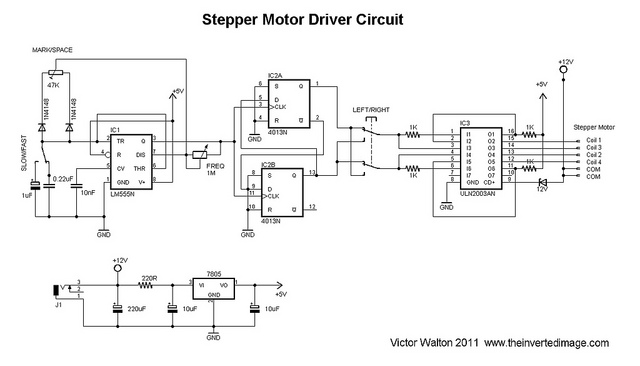

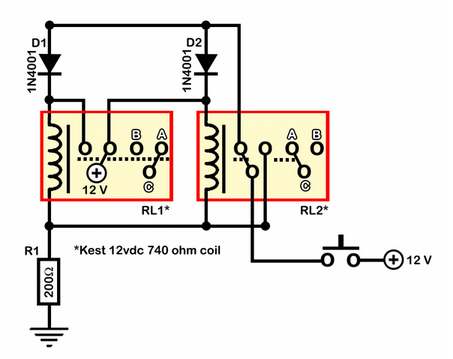

This article discusses the utilization of old PCs as simple controllers. Many obsolete systems, such as the 8088, 8086, 80286, 80386, and 80486, are no longer capable of running modern software, yet they can still function effectively. Often, individuals abandon these systems in favor of newer models, like the Pentium type. However, these old PCs can be repurposed for various experiments. This guide encourages the creation of a simple controller using eight relays for multiple applications, such as turning lights on and off, controlling home stereo systems, managing appliances, creating timers, or setting up home alarms. The design employs an 8-bit LPT printer parallel data port (DP) to activate the relays, while the additional 4-bit port (PC) is not utilized in this design, as the 8 bits are deemed sufficient and compatible with the 8255 PPI port for interfacing. Each of the eight channels operates on the same principle. To safeguard the LPT port from damage, optocouplers are used to isolate the PC side (+5V) from the relay circuit (+24V). The relay voltage type can be adjusted to +12V or +6V if necessary. The PC914 optocoupler can be substituted with other types from the 4N series. A common driver configuration using high-power transistors (Q1 to Q8) drives the relays, while diodes (D1 to D8) protect the transistors from transient currents when the relays are off. Resistor values are selected to ensure full saturation of the transistors when activated. Alternatively, IC drivers like ULN2002 to ULN2004 can be employed, requiring two ICs to achieve full functionality. It is crucial to select relays capable of handling high voltage and current for AC line applications. Extra caution is necessary to maintain safe distances between high-voltage and low-voltage lines on the PCB. A terminal strip is used for connecting high-voltage power wires. A PCB has been designed for the relay driver, which, while not compact, operates effectively. The data byte utilized is from the DP port, and pins 18 to 25 are connected to ground. The PCB includes a voltage regulator (+24V), which can be easily modified by changing the regulator. A DB-25 connector is used for data connections, facilitating easy interfacing with the LPT printer parallel port or other ports like the 8255 PPI. For those without Protel software, a PDF schematic layout is available. Components include capacitors (C1 and C2), diodes (D1 to D12), LEDs (Led1 to Led9), a voltage regulator (IC1), transistors (Q1 to Q8), optocouplers (OP1 to OP8), relays (RL1 to RL8), connectors (CON1 and optional CON2), terminal strips (OUT-1 to OUT-8), a transformer, and optional components such as a power switch and heatsink. Various ready-to-use software options exist, or custom software can be developed for specific purposes. The primary objective is to ensure the successful operation of the new card.

To implement this project, the following steps are recommended:

1. **Component Selection**: Choose high-quality components that meet the required specifications. For the relays, ensure they can handle the necessary voltage and current ratings, especially if controlling AC devices.

2. **PCB Design**: Utilize PCB design software to create a layout that accommodates all components while maintaining adequate spacing between high-voltage and low-voltage sections. Ensure that the ground connections are solid and that the layout minimizes noise.

3. **Optocoupler Configuration**: Use the optocouplers to isolate the control signals from the high-voltage relay circuits. This is critical for protecting the LPT port and ensuring reliable operation of the relays.

4. **Testing and Validation**: After assembling the components on the PCB, conduct thorough testing to validate the functionality of each relay and the overall system. Use multimeters and oscilloscopes to check for proper voltage levels and signal integrity.

5. **Software Development**: If custom software is needed, develop it to interface with the LPT port, ensuring it can send the correct signals to activate the relays as intended. Utilize available software libraries for easier integration.

6. **Safety Precautions**: When working with high-voltage circuits, always observe safety precautions. Use insulated tools, and ensure that the power supply is disconnected when making adjustments to the circuit.

7. **Documentation**: Maintain detailed documentation of the design, component specifications, and software used. This will facilitate troubleshooting and future modifications.

By following these guidelines, the old PC can be effectively transformed into a versatile controller capable of managing various devices and applications.This article means to utilize your old PC to be come a simple controller. Many old PC like 8088 type, 8086, 80286, 80386, or even 80486 already become an obsolete systems, since they can not run many new program now a days. In fact, this system still also can be run well. Many people has let their own not used, since they have a new one (pentium t ype). Thus what for this old system now For people like us, we can use this old PC to make any experiment. Here I will stimulate you to take advantage, make a simple controller using 8 relays to make a variety uses like; turning on/off lights, turn your home stereo set, on/off you home appliance, make a timer device, make a home device alarm, etc. All application depends on your imagination. This board using 8-bits of LPT printer parallel data port (DP) to activate the relays. LPT printer parallel port also have 4-bits additional port (PC) which can be utilized too. But this is not implemented in this design, because in my opinion, 8-bits are more than enough, and beside that this size (1 byte) fit each of 8255 PPI port if we want to interface it too.

The basic is the same for all the eight channels. To protect the LPT port from damage, I use optocoupler to isolated the PC side (+5V) and relay circuit (+24V). You can change the relay voltage type to +12V or even +6V if you can find one. This type of optocoupler, PC914 can be replaced with another type like 4N series (4N22 ~ 4N28, 4N35, 4N47 ~ 4N49, etc.

). Using a common driver combination, transistor Q1 ~ Q8 (hi-power) to drive the relays. D1 ~ D8 use to protect the transistor from any transient current when the relay is in the off state. The resistor values are chosen to make transistors get full enough saturated when it is on. This common driver also can be change using IC driver like: ULN2002 ~ ULN2004 types. Each package contain 6-bits line drivers. So you need 2 of this IC, but one does not maximize. If you use PC port, than this IC can be utilized. A good alternative. Note that, for the relays, it must be stand the high voltage and current (big power) if you want to use it to drive any equiptment from the AC line. Find a good ones with a high rating output. Careful about the hi-voltage line on the PCB. Extra care must be taken in order to prevent the two different voltage lines not laying in the close distance.

I used a terminal strip to connect this hi-voltage power wire. Here I already designed the PCB for this relays driver. Not very compact, but already run well. Only data byte were used (DP port). Note that, pin 18 through 25 all together connected to ground. This PCB also included with power supply voltage regulator (+24V). Its very easy to change it to any other voltage by changed the voltage regulator only. For the data connection, as usual I used a DB-25 connector, to be easy to connected to LPT printer parallel port or for future using, when we want to connect it to any other port (like 8255-PPI port). For any reader who doesn`t have protel software, you can also printout this pdf schematic layout (90.

414 Bytes). C1 = 2200 uF/50V (elco). 1 pcs C2 = 1000 uF/25V (elco). 1 pcs D1 ~ D12 = 1N4007. 12 pcs Led1 ~ Led9 = Red Led (3 mm). 9 pcs IC1 = 7824 (voltage regulator). 1 pcs Q1 ~ Q8 = C1061 (transistor). 8 pcs OP1 ~ OP8 = PC914 (optocoupler). 8 pcs RL1 ~ RL8 = 24V relay PCB type (hi-power output, 5A/220V-AC). 8 pcs CON1 = DB-25 socket (female, PCB type, LPT connector). 1 pcs Optional CON2 = power connector. 1 pcs OUT-1 ~ OUT-8 = 2-pairs of terminal strip. 8 pcs Transformer = 15V with CT/1A or 30V-AC/1A. 1 pcs Optional on/off switch for power supply. 1 pcs Optional LPT parallel port cable (3 m). 1 pcs Optional little heatsink for voltage regulator. 1 pcs There are many `ready to use software`. Besides that you can write your own software as your purpose. But our goal now is to run our new card well. Here is a good free software I found on the electronic CD r 🔗 External reference

To implement this project, the following steps are recommended:

1. **Component Selection**: Choose high-quality components that meet the required specifications. For the relays, ensure they can handle the necessary voltage and current ratings, especially if controlling AC devices.

2. **PCB Design**: Utilize PCB design software to create a layout that accommodates all components while maintaining adequate spacing between high-voltage and low-voltage sections. Ensure that the ground connections are solid and that the layout minimizes noise.

3. **Optocoupler Configuration**: Use the optocouplers to isolate the control signals from the high-voltage relay circuits. This is critical for protecting the LPT port and ensuring reliable operation of the relays.

4. **Testing and Validation**: After assembling the components on the PCB, conduct thorough testing to validate the functionality of each relay and the overall system. Use multimeters and oscilloscopes to check for proper voltage levels and signal integrity.

5. **Software Development**: If custom software is needed, develop it to interface with the LPT port, ensuring it can send the correct signals to activate the relays as intended. Utilize available software libraries for easier integration.

6. **Safety Precautions**: When working with high-voltage circuits, always observe safety precautions. Use insulated tools, and ensure that the power supply is disconnected when making adjustments to the circuit.

7. **Documentation**: Maintain detailed documentation of the design, component specifications, and software used. This will facilitate troubleshooting and future modifications.

By following these guidelines, the old PC can be effectively transformed into a versatile controller capable of managing various devices and applications.This article means to utilize your old PC to be come a simple controller. Many old PC like 8088 type, 8086, 80286, 80386, or even 80486 already become an obsolete systems, since they can not run many new program now a days. In fact, this system still also can be run well. Many people has let their own not used, since they have a new one (pentium t ype). Thus what for this old system now For people like us, we can use this old PC to make any experiment. Here I will stimulate you to take advantage, make a simple controller using 8 relays to make a variety uses like; turning on/off lights, turn your home stereo set, on/off you home appliance, make a timer device, make a home device alarm, etc. All application depends on your imagination. This board using 8-bits of LPT printer parallel data port (DP) to activate the relays. LPT printer parallel port also have 4-bits additional port (PC) which can be utilized too. But this is not implemented in this design, because in my opinion, 8-bits are more than enough, and beside that this size (1 byte) fit each of 8255 PPI port if we want to interface it too.

The basic is the same for all the eight channels. To protect the LPT port from damage, I use optocoupler to isolated the PC side (+5V) and relay circuit (+24V). You can change the relay voltage type to +12V or even +6V if you can find one. This type of optocoupler, PC914 can be replaced with another type like 4N series (4N22 ~ 4N28, 4N35, 4N47 ~ 4N49, etc.

). Using a common driver combination, transistor Q1 ~ Q8 (hi-power) to drive the relays. D1 ~ D8 use to protect the transistor from any transient current when the relay is in the off state. The resistor values are chosen to make transistors get full enough saturated when it is on. This common driver also can be change using IC driver like: ULN2002 ~ ULN2004 types. Each package contain 6-bits line drivers. So you need 2 of this IC, but one does not maximize. If you use PC port, than this IC can be utilized. A good alternative. Note that, for the relays, it must be stand the high voltage and current (big power) if you want to use it to drive any equiptment from the AC line. Find a good ones with a high rating output. Careful about the hi-voltage line on the PCB. Extra care must be taken in order to prevent the two different voltage lines not laying in the close distance.

I used a terminal strip to connect this hi-voltage power wire. Here I already designed the PCB for this relays driver. Not very compact, but already run well. Only data byte were used (DP port). Note that, pin 18 through 25 all together connected to ground. This PCB also included with power supply voltage regulator (+24V). Its very easy to change it to any other voltage by changed the voltage regulator only. For the data connection, as usual I used a DB-25 connector, to be easy to connected to LPT printer parallel port or for future using, when we want to connect it to any other port (like 8255-PPI port). For any reader who doesn`t have protel software, you can also printout this pdf schematic layout (90.

414 Bytes). C1 = 2200 uF/50V (elco). 1 pcs C2 = 1000 uF/25V (elco). 1 pcs D1 ~ D12 = 1N4007. 12 pcs Led1 ~ Led9 = Red Led (3 mm). 9 pcs IC1 = 7824 (voltage regulator). 1 pcs Q1 ~ Q8 = C1061 (transistor). 8 pcs OP1 ~ OP8 = PC914 (optocoupler). 8 pcs RL1 ~ RL8 = 24V relay PCB type (hi-power output, 5A/220V-AC). 8 pcs CON1 = DB-25 socket (female, PCB type, LPT connector). 1 pcs Optional CON2 = power connector. 1 pcs OUT-1 ~ OUT-8 = 2-pairs of terminal strip. 8 pcs Transformer = 15V with CT/1A or 30V-AC/1A. 1 pcs Optional on/off switch for power supply. 1 pcs Optional LPT parallel port cable (3 m). 1 pcs Optional little heatsink for voltage regulator. 1 pcs There are many `ready to use software`. Besides that you can write your own software as your purpose. But our goal now is to run our new card well. Here is a good free software I found on the electronic CD r 🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713