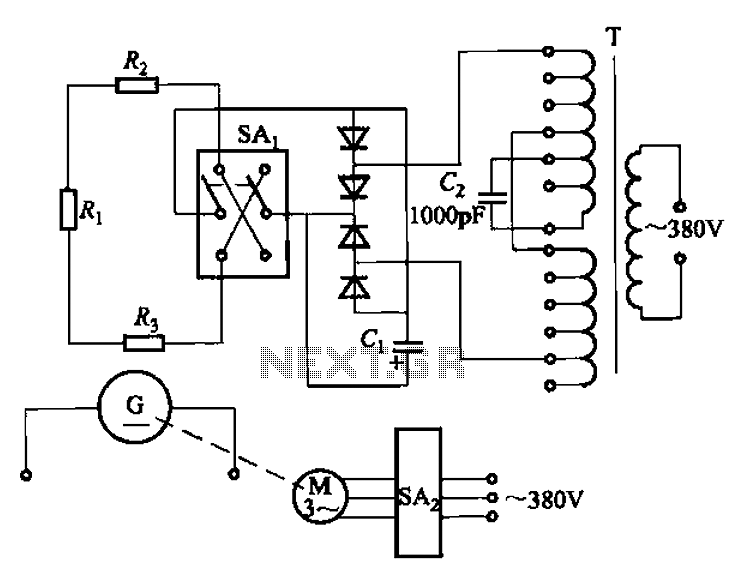

AR-300 DC arc welding machine circuit

The AR-300 DC arc welding machine circuit includes the AX, AX1, AX3, and AR series. The structure of these machines is fundamentally similar, consisting of a three-integral unit converter, a phase asynchronous motor, and a DC arc welding generator in a coaxial configuration. The AX series features current regulation with both coarse and fine adjustments. The coarse adjustment has three fixed positions, which are located in a concave groove on the lid and are adjusted by moving the brush holder. Moving the brush holder along the steering motor results in a decrease in operating current; conversely, moving it in the opposite direction increases the current. The fine adjustment is made by altering the shunt winding resistance using a hand wheel. The AX1 series also provides coarse and fine current regulation; the coarse adjustment modifies the series excitation winding turns on the line panel, while the fine adjustment is achieved by changing the resistance of the Reed winding transformer group using a hand wheel. The AX3 series features both coarse and fine current regulation as well. The coarse adjustment is implemented through a single-throw switch with two settings: large and small. Fine-tuning is accomplished by moving the brush with a hand wheel. Polarity changes can be made via a double-throw switch, which allows for flipping down and retaining the previous setting.

The AR-300 DC arc welding machine is designed for efficient and precise welding applications. The coaxial configuration of the motor and generator minimizes space requirements while ensuring optimal performance. The current regulation system is a critical feature, allowing the operator to adjust the welding current to suit different materials and thicknesses. The coarse adjustment mechanism, with its fixed stop positions, provides a reliable means of quickly setting the current to a desired range, while the fine adjustment allows for more precise control. This dual adjustment capability is particularly beneficial for applications requiring varying welding parameters.

In the AX series, the use of a hand wheel to adjust the shunt winding resistance provides a tactile and user-friendly interface, enabling quick changes during operation. The AX1 series builds on this by integrating a more complex system of resistance changes, enhancing the flexibility of current settings. The AX3 series introduces a simplified approach to coarse adjustments with a single-throw switch, enhancing usability for operators who may need to switch between settings rapidly.

The polarity change mechanism in the AX3 series is noteworthy, allowing for quick adjustments that can affect the weld characteristics significantly. This feature is essential for operators who frequently switch between different welding tasks, as it enables them to maintain consistency and quality in their work. Overall, the AR-300 series of DC arc welding machines presents a robust solution for various welding needs, combining user-friendly interfaces with advanced engineering to deliver reliable performance.AR-300 DC arc welding machine circuit Rotary DC arc welding machine has AX, AX1, AX3 and AR series. Its structure is basically the same, are made of a three integral unit conve rter phase asynchronous motor and a DC arc welding generator coaxial configuration. AX series DC arc welding machine current regulation has two coarse and fine adjustment. Coarse There are three stop positions, fixed in the lid concave groove, which is moving through the brush holder to achieve. Move along the steering motor brush holder, the operating current is reduced; conversely, the operating current increases.

Fine tuning is to change the shunt winding resistance varistor by hand wheel to achieve. AX1 series DC arc welding machine has a current regulating coarse and fine two kinds. Coarse is by changing the line panel series excitation winding turns to achieve. Fine-tuning is changed by the handwheel and realized Reed winding transformer groups resistance. AX3 series DC arc welding machine has a current regulating coarse and fine two kinds. Coarse There are two block from large and small tokens of single-throw switch to achieve. Fine-tuning by hand wheel moving brush to achieve. Polarity change can flip the down, smooth remember number to achieve double-throw switch.

The AR-300 DC arc welding machine is designed for efficient and precise welding applications. The coaxial configuration of the motor and generator minimizes space requirements while ensuring optimal performance. The current regulation system is a critical feature, allowing the operator to adjust the welding current to suit different materials and thicknesses. The coarse adjustment mechanism, with its fixed stop positions, provides a reliable means of quickly setting the current to a desired range, while the fine adjustment allows for more precise control. This dual adjustment capability is particularly beneficial for applications requiring varying welding parameters.

In the AX series, the use of a hand wheel to adjust the shunt winding resistance provides a tactile and user-friendly interface, enabling quick changes during operation. The AX1 series builds on this by integrating a more complex system of resistance changes, enhancing the flexibility of current settings. The AX3 series introduces a simplified approach to coarse adjustments with a single-throw switch, enhancing usability for operators who may need to switch between settings rapidly.

The polarity change mechanism in the AX3 series is noteworthy, allowing for quick adjustments that can affect the weld characteristics significantly. This feature is essential for operators who frequently switch between different welding tasks, as it enables them to maintain consistency and quality in their work. Overall, the AR-300 series of DC arc welding machines presents a robust solution for various welding needs, combining user-friendly interfaces with advanced engineering to deliver reliable performance.AR-300 DC arc welding machine circuit Rotary DC arc welding machine has AX, AX1, AX3 and AR series. Its structure is basically the same, are made of a three integral unit conve rter phase asynchronous motor and a DC arc welding generator coaxial configuration. AX series DC arc welding machine current regulation has two coarse and fine adjustment. Coarse There are three stop positions, fixed in the lid concave groove, which is moving through the brush holder to achieve. Move along the steering motor brush holder, the operating current is reduced; conversely, the operating current increases.

Fine tuning is to change the shunt winding resistance varistor by hand wheel to achieve. AX1 series DC arc welding machine has a current regulating coarse and fine two kinds. Coarse is by changing the line panel series excitation winding turns to achieve. Fine-tuning is changed by the handwheel and realized Reed winding transformer groups resistance. AX3 series DC arc welding machine has a current regulating coarse and fine two kinds. Coarse There are two block from large and small tokens of single-throw switch to achieve. Fine-tuning by hand wheel moving brush to achieve. Polarity change can flip the down, smooth remember number to achieve double-throw switch.