Arduino 7 segment Displays Digital Clock With Charlieplexing LEDs

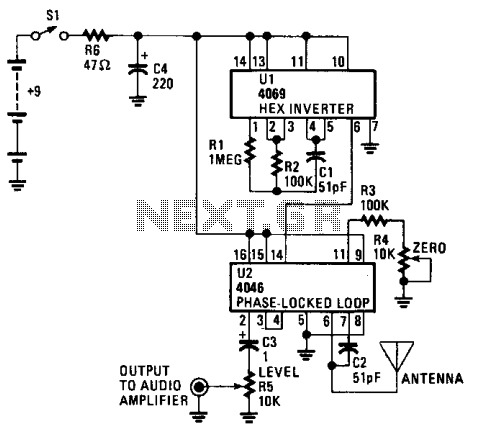

This is the second instructable focused on creating a digital watch as a learning experience. An Atmega644 chip from a Sanguino was available, which would have sufficed, but the intention was to burn an Arduino bootloader and test its functionality. An Atmega168 was ultimately used for the project. Four seven-segment displays were employed to present the time in a 24-hour format, experimenting with both common anode and common cathode configurations. Additionally, various chips were tested, including the 74LS47, 74HC154, 74HC595, 4511, and 74HC139. The final working combination was a common cathode setup using the 4511 and 74HC139. A DS1307 RTC chip was integrated to provide accurate timekeeping to the Arduino, as the millis() function was found to be inaccurate. The RTC not only streamlined the coding process but also maintained time during power outages using a 3V battery. Although a circuit was designed in Eagle, proficiency in the software was lacking, preventing the creation of a printed circuit board (PCB). An Express PCB file was generated, which can be utilized to create a PCB from copper clad or through professional manufacturing. In the Express PCB file, jumpers (JMP) were used in certain locations, indicating the need for wires to connect two pads, as a single-sided PCB was utilized. It is crucial to confirm wire connections based on the circuit diagram. Additionally, jumpers were placed at digital pins 0 and 1; it is essential to disconnect the LEDs from these pins during program uploading, as they are RX and TX pins. Failure to do so may affect the voltage and hinder the upload process, a lesson learned through experience.

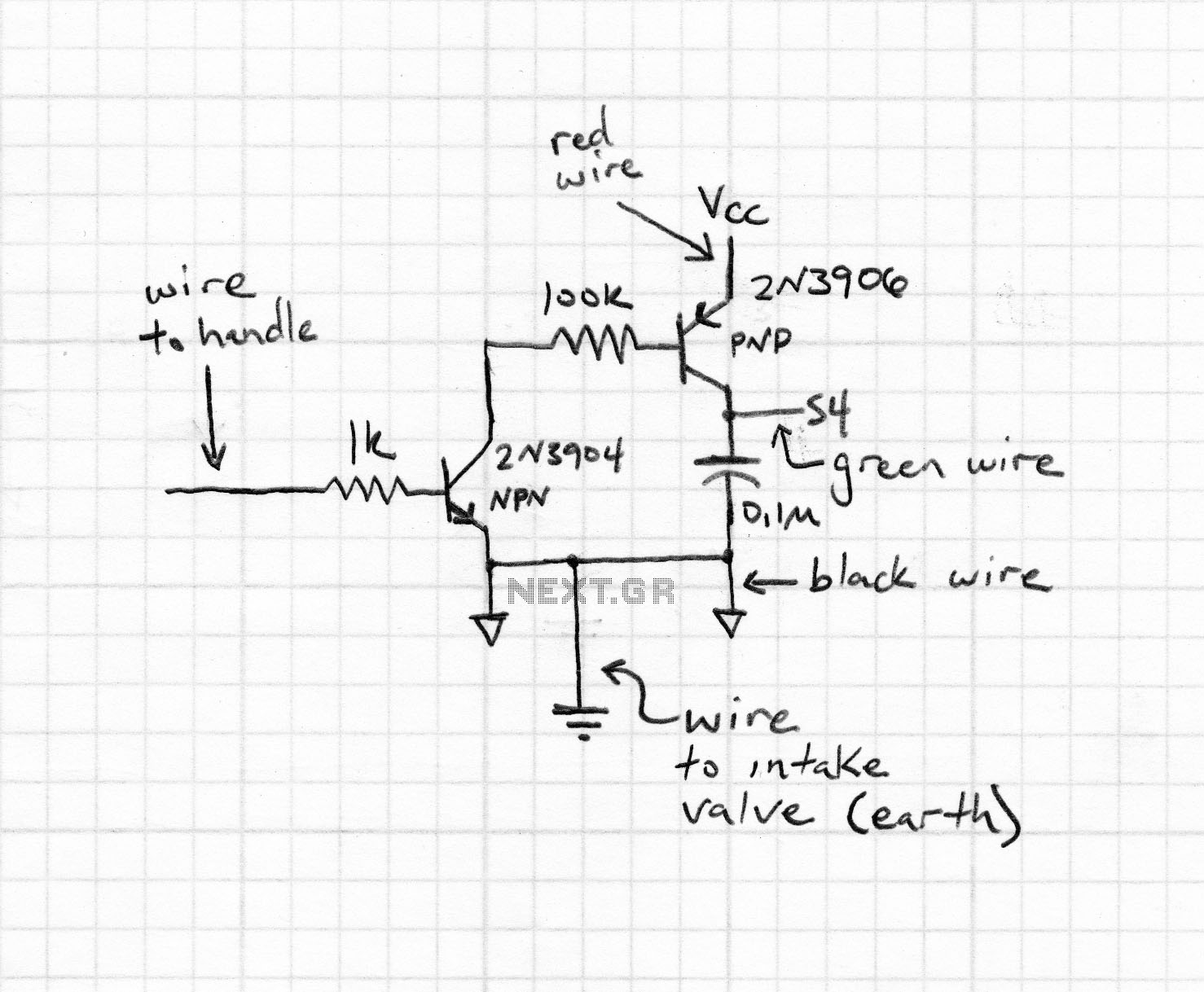

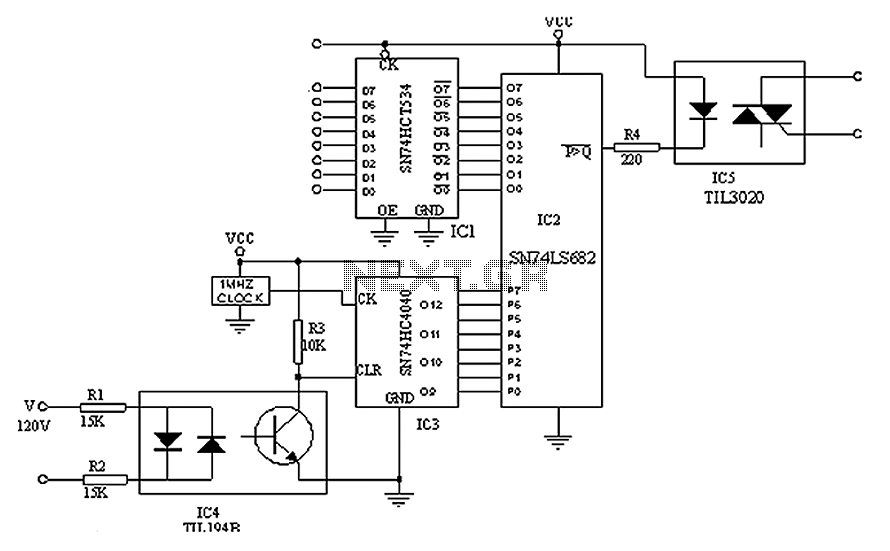

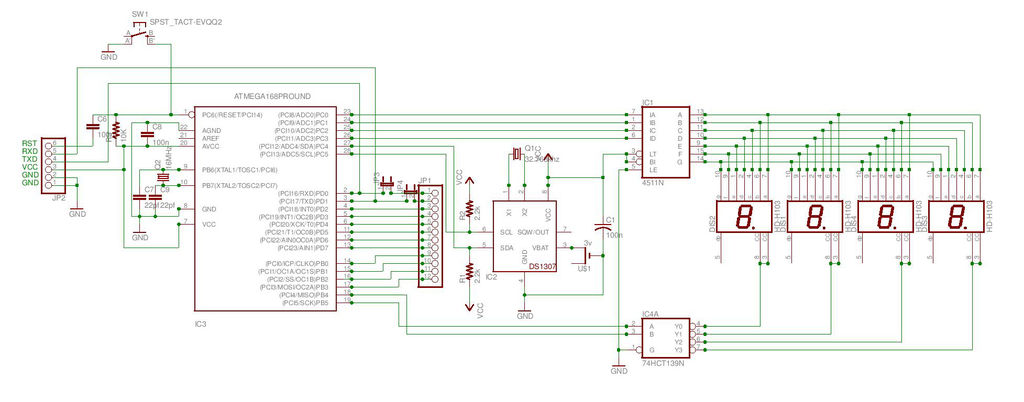

The digital watch circuit utilizes an Atmega168 microcontroller to drive four seven-segment displays configured in a common cathode arrangement, interfacing with the 4511 BCD to 7-segment latch/decoder/driver and the 74HC139 dual 2-to-4 line decoder/demultiplexer. The DS1307 real-time clock (RTC) module communicates with the Atmega168 via I2C, ensuring accurate timekeeping and the ability to retain time settings during power loss through a backup battery. The circuit design incorporates pull-up resistors on the I2C lines to ensure reliable communication.

The schematic includes connections for the seven-segment displays, with appropriate current-limiting resistors to prevent excessive current draw. The use of jumpers in the Express PCB file is specified to accommodate the single-sided design, allowing for manual wire connections where necessary. The design emphasizes the importance of disconnecting the LEDs from the RX and TX pins during programming to prevent interference, highlighting a practical consideration for circuit design and microcontroller programming.

The final layout can be produced either by printing the Express PCB file onto copper-clad material or by utilizing the Eagle schematic to create a professionally manufactured PCB. This project serves as a comprehensive example of integrating various components in a digital watch application, demonstrating both the challenges and learning opportunities in electronics design and programming.This is my second instructable. I just had a mood of making a digital watch. But wanted to make it a learning process. I already had a sanguino i could have easily used that Atmega644 chip. it would have been more than enough. But i wanted to try burning a Arduino bootloader and see if i could make it work. Well i did. I used a Atmega168 for this project. I used 4 seven segment displays to display time in 24hr format. Here ii experimented with common anode and common cathode. Now i wanted to use other chips too and not just the Arduino which would have been the easier option. The chips i experimented with are 74LS47, 74HC154, 74HC595, 4511 and 74HC139. The final compatible combination was common cathode with 4511 and 74HC139. I used a RTC chip DS1307 to feed the time to the Arduino. I initially wanted to use millis() function in Arduino but it is not that accurate. Using RTC not only saved long coding but also has an added advantage of keeping the time in case the external supply is cutoff.

It uses a 3v battery to do this. I have made the circuit in Eagle but sadly I am not thatproficientin using the software (Which is next on my TO LEARN list) so I didn`t make the board. I have attached the schematic i made on Eagle. U can use it to make the board. I used Express PCB to create the PCB. I have also attached this. pcb file here. You can eitherprint this file directly and make a pcb from a copper clad or build a board from Eagle and get it made professionally.

1) In express PCB fileI`veused JMP at some places. It means you have to use wires to short the two pads. This was necessary since i used a single sided PCB. Confirm where to connect wires from the circuit diagram. 2) At digital pin 0 and 1 i have used jumpers. This is VERY IMPORTANTas the LEDS have to bedisconnectedfrom these points as they are RX and TX pins. LEDs if connected while uploading the program will use up the voltage and hinder the uploading. I learnt it the hard way. So i made changes afterwards. So while uloading Remove the jumpers thus effectively disconnecting them from LEDs and replace them once the uploading is done.

🔗 External reference

The digital watch circuit utilizes an Atmega168 microcontroller to drive four seven-segment displays configured in a common cathode arrangement, interfacing with the 4511 BCD to 7-segment latch/decoder/driver and the 74HC139 dual 2-to-4 line decoder/demultiplexer. The DS1307 real-time clock (RTC) module communicates with the Atmega168 via I2C, ensuring accurate timekeeping and the ability to retain time settings during power loss through a backup battery. The circuit design incorporates pull-up resistors on the I2C lines to ensure reliable communication.

The schematic includes connections for the seven-segment displays, with appropriate current-limiting resistors to prevent excessive current draw. The use of jumpers in the Express PCB file is specified to accommodate the single-sided design, allowing for manual wire connections where necessary. The design emphasizes the importance of disconnecting the LEDs from the RX and TX pins during programming to prevent interference, highlighting a practical consideration for circuit design and microcontroller programming.

The final layout can be produced either by printing the Express PCB file onto copper-clad material or by utilizing the Eagle schematic to create a professionally manufactured PCB. This project serves as a comprehensive example of integrating various components in a digital watch application, demonstrating both the challenges and learning opportunities in electronics design and programming.This is my second instructable. I just had a mood of making a digital watch. But wanted to make it a learning process. I already had a sanguino i could have easily used that Atmega644 chip. it would have been more than enough. But i wanted to try burning a Arduino bootloader and see if i could make it work. Well i did. I used a Atmega168 for this project. I used 4 seven segment displays to display time in 24hr format. Here ii experimented with common anode and common cathode. Now i wanted to use other chips too and not just the Arduino which would have been the easier option. The chips i experimented with are 74LS47, 74HC154, 74HC595, 4511 and 74HC139. The final compatible combination was common cathode with 4511 and 74HC139. I used a RTC chip DS1307 to feed the time to the Arduino. I initially wanted to use millis() function in Arduino but it is not that accurate. Using RTC not only saved long coding but also has an added advantage of keeping the time in case the external supply is cutoff.

It uses a 3v battery to do this. I have made the circuit in Eagle but sadly I am not thatproficientin using the software (Which is next on my TO LEARN list) so I didn`t make the board. I have attached the schematic i made on Eagle. U can use it to make the board. I used Express PCB to create the PCB. I have also attached this. pcb file here. You can eitherprint this file directly and make a pcb from a copper clad or build a board from Eagle and get it made professionally.

1) In express PCB fileI`veused JMP at some places. It means you have to use wires to short the two pads. This was necessary since i used a single sided PCB. Confirm where to connect wires from the circuit diagram. 2) At digital pin 0 and 1 i have used jumpers. This is VERY IMPORTANTas the LEDS have to bedisconnectedfrom these points as they are RX and TX pins. LEDs if connected while uploading the program will use up the voltage and hinder the uploading. I learnt it the hard way. So i made changes afterwards. So while uloading Remove the jumpers thus effectively disconnecting them from LEDs and replace them once the uploading is done.

🔗 External reference