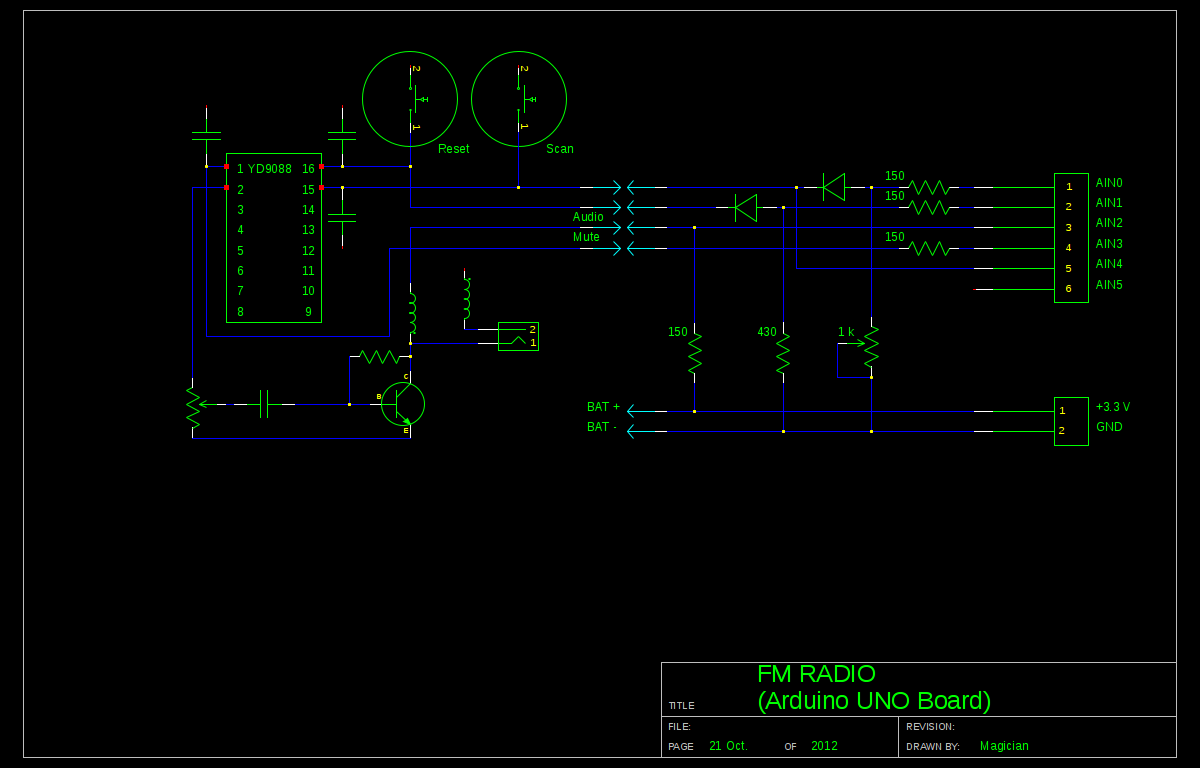

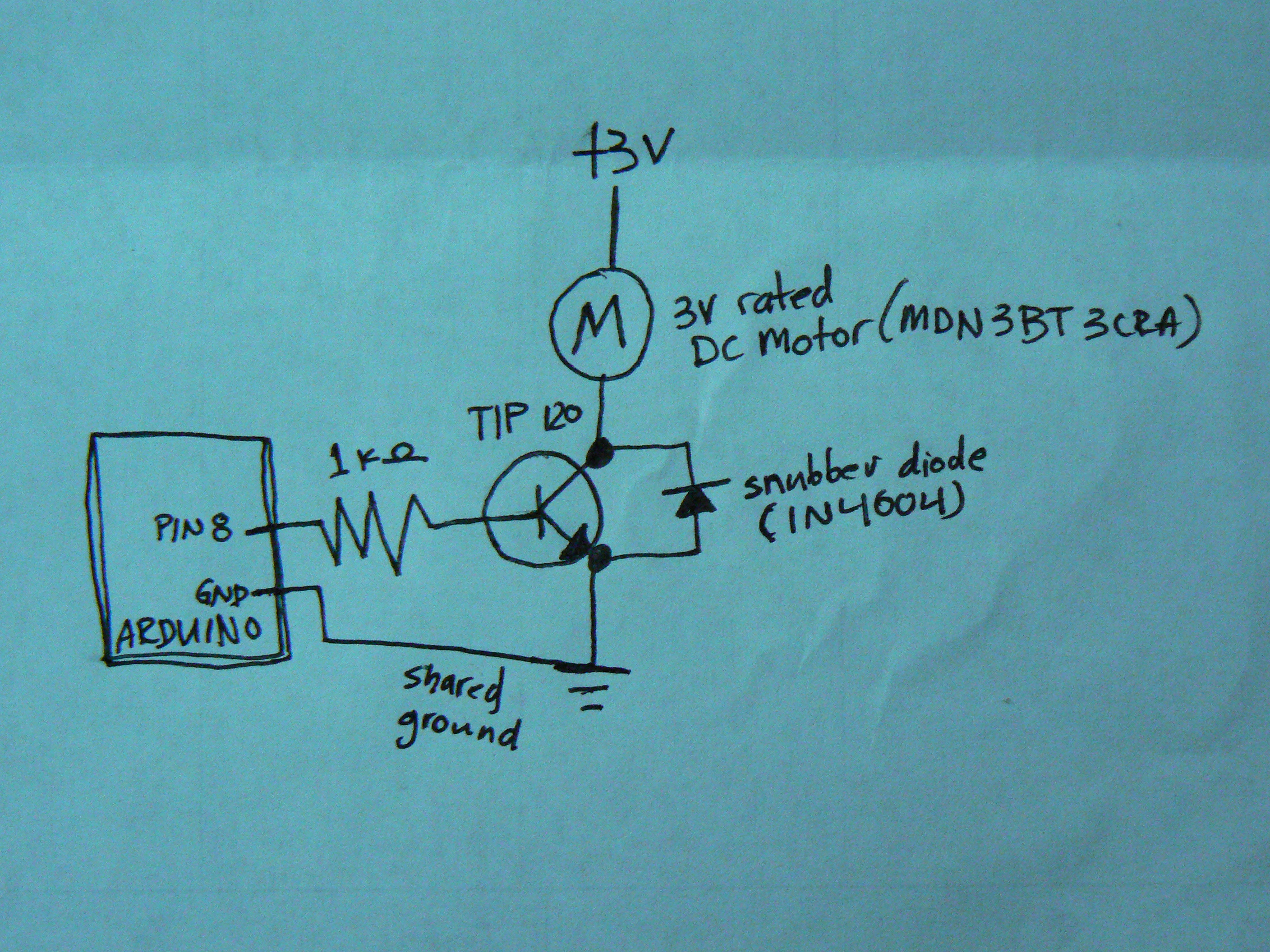

Arduino controlling a DC Motor

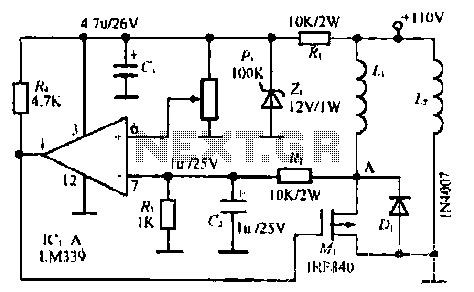

When controlling motors with a microcontroller, the snubber is quite important. This configuration is not commonly seen, as the snubber is typically placed across the motor itself. The general concept is that charge builds up on the motor coil, and when the transistor is turned off, the diode allows current to flow and dissipate the charge. It is suggested to move the diode across the motor for improved results.

In motor control circuits, especially those utilizing microcontrollers, the implementation of snubber circuits is critical for protecting components from voltage spikes and ensuring stable operation. Snubber circuits typically consist of a resistor and capacitor in series, connected across the motor terminals. This configuration helps absorb the inductive kickback generated when the motor is switched off, preventing damage to the microcontroller and other components in the circuit.

When a transistor controlling the motor is turned off, the energy stored in the motor's inductance can generate a high voltage spike. This spike can lead to excessive voltage levels that may damage the transistor or the microcontroller. By placing a diode across the motor, the reverse current can flow through the diode, allowing the energy to dissipate safely. This method effectively clamps the voltage, protecting sensitive components.

For optimal performance, it is advisable to consider the placement of the diode. Moving the diode directly across the motor terminals can enhance the circuit's response to inductive spikes, allowing for quicker dissipation of energy. This adjustment can lead to improved reliability and longevity of the motor control system.

In summary, integrating a snubber circuit and appropriately positioning the diode are essential practices in motor control applications involving microcontrollers. These strategies help mitigate the effects of inductive kickback, ensuring the safe and efficient operation of the motor control system.When controlling motors with a microcontroller (like shown), the snubber is really pretty important. I haven`t seen this configuration, though, and typically the snubber is placed across the motor itself. The general idea is that there is charge that builds up on the motor coil, and, when the transistor is "off", the diode allows a current to flow and the

charge to dissipate. Try moving that diode across the motor for better results. [url= [url= controlling a DC Motor: circuit diagram[/url] by [url= on Flickr

[url= [url= controlling a DC Motor: circuit diagram[/url] by [url= on Flickr  [url= [url= controlling a DC Motor: circuit diagram[/url] by [url= on Flickr

[url= [url= controlling a DC Motor: circuit diagram[/url] by [url= on Flickr  [url= [url= controlling a DC Motor: circuit diagram[/url] by [url= on Flickr

[url= [url= controlling a DC Motor: circuit diagram[/url] by [url= on Flickr  [url= [url= controlling a DC Motor: circuit diagram[/url] by [url= on Flickr

[url= [url= controlling a DC Motor: circuit diagram[/url] by [url= on Flickr  [url= [url= controlling a DC Motor: circuit diagram[/url] by [url= on Flickr

[url= [url= controlling a DC Motor: circuit diagram[/url] by [url= on Flickr  [url= [url= controlling a DC Motor: circuit diagram[/url] by [url= on Flickr

[url= [url= controlling a DC Motor: circuit diagram[/url] by [url= on Flickr  [url= [url= controlling a DC Motor: circuit diagram[/url] by [url= on Flickr [url= controlling a DC Motor: circuit diagram[/url] by [url= on Flickr

[url= [url= controlling a DC Motor: circuit diagram[/url] by [url= on Flickr [url= controlling a DC Motor: circuit diagram[/url] by [url= on Flickr  🔗 External reference

🔗 External reference

In motor control circuits, especially those utilizing microcontrollers, the implementation of snubber circuits is critical for protecting components from voltage spikes and ensuring stable operation. Snubber circuits typically consist of a resistor and capacitor in series, connected across the motor terminals. This configuration helps absorb the inductive kickback generated when the motor is switched off, preventing damage to the microcontroller and other components in the circuit.

When a transistor controlling the motor is turned off, the energy stored in the motor's inductance can generate a high voltage spike. This spike can lead to excessive voltage levels that may damage the transistor or the microcontroller. By placing a diode across the motor, the reverse current can flow through the diode, allowing the energy to dissipate safely. This method effectively clamps the voltage, protecting sensitive components.

For optimal performance, it is advisable to consider the placement of the diode. Moving the diode directly across the motor terminals can enhance the circuit's response to inductive spikes, allowing for quicker dissipation of energy. This adjustment can lead to improved reliability and longevity of the motor control system.

In summary, integrating a snubber circuit and appropriately positioning the diode are essential practices in motor control applications involving microcontrollers. These strategies help mitigate the effects of inductive kickback, ensuring the safe and efficient operation of the motor control system.When controlling motors with a microcontroller (like shown), the snubber is really pretty important. I haven`t seen this configuration, though, and typically the snubber is placed across the motor itself. The general idea is that there is charge that builds up on the motor coil, and, when the transistor is "off", the diode allows a current to flow and the

charge to dissipate. Try moving that diode across the motor for better results.