arduino pwm hb

Connecting and programming the TA8050 DC motor controller with the Arduino microcontroller.

The TA8050 is a versatile DC motor controller designed for use with microcontrollers, such as the Arduino. This controller allows for precise control of DC motors, making it suitable for various applications, including robotics and automation projects. The TA8050 can handle a wide range of input voltages and provides features such as speed control and direction reversal.

To connect the TA8050 to an Arduino, the following steps should be taken:

1. **Power Supply**: Ensure that the TA8050 is powered with an appropriate voltage supply that matches the motor specifications. The power supply should be connected to the VCC and GND terminals of the TA8050.

2. **Motor Connections**: Connect the DC motor to the output terminals of the TA8050. The motor terminals should be connected to the designated output pins, typically labeled as M1 and M2.

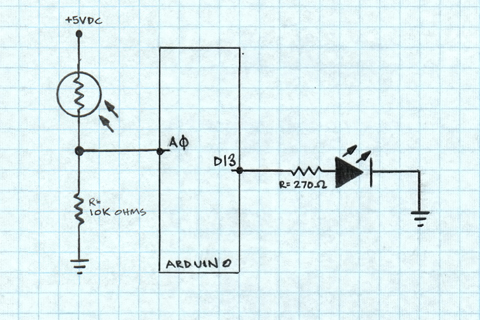

3. **Control Pins**: The TA8050 requires control signals from the Arduino to operate. Connect the control pins (IN1, IN2, PWM) of the TA8050 to the appropriate digital output pins on the Arduino. IN1 and IN2 are used for direction control, while the PWM pin is used for speed control.

4. **Programming the Arduino**: Using the Arduino IDE, upload a sketch that defines the control logic for the motor. The sketch should include functions to set the direction of the motor and adjust the PWM signal for speed control. For example, setting IN1 high and IN2 low would make the motor rotate in one direction, while reversing the signals would change the direction.

5. **Testing**: After uploading the program, test the motor operation by varying the PWM signal to observe the speed control functionality. Additionally, verify the direction control by toggling the IN1 and IN2 pins.

By following these steps, the TA8050 DC motor controller can be effectively integrated with the Arduino microcontroller, allowing for robust control over motor functions in various electronic projects.Connecting and programming the TA8050 DC motor controller with the Arduino microcontroller.. 🔗 External reference

The TA8050 is a versatile DC motor controller designed for use with microcontrollers, such as the Arduino. This controller allows for precise control of DC motors, making it suitable for various applications, including robotics and automation projects. The TA8050 can handle a wide range of input voltages and provides features such as speed control and direction reversal.

To connect the TA8050 to an Arduino, the following steps should be taken:

1. **Power Supply**: Ensure that the TA8050 is powered with an appropriate voltage supply that matches the motor specifications. The power supply should be connected to the VCC and GND terminals of the TA8050.

2. **Motor Connections**: Connect the DC motor to the output terminals of the TA8050. The motor terminals should be connected to the designated output pins, typically labeled as M1 and M2.

3. **Control Pins**: The TA8050 requires control signals from the Arduino to operate. Connect the control pins (IN1, IN2, PWM) of the TA8050 to the appropriate digital output pins on the Arduino. IN1 and IN2 are used for direction control, while the PWM pin is used for speed control.

4. **Programming the Arduino**: Using the Arduino IDE, upload a sketch that defines the control logic for the motor. The sketch should include functions to set the direction of the motor and adjust the PWM signal for speed control. For example, setting IN1 high and IN2 low would make the motor rotate in one direction, while reversing the signals would change the direction.

5. **Testing**: After uploading the program, test the motor operation by varying the PWM signal to observe the speed control functionality. Additionally, verify the direction control by toggling the IN1 and IN2 pins.

By following these steps, the TA8050 DC motor controller can be effectively integrated with the Arduino microcontroller, allowing for robust control over motor functions in various electronic projects.Connecting and programming the TA8050 DC motor controller with the Arduino microcontroller.. 🔗 External reference