Arduino Based Current Sensor Circuit

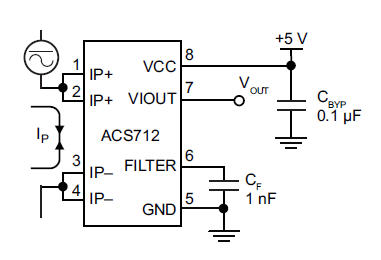

The primary component utilized is the ACS712 sensor from Allegro MicroSystems, designed for measuring current. It offers cost-effective and accurate solutions for AC or DC current sensing in industrial, commercial, and communication systems. A precise, low-offset, linear Hall sensor is situated near the surface of the die, along with a copper conduction path. This device is not intended for automotive applications; however, it is commonly employed in motor control, switched-mode power supplies, overcurrent fault protection, and load detection and management. The project utilizes one of the three available models of the ACS712, with different models selectable based on the maximum current to be measured (5A, 20A, or 30A). According to its pin configuration, the voltage across the VIOUT and ground pin is proportional to the current flowing between IP+ and IP-, making the ACS712 straightforward to implement. It requires two capacitors for filtering the power supply and output and operates on a 5V power supply. For the 5A model, the sensitivity, which relates the output voltage to input current measurements, has a typical value of 185mV/A. This value is read by an Arduino and converted using a specific formula. The results are then transmitted via a serial connection to a personal computer, allowing data visualization through Analog Demo software for real-time updates. Sensor accuracy can be validated using a microcontrolled battery charger.

The ACS712 current sensor operates by utilizing the Hall effect to detect the magnetic field generated by the current flowing through the copper conduction path. This allows for non-intrusive current measurement, which is particularly advantageous in applications where direct contact with the current-carrying conductor is impractical or unsafe. The device's linear output voltage is directly proportional to the measured current, facilitating easy integration with microcontrollers such as Arduino.

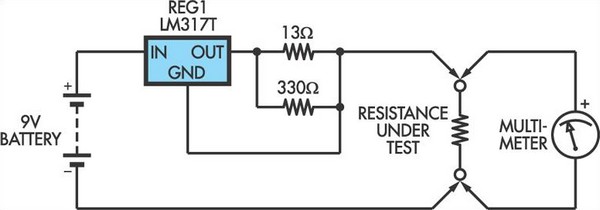

To implement the ACS712 in a circuit, it is essential to connect the IP+ and IP- pins in series with the load whose current is to be measured. The VIOUT pin provides an output voltage that varies with the current flow, which can be read by an analog input pin on the Arduino. The required filtering capacitors help to stabilize the power supply and the output signal, reducing noise and improving measurement accuracy.

The Arduino processes the output voltage from the ACS712 using a defined formula to convert the analog voltage reading into a current measurement. This calculated current can then be displayed in real-time on a computer screen via a serial connection, providing valuable insights into the performance of the monitored system. The use of software like Analog Demo allows for graphical representation of the current over time, enabling users to analyze trends and anomalies effectively.

In terms of accuracy, the ACS712 is designed to operate within specified limits, and its performance can be validated against known current sources, such as a microcontrolled battery charger. This validation process ensures that the system operates correctly and that the readings are reliable for the intended application. Overall, the ACS712 sensor presents a versatile and efficient solution for current sensing in various electronic applications.The main component used is the ACS712 sensor from Allegro MicroSystems to measure the current. It provides economical and precise solutions for AC or DC current sensing in industrial, commercial and communications systems. Located near the surface of the die of the device is a precise, low-offset, linear Hall sensor with a copper conduction path.

The device is not intended for automotive applications but is typically used in motor control, switched-mode power supplies, over current fault protection, load detection and management. This project uses one of the three models of ACS712. Other models can be chosen depending on the maximum measured current (5-20-30A). From its pin configuration, the voltage across VIOUT and ground PIN is proportional to current flowing between IP+ and IP-, which makes ACS712 very easy to use.

It needs two capacitors for filtering the power supply and output while requiring a power supply of 5V. For 5A model, the value that links the proportionality of output voltage and input current measurements is sensitivity which has a typical value of 185mV/A.

The value is read by Arduino and is converted with a formula. The result is sent via serial connection to a personal computer. The data can be plotted to a chart using Analog Demo software and keep an updated feed. Sensor accuracy can be tested using a microcontrolled battery charger. 🔗 External reference

The ACS712 current sensor operates by utilizing the Hall effect to detect the magnetic field generated by the current flowing through the copper conduction path. This allows for non-intrusive current measurement, which is particularly advantageous in applications where direct contact with the current-carrying conductor is impractical or unsafe. The device's linear output voltage is directly proportional to the measured current, facilitating easy integration with microcontrollers such as Arduino.

To implement the ACS712 in a circuit, it is essential to connect the IP+ and IP- pins in series with the load whose current is to be measured. The VIOUT pin provides an output voltage that varies with the current flow, which can be read by an analog input pin on the Arduino. The required filtering capacitors help to stabilize the power supply and the output signal, reducing noise and improving measurement accuracy.

The Arduino processes the output voltage from the ACS712 using a defined formula to convert the analog voltage reading into a current measurement. This calculated current can then be displayed in real-time on a computer screen via a serial connection, providing valuable insights into the performance of the monitored system. The use of software like Analog Demo allows for graphical representation of the current over time, enabling users to analyze trends and anomalies effectively.

In terms of accuracy, the ACS712 is designed to operate within specified limits, and its performance can be validated against known current sources, such as a microcontrolled battery charger. This validation process ensures that the system operates correctly and that the readings are reliable for the intended application. Overall, the ACS712 sensor presents a versatile and efficient solution for current sensing in various electronic applications.The main component used is the ACS712 sensor from Allegro MicroSystems to measure the current. It provides economical and precise solutions for AC or DC current sensing in industrial, commercial and communications systems. Located near the surface of the die of the device is a precise, low-offset, linear Hall sensor with a copper conduction path.

The device is not intended for automotive applications but is typically used in motor control, switched-mode power supplies, over current fault protection, load detection and management. This project uses one of the three models of ACS712. Other models can be chosen depending on the maximum measured current (5-20-30A). From its pin configuration, the voltage across VIOUT and ground PIN is proportional to current flowing between IP+ and IP-, which makes ACS712 very easy to use.

It needs two capacitors for filtering the power supply and output while requiring a power supply of 5V. For 5A model, the value that links the proportionality of output voltage and input current measurements is sensitivity which has a typical value of 185mV/A.

The value is read by Arduino and is converted with a formula. The result is sent via serial connection to a personal computer. The data can be plotted to a chart using Analog Demo software and keep an updated feed. Sensor accuracy can be tested using a microcontrolled battery charger. 🔗 External reference