arduino scr

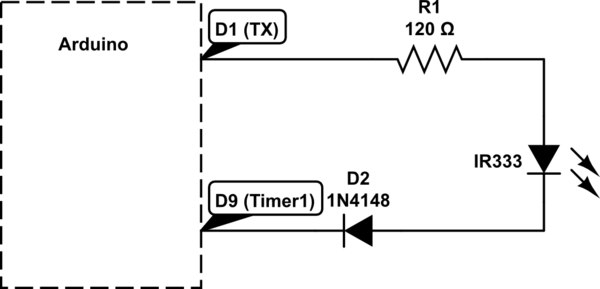

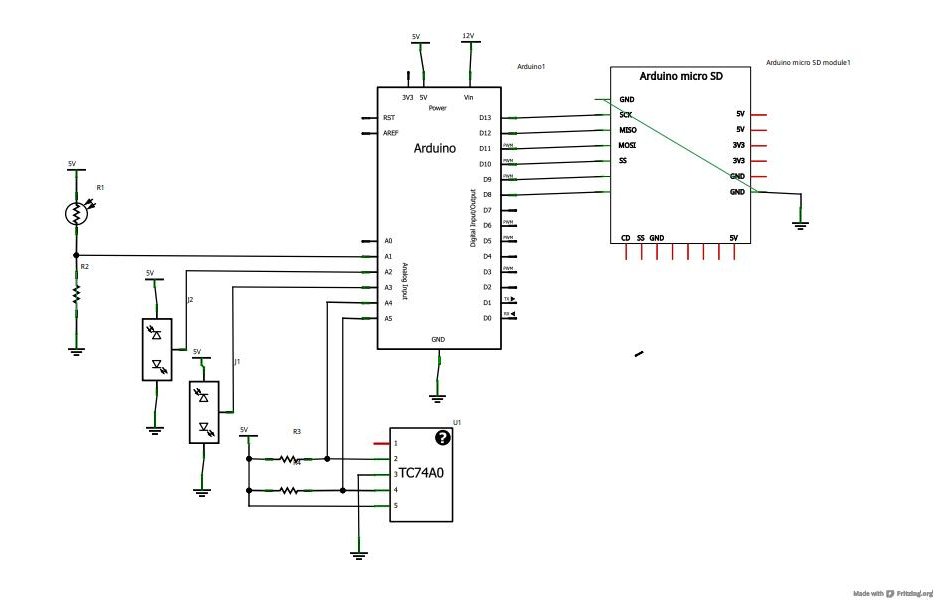

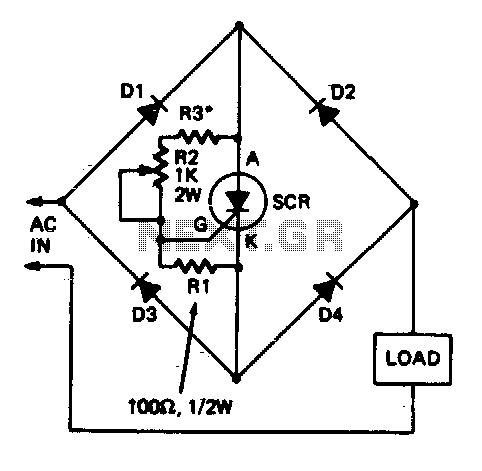

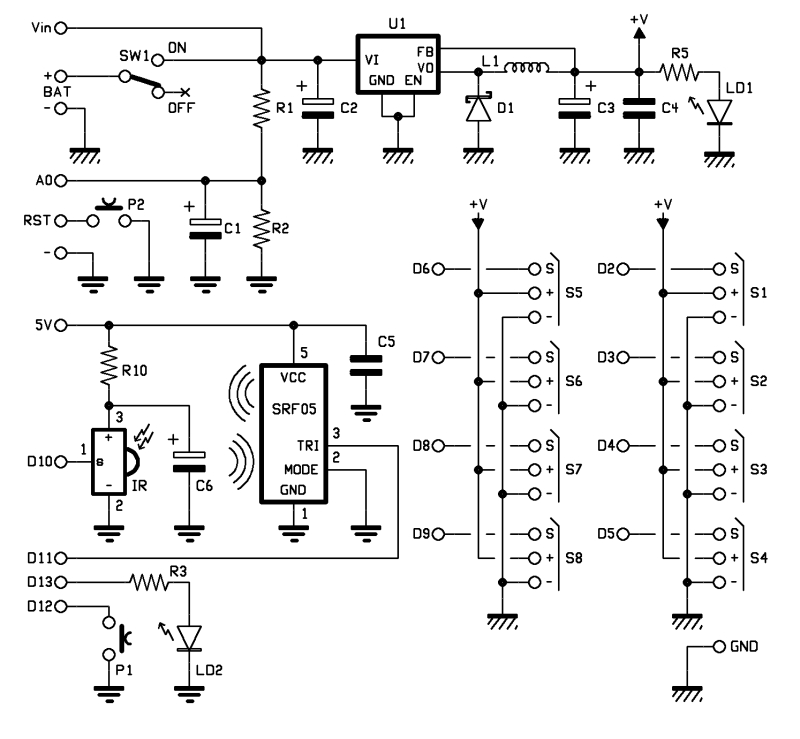

This circuit demonstrates the use of Silicon Controlled Rectifiers (SCRs) to control low-voltage pulsating DC for operating homemade LED light panels. Although the circuit utilizes an Arduino, the underlying concepts are applicable to various microcontrollers, whether through hardware interrupts or polling. It is essential to employ pulsating DC, as SCRs will not function correctly without it. In the main circuit diagram, transformer T1, diodes D1 and D3 generate a positive pulsating DC with a peak voltage of approximately 18 volts and a frequency of 120 Hertz. Diode D2 prevents the filtering effect of capacitor C2, which, along with U2, provides a positive five volts for the microcontroller. The 4N25 opto-coupler delivers a narrow pulse at zero and 180 degrees of the sine wave, which is fed to digital pin 2 (Dp2) of the controller to trigger an interrupt when the sine wave crosses these points. A full sine wave spans 360 degrees. The CdS photocell, along with resistors R6 and R3, forms a voltage divider. As light intensity increases, the resistance of R6 decreases, resulting in a voltage rise at the junction of R3, R6, and the analog-to-digital converter pin Ad0 on the controller. R3 can be a 10k resistor, which is the value used in this circuit. The 10-bit ADC converts this voltage into a value between 0 and 1023, which is utilized in a delay routine to determine the SCR firing point. A longer delay corresponds to reduced power to the LED strings and lower light output. When the power switch at Dp4 is pressed, a 100 microsecond positive pulse is sent to the H11C6 opto-coupler through a 470-ohm resistor. This pulse triggers the SCR at the desired time during the delay, occurring 120 times per second. The H11C6 contains an LED light source that activates the light-activated silicon-controlled rectifier (LASCR), which in turn fires the main power SCR Q1. Resistor R5 limits the gate current of Q1, while R7 and R8 restrict the current flowing through the LED strings. The LED strings consist of four high-intensity white LEDs connected in series. With each LED operating at 3 to 3.5 volts, the series configuration requires 12 to 14 volts. In this setup, Q1 is a S4015L SCR rated for 400 volts and capable of handling 15 amperes of current, which allows for the operation of multiple LED strings.

The circuit utilizes specific pin definitions for control and input, including triac_control (pin 5), powerIndicator (pin 12), sensorPin (pin 0), irq_Pin (pin 2), and powerOn (pin 4). A volatile byte flag_bit1 is declared to manage the interrupt request (IRQ) flag, while an integer variable analogValue is initialized to store the analog reading from the sensor. The setup function configures the pin modes and initializes the digital states for the triac control and power indicator LEDs. The attachInterrupt function links the interrupt service routine to the specified pin, allowing for real-time response to the zero-crossing signal from the opto-coupler.

In the loop function, the state of the powerOn pin is monitored, and the power indicator LED is activated accordingly. If the flag_bit1 indicates an interrupt has occurred and the powerOn pin is low, the analog value from the sensor is read, and a delay is introduced based on this value to determine the SCR firing time. The triac is turned on and off with precise timing, allowing for effective control of the LED brightness. The flag is then cleared to prepare for the next interrupt. The flag1 function sets the interrupt flag, enabling the loop to respond to the next zero-crossing event.In this circuit we demonstrate how to use SCRs to control low-voltage pulsating DC to operate homemade LED light panels. While in this circuit I use the Arduino, the concepts should work with any number of micro-controllers using either hardware interrupts or polling.

We must use pulsating DC or the SCR won`t operate properly. See Basic SCRs/Triac s. In the main circuit diagram above transformer T1, D1, and D3 produce a positive going pulsating DC with a peak voltage of about 18 volts and a frequency of 120 Hertz. Diode D2 blocks the filtering effect of capacitor C2, which with U2 supplies positive five volts for the microcontroller.

See Basic AC Rectification and Filtering The 4N25 opto-coupler provides a narrow 120 Hertz pulse at zero and 180 degrees of the sine wave. This pulse is fed to digital pin 2 (Dp2) of the controller to trigger an interrupt when the sine wave passes zero and 180 degrees.

(There`s 360 degrees in a sine wave. ) See 4N25 Opto-Coupler (PDF file) CdS photocell R6 and R3 form a voltage divider. As light intensity increases the resistance of R6 decreases causing the voltage to rise at the junction of R3, R6, and analog to digital converter pin Ad0 on the controller. (R3 can be a 10k resistor, which is what I used. ) When read by the program this 10-bit AD converter will produce a value between 0 and 1023. This value is used in a delay routine to determines the firing point of the SCR. The longer the delay, the less power to the LED strings and less light output. See Using a CdS Photocells When the power on switch is pressed at Dp4 a 100 uSec. positive-going pulse is sent to the H11C6 opto-coupler through a 470 ohm resistor. This in turn fires the SCR at the desired time during the delay time 120 times per second. The H11C6 contains a LED light source used to fire the light activated silicon-controlled rectifier (LASCR) in order to fire the main power SCR Q1.

R5 limits the gate current of Q1 while R7 and R8 limit the current in the LED strings. See H11C6 spec sheet. (PDF file) The LED strings are composed of four high intensity white LEDs in series. At 3 to 3. 5 volts each four in series operate at 12-14 volts. Q1 used in this test was a S4015L 400 volt SCR that can handle 15 amperes of current. That can handle a lot of LED strings. // LED must be connected between digital pin and ground #define triac_control 5 #define powerIndicator 12 // indicator #define sensorPin 0 // potentiometer #define irq_Pin 2 #define powerOn 4 // when using values in the main routine // and IRQ routine must be volatile value volatile byte flag_bit1 = LOW; // declare IRQ flag int analogValue = 0; // HIGH = 1, LOW = 0 void setup() { pinMode(triac_control, OUTPUT); pinMode(powerIndicator, OUTPUT); digitalWrite(triac_control, 0); // LED off digitalWrite(powerIndicator, 0); // LED off pinMode(irq_Pin, INPUT); pinMode(powerOn, INPUT); digitalWrite(irq_Pin, 1); // pull up on digitalWrite(powerOn, 1); // pull up on attachInterrupt(0, flag1, FALLING); // interrupt 0 digital pin 2 connected ZC circuit } void loop() { if (!digitalRead(powerOn) digitalWrite(powerIndicator, 1); else digitalWrite(powerIndicator, 0); if (flag_bit1 = 1) && (digitalRead(powerOn)= 0) { analogValue = analogRead(sensorPin); delayMicroseconds(analogValue * 7 + 500); // set value between 4 and 14 digitalWrite(triac_control, 1); //triac on delayMicroseconds(100); digitalWrite(triac_control, 0); //triac off flag_bit1 = 0; // clear flag } } // end loop void flag1() // set bit { flag_bit1 = 1; } 🔗 External reference

The circuit utilizes specific pin definitions for control and input, including triac_control (pin 5), powerIndicator (pin 12), sensorPin (pin 0), irq_Pin (pin 2), and powerOn (pin 4). A volatile byte flag_bit1 is declared to manage the interrupt request (IRQ) flag, while an integer variable analogValue is initialized to store the analog reading from the sensor. The setup function configures the pin modes and initializes the digital states for the triac control and power indicator LEDs. The attachInterrupt function links the interrupt service routine to the specified pin, allowing for real-time response to the zero-crossing signal from the opto-coupler.

In the loop function, the state of the powerOn pin is monitored, and the power indicator LED is activated accordingly. If the flag_bit1 indicates an interrupt has occurred and the powerOn pin is low, the analog value from the sensor is read, and a delay is introduced based on this value to determine the SCR firing time. The triac is turned on and off with precise timing, allowing for effective control of the LED brightness. The flag is then cleared to prepare for the next interrupt. The flag1 function sets the interrupt flag, enabling the loop to respond to the next zero-crossing event.In this circuit we demonstrate how to use SCRs to control low-voltage pulsating DC to operate homemade LED light panels. While in this circuit I use the Arduino, the concepts should work with any number of micro-controllers using either hardware interrupts or polling.

We must use pulsating DC or the SCR won`t operate properly. See Basic SCRs/Triac s. In the main circuit diagram above transformer T1, D1, and D3 produce a positive going pulsating DC with a peak voltage of about 18 volts and a frequency of 120 Hertz. Diode D2 blocks the filtering effect of capacitor C2, which with U2 supplies positive five volts for the microcontroller.

See Basic AC Rectification and Filtering The 4N25 opto-coupler provides a narrow 120 Hertz pulse at zero and 180 degrees of the sine wave. This pulse is fed to digital pin 2 (Dp2) of the controller to trigger an interrupt when the sine wave passes zero and 180 degrees.

(There`s 360 degrees in a sine wave. ) See 4N25 Opto-Coupler (PDF file) CdS photocell R6 and R3 form a voltage divider. As light intensity increases the resistance of R6 decreases causing the voltage to rise at the junction of R3, R6, and analog to digital converter pin Ad0 on the controller. (R3 can be a 10k resistor, which is what I used. ) When read by the program this 10-bit AD converter will produce a value between 0 and 1023. This value is used in a delay routine to determines the firing point of the SCR. The longer the delay, the less power to the LED strings and less light output. See Using a CdS Photocells When the power on switch is pressed at Dp4 a 100 uSec. positive-going pulse is sent to the H11C6 opto-coupler through a 470 ohm resistor. This in turn fires the SCR at the desired time during the delay time 120 times per second. The H11C6 contains a LED light source used to fire the light activated silicon-controlled rectifier (LASCR) in order to fire the main power SCR Q1.

R5 limits the gate current of Q1 while R7 and R8 limit the current in the LED strings. See H11C6 spec sheet. (PDF file) The LED strings are composed of four high intensity white LEDs in series. At 3 to 3. 5 volts each four in series operate at 12-14 volts. Q1 used in this test was a S4015L 400 volt SCR that can handle 15 amperes of current. That can handle a lot of LED strings. // LED must be connected between digital pin and ground #define triac_control 5 #define powerIndicator 12 // indicator #define sensorPin 0 // potentiometer #define irq_Pin 2 #define powerOn 4 // when using values in the main routine // and IRQ routine must be volatile value volatile byte flag_bit1 = LOW; // declare IRQ flag int analogValue = 0; // HIGH = 1, LOW = 0 void setup() { pinMode(triac_control, OUTPUT); pinMode(powerIndicator, OUTPUT); digitalWrite(triac_control, 0); // LED off digitalWrite(powerIndicator, 0); // LED off pinMode(irq_Pin, INPUT); pinMode(powerOn, INPUT); digitalWrite(irq_Pin, 1); // pull up on digitalWrite(powerOn, 1); // pull up on attachInterrupt(0, flag1, FALLING); // interrupt 0 digital pin 2 connected ZC circuit } void loop() { if (!digitalRead(powerOn) digitalWrite(powerIndicator, 1); else digitalWrite(powerIndicator, 0); if (flag_bit1 = 1) && (digitalRead(powerOn)= 0) { analogValue = analogRead(sensorPin); delayMicroseconds(analogValue * 7 + 500); // set value between 4 and 14 digitalWrite(triac_control, 1); //triac on delayMicroseconds(100); digitalWrite(triac_control, 0); //triac off flag_bit1 = 0; // clear flag } } // end loop void flag1() // set bit { flag_bit1 = 1; } 🔗 External reference