Robot shield for Arduino

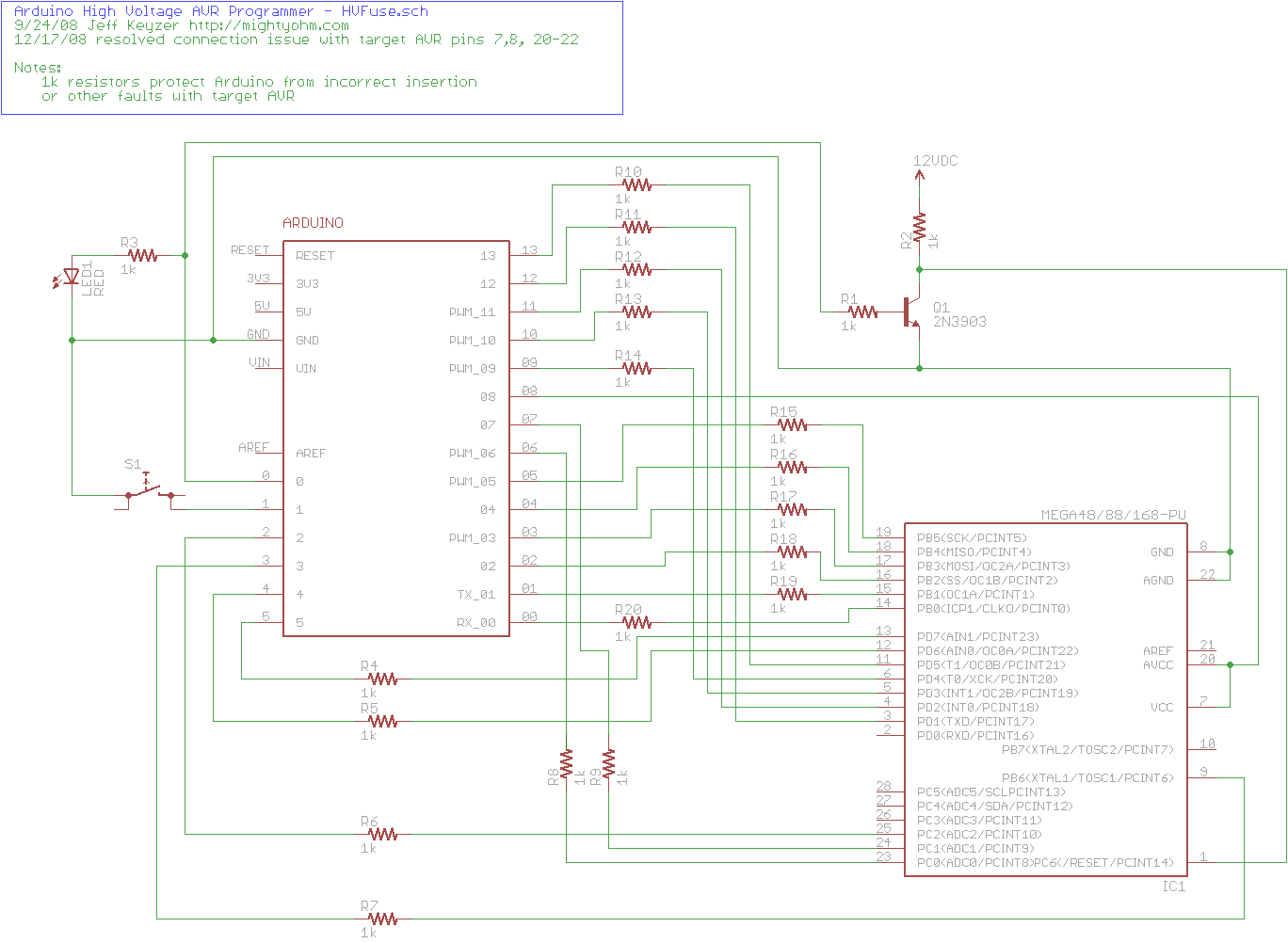

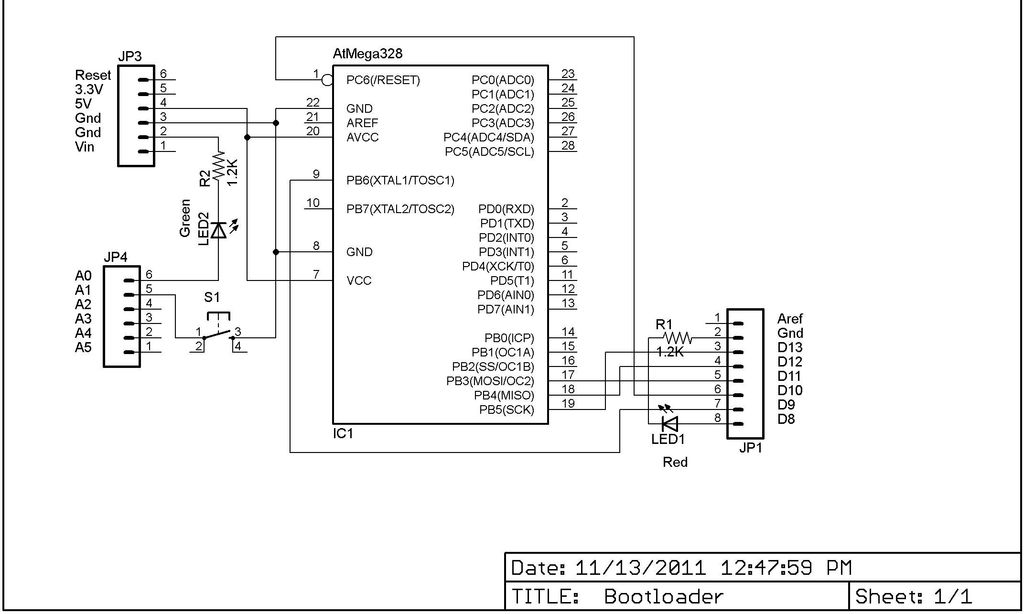

The objective of this project is to consolidate various robot designs and transform them into a new device featuring updated hardware and standardized software, specifically utilizing Arduino for ease of use. These robots share three key components: a mechanical structure, hardware, and software. While the mechanical aspects will differ, the goal is to determine if a common hardware board can be established with a unified development system. The Arduino board is the clear choice, as its development environment is ideal for creating similar projects. One of the initial considerations is that the Arduino board can manage a significant number of servos, with the SPIDER robot utilizing eight. The Arduino can be powered through a plug with a voltage range of 6 to 12 volts, and its voltage regulator provides a stabilized 5V output necessary for the operation of the shield. It is feasible to power the robot using rechargeable batteries. A standard servo requires a supply voltage of 4.8 to 6 volts, which can be easily achieved with four batteries in series. Fully charged, these batteries provide 1.5V each, totaling 6 volts, but as they discharge, the output drops to 1.0V per cell, resulting in 4 volts, which is not optimal for the servos. Consequently, a specialized shield was developed, designed for these functions, making installation and usage straightforward. The robot can be powered by a single battery pack with a voltage range of 6 to 12 volts, such as two LiPo cells or 6-8 NiMH or NiCd cells. Since the servos operate at 5 volts, a stabilized voltage must be derived from the 6-12 volt input. The optimal solution involves using a switching step-down regulator, which ensures efficiency exceeding 80% under various conditions. The integrated LM2576-5 contains all necessary components to build a switching power supply; only an inductor, a diode, and a capacitor need to be added. This regulator can deliver a maximum current of 3A and accepts input voltages from 4 to 40 volts. The wiring diagram includes a BAT connector to connect the battery pack to the switch and the LM2576 voltage regulator. Resistor R5 and LED LD1 are used solely to indicate voltage presence. The stabilized output voltage from the LM2576 powers all servos, while the Arduino is powered directly from the battery pack via Vin, taken just after the switch. To monitor battery voltage, an analog input on the Arduino (A0) is utilized. Resistors R1 and R2 are used to scale the voltage down from 0-20 volts to a 0-5 volt range. The selected resistor values allow for a simple calculation: dividing the acquired analog voltage by 50 yields the actual voltage in volts. For obstacle detection, the ultrasonic sensor model SRF05 was chosen due to its design resembling two eyes, enhancing the robot's aesthetic appeal. This sensor operates using a digital line connected to PIN11. An economical infrared system is selected for remote control, requiring the installation of an IR receiver compatible with standard commercial remote controls, such as the PNA4602. A typical remote control used for TVs or VCRs can be employed to send commands to the robot easily and cost-effectively. The shield includes an Arduino reset button, a general-use button, and an LED connected to pin 13 of the Arduino. The Filippo biped robot, which operates using only two servos, allows for experimentation in robotics without significant financial investment. It can walk and turn, being directed in any direction, which helps beginners familiarize themselves with servos and their interaction with mechanical components. The assembly process is simplified, as all pieces fit together, requiring only a fastening method, which can include epoxy glue for permanent attachment.The idea behind this post is to bring together some robot designs and trasform them in a new device with new hardware and standard software (arduino of course) and so easier to use. These robots have three things in common: a mechanical structure, the hardware and the software. While the mechanical part is necessarily different, we wanted to under stand if there was a hardware board that could be common, with a unique development system. The choice, quite obviously, has the Arduino board, which with its development environment is perfect to create similar projects. The first consideration that came to our mind is like the Arduino board can manage a large number of servos, eight in the case of the robot SPIDER.

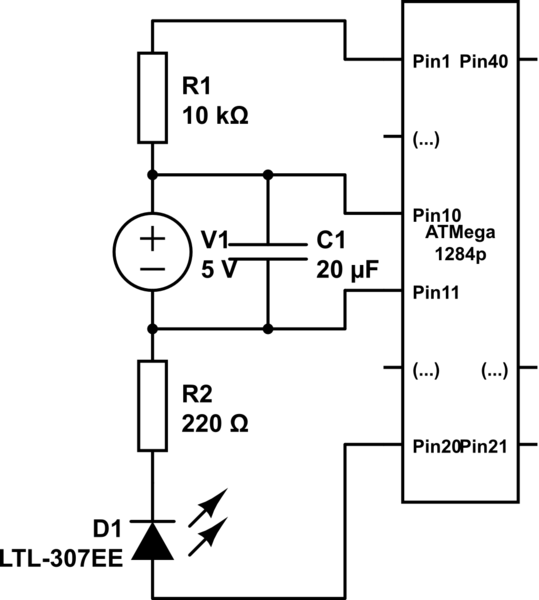

Arduino can be powered through the plug with a voltage between 6 to 12 volts, his voltage regulator provides the 5 V stabilized, necessary for the operation of our shield. We could power our robot with rechargeable batteries. A standard servo requires a supply voltage of 4. 8 to 6 volts, easily obtainable with four batteries in series, at full charge, provide 1. 5 x 4 = 6 volts but towards the complete discharge provide just 1. 0 x 4 = 4 volts. We are not in optimal conditions for the servos. Throughout this reasons we decided to create a special shield, already prepared for all these functions, it is easy to install and use.

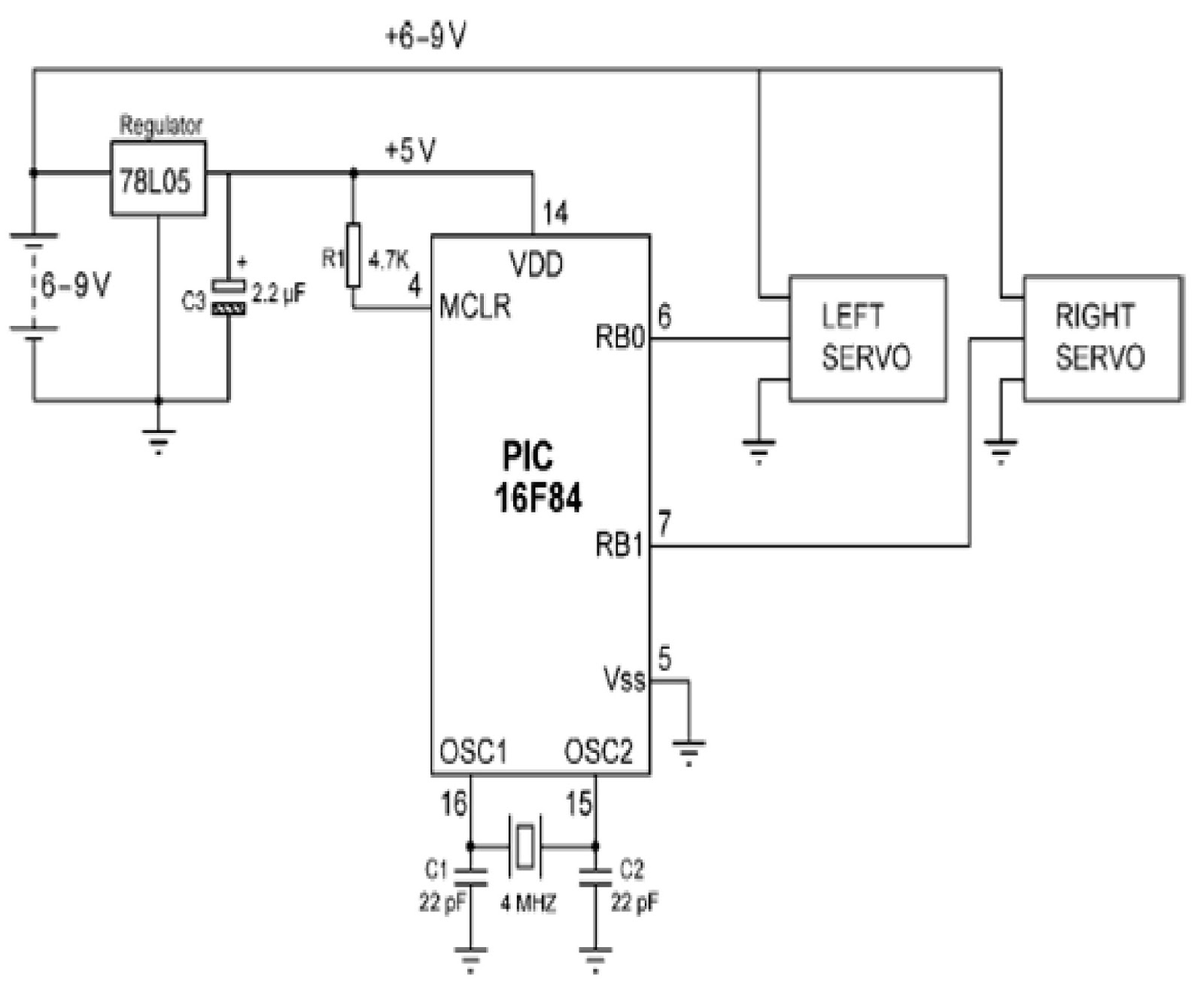

We can assume to power our robot with a single battery pack with a voltage between 6 and 12 volts, so for example two cells or 6-8 LiPo NiMh or NiCd cells. The servos works at 5Volt, so we should get this stabilized voltage starting from input voltage of 6-12 volts.

The optimal solution is the use of a switching step-down regulatorwhich ensures efficiency exceeding 80% in every situation. Just the integrated LM2576-5 contains all the elements to build a switching power supply, just add an inductor, a diode and a capacitor.

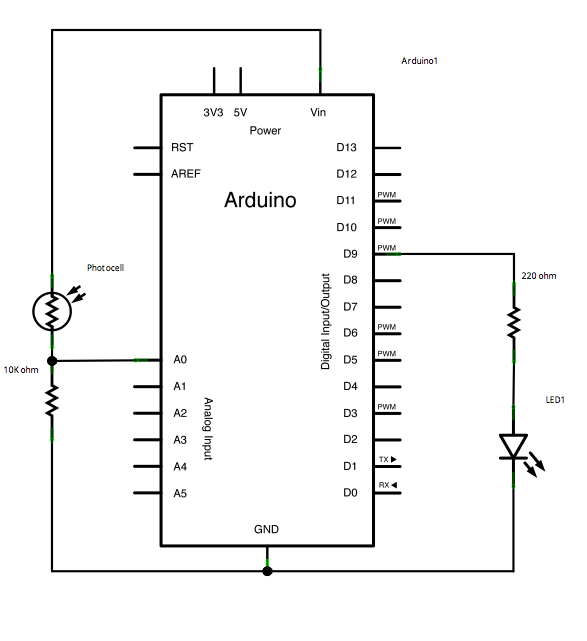

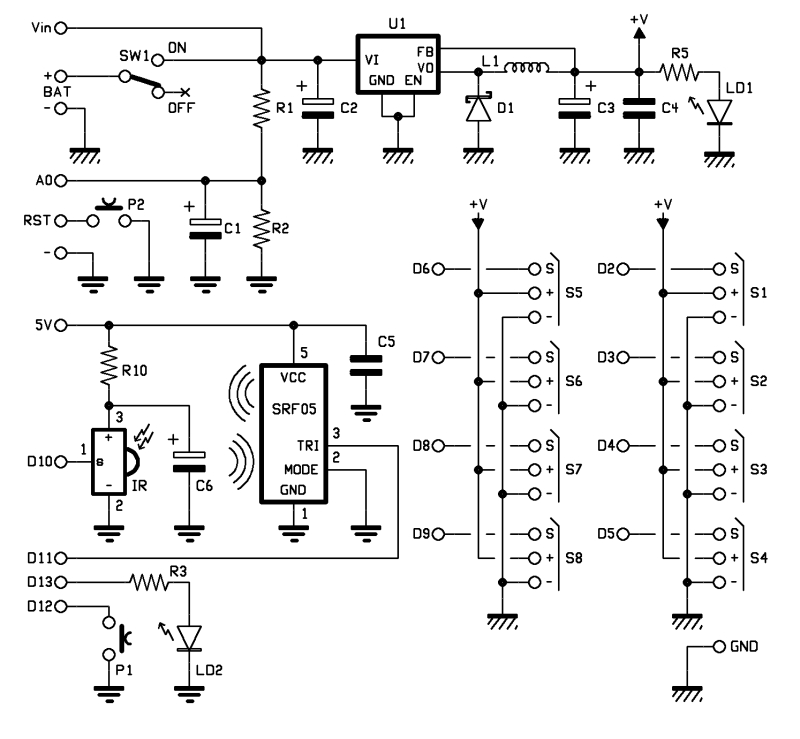

It can deliver a maximum current of 3A and accepts input voltages between 4 and 40volt. Analysing the wiring diagram you can see the connector BAT which will connect the battery pack to the switch and the voltage regulator LM2576, the resistance R5 and the led LD1 are used only to detect the presence of the voltage. The stabilized voltage output from the LM2576 will be used to power all the servos, while the Arduino is powered directly from the battery pack, taking the tension just after the switch (Vin).

For reading the battery voltage will use an analog input of Arduino (A0). The two resistors R1 and R2 reduce the voltage to a value between 0 and 20 volts to a value of 0-5Volt. We chose these specific values of resistance because, by reading the analog voltage with Arduino, it is sufficient to divide the data acquired by 50 to obtain the value of the voltage in volts.

As obstacle sensor we chose the ultrasonic sensor model SRF05 that, thanks to its shape, recalls two eyes and improves the aesthetic appearance of our robot. To operate, we use a digital line connected to PIN11. As remote control we opt for a economical infrared system; is sufficient to install an IR receiver compatible with the normal commercial remote controls, such as the integrated PNA4602.

It will be sufficient a normal remote control of those used for TVs or VCRs to send commands to our robot in a simple and economic way. The shield provides the Arduino reset button, a button for general use and a LED connected to pin 13 of Arduino.

Filippo is a biped robot whose movements are assigned to only two servos, but with this robot you can experiment with robotics without spending large sums. It is able to walk and turn around, then you can direct it in any direction, enabling those who are beginning to become familiar with the servos and how they can interact with mechanical parts.

Its assembly is facilitated because all the pieces fit over each other and it is sufficient sorder to fix them permanently, as an alternative you can use the epoxy glue. Afte 🔗 External reference

Arduino can be powered through the plug with a voltage between 6 to 12 volts, his voltage regulator provides the 5 V stabilized, necessary for the operation of our shield. We could power our robot with rechargeable batteries. A standard servo requires a supply voltage of 4. 8 to 6 volts, easily obtainable with four batteries in series, at full charge, provide 1. 5 x 4 = 6 volts but towards the complete discharge provide just 1. 0 x 4 = 4 volts. We are not in optimal conditions for the servos. Throughout this reasons we decided to create a special shield, already prepared for all these functions, it is easy to install and use.

We can assume to power our robot with a single battery pack with a voltage between 6 and 12 volts, so for example two cells or 6-8 LiPo NiMh or NiCd cells. The servos works at 5Volt, so we should get this stabilized voltage starting from input voltage of 6-12 volts.

The optimal solution is the use of a switching step-down regulatorwhich ensures efficiency exceeding 80% in every situation. Just the integrated LM2576-5 contains all the elements to build a switching power supply, just add an inductor, a diode and a capacitor.

It can deliver a maximum current of 3A and accepts input voltages between 4 and 40volt. Analysing the wiring diagram you can see the connector BAT which will connect the battery pack to the switch and the voltage regulator LM2576, the resistance R5 and the led LD1 are used only to detect the presence of the voltage. The stabilized voltage output from the LM2576 will be used to power all the servos, while the Arduino is powered directly from the battery pack, taking the tension just after the switch (Vin).

For reading the battery voltage will use an analog input of Arduino (A0). The two resistors R1 and R2 reduce the voltage to a value between 0 and 20 volts to a value of 0-5Volt. We chose these specific values of resistance because, by reading the analog voltage with Arduino, it is sufficient to divide the data acquired by 50 to obtain the value of the voltage in volts.

As obstacle sensor we chose the ultrasonic sensor model SRF05 that, thanks to its shape, recalls two eyes and improves the aesthetic appearance of our robot. To operate, we use a digital line connected to PIN11. As remote control we opt for a economical infrared system; is sufficient to install an IR receiver compatible with the normal commercial remote controls, such as the integrated PNA4602.

It will be sufficient a normal remote control of those used for TVs or VCRs to send commands to our robot in a simple and economic way. The shield provides the Arduino reset button, a button for general use and a LED connected to pin 13 of Arduino.

Filippo is a biped robot whose movements are assigned to only two servos, but with this robot you can experiment with robotics without spending large sums. It is able to walk and turn around, then you can direct it in any direction, enabling those who are beginning to become familiar with the servos and how they can interact with mechanical parts.

Its assembly is facilitated because all the pieces fit over each other and it is sufficient sorder to fix them permanently, as an alternative you can use the epoxy glue. Afte 🔗 External reference