Arduino Thermostat

This is a brief update regarding a project that is currently incomplete. The thermostat for the central heating system in the house has become unreliable recently. A new unit from the heater's manufacturer was quoted at $450 AUD, prompting the decision to create a custom solution. The initial version of the project has been installed, with the board layout and manufacturing handled by Doug. The next component intended for integration into the home system is a pair of hygrometers, one for outdoor use and another for indoor use. This addition is particularly relevant given the use of evaporative cooling; monitoring outdoor humidity levels can help prevent excess moisture in the air, which could potentially damage books and create an uncomfortable environment. Two HS1101 humidity sensors were acquired at a low cost, which measure capacitance that varies with relative humidity. A temperature sensor, Dallas 1820, was also included in the design. The circuit utilizes a 1-Wire pin for temperature data and another pin for humidity measurement, powered down when not in use to minimize noise, as suggested by Peter H. Anderson. The construction of the circuit presented challenges, particularly in selecting the correct resistor values for the LMC555 timer and ensuring compatibility with a CMOS version of the timer. Calibration issues have been encountered, but the development of an identical sensor for indoor use may provide a solution for monitoring humidity levels effectively.

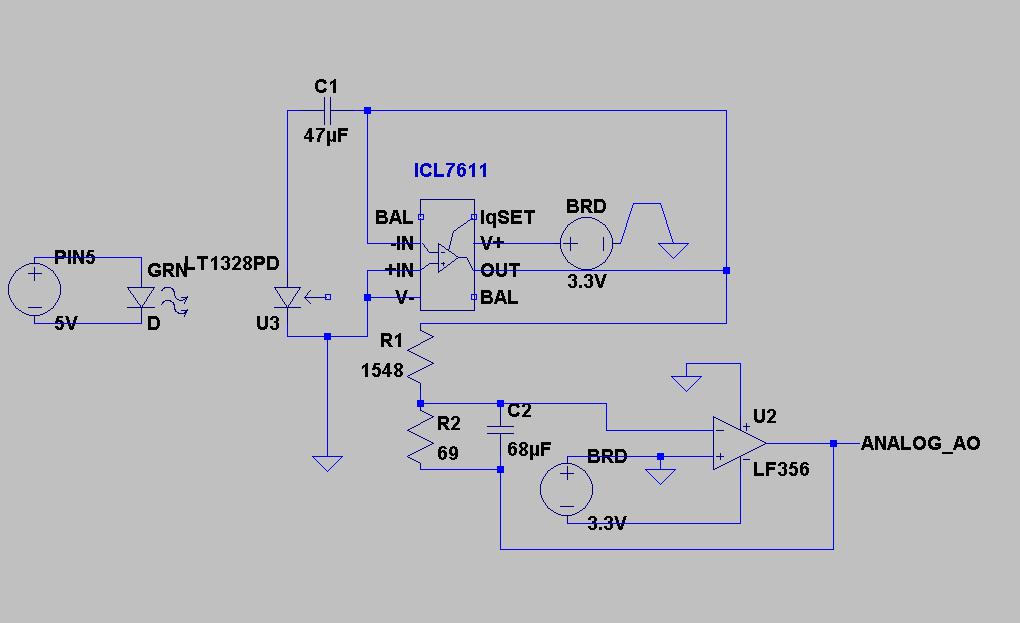

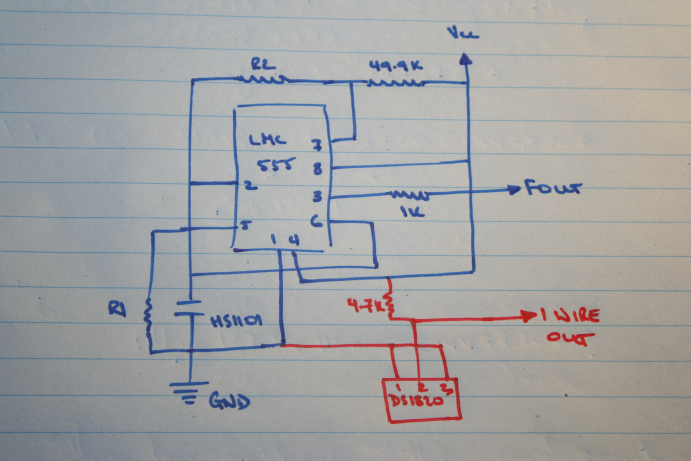

The project involves the design and implementation of a temperature and humidity sensor node, inspired by the FridgeControlWeb project. The circuit incorporates the HS1101 humidity sensor, which operates based on capacitance variation with humidity levels, and the Dallas 1820 temperature sensor, which communicates via a 1-Wire interface. The circuit is designed to minimize power consumption by powering down the HS1101 and associated components when not actively measuring, thereby reducing noise and potential interference.

The schematic features a CMOS version of the 555 timer, which is crucial for accurate readings; using an NMOS variant would result in erratic outputs. Resistor values R1 and R2 must be selected carefully to match the specifications for the LMC555, with R1 set at approximately 1.238 MΩ and R2 at around 562 kΩ to ensure accurate operation. The circuit also includes a microcontroller that manages the data collection and processing, with libraries included for network communication and temperature readings.

The system is programmed to perform measurement cycles at specified intervals, with a defined sleep period to conserve power. The web server setup is configured to handle requests and display the gathered data. The calibration process is ongoing, with the intention of aligning the sensor readings with actual environmental conditions, despite discrepancies noted in external weather data. The dual sensor system—one for indoor and one for outdoor readings—aims to facilitate effective control of the evaporative cooling system, ensuring optimal humidity levels within the home.This is just a quick post at the moment because the project isn`t done and I am distracted by other things. The thermostat for the central heater in my house became unreliable a week or two ago. My wife rang around and a new one from the manufacturer of the heater was going to be $450 AUD. So, it seemed obvious to make my own. I`ve just installed the 1. 0 of it, with the board layout and manufacture being done by Doug once again. The next sensor I wanted to add to my home was a set of hygrometers. Specifically I wanted an exterior one, and a matching interior one. This would be useful as we have evaporative cooling, and if the humidity level outside is already high, then it doesn`t make a lot of sense to put extra water into the air. Worse than that, it can also damage my books and make the house really clammy. So, adding some sensors was the first step in some form of alerting. I picked up two HS1101s from ebay quite cheaply (about $4 each IIRC). These devices are capacitors whose capacitance varies proportionally with relative humidity. You also need to provide a temperature at the sensor to correct the value, although the correction is pretty minor so I guess you could skip this if you really wanted to cut costs.

Given I have plenty of code for Dallas 1820s now, I just dropped one of those onto the board too. I just used the circuit from the data sheet for my design, with a few simple tweaks (like the DS1820). Here`s my surprisingly unprofessional circuit diagram: This gives us temperature on a 1-Wire pin, and an oscillator on another pin which relates to the current humidity.

You`ll notice that my circuit has some extra wires, that`s because I power down the 555 / HS1101 when I`m not taking a sample. I do this because Peter H. Anderson suggested that noise would be a problem otherwise. This circuit was actually quite hard to build and get working. There are a few reasons for that: The values for R1 and R2 vary depending on what model 555 you are using, and are crazily specific.

For the LMC555 that I used, R1 is 1238K and R2 is 562K. I got close to these values, but not exact and it did seem to affect accuracy. You must use a CMOS 555. That`s buried in a six word sentence in the middle of a page on the data sheet, and I didn`t notice it for a while. With a NMOS 555, you get effectively random numbers out of the circuit. Worse than that, CMOS 555s are actually a little hard to find, and I had to get mine from Farnell. I attempted to calibrate with the government weather data from the next suburb over. Unfortunately, as best as I can tell, that data is wrong. It claims that its currently as humid here as it is in Cairns in the wet season, which I deny. Calibration is an ongoing issue for me, although I have some ideas on how to progress there. It might also not matter, as I am building an identical sensor for inside the house and as long as they are both equally wrong I can still detect the "turn off the water to the evap" state that I want to.

// Temperature and humidity sensor node. Based on the FridgeControlWeb project of mine // as well as #include #include #include #include #include #include #include #include #include #include #define ONEWIRE 3 #define HS1101DATA 5 #define HS1101POWER 7 int count_transitions(int ms); // How long between measurement cycles #define SLEEP_SEC 10 OneWire oneWire(ONEWIRE); DallasTemperature sensors(&oneWire); unsigned long last_checked = 0, this_check = 0; // Web server setup #define MY 80 #define BUFFER_SIZE 550 #define ERROR_500 " 500 Error

Content-Type: text/html

The project involves the design and implementation of a temperature and humidity sensor node, inspired by the FridgeControlWeb project. The circuit incorporates the HS1101 humidity sensor, which operates based on capacitance variation with humidity levels, and the Dallas 1820 temperature sensor, which communicates via a 1-Wire interface. The circuit is designed to minimize power consumption by powering down the HS1101 and associated components when not actively measuring, thereby reducing noise and potential interference.

The schematic features a CMOS version of the 555 timer, which is crucial for accurate readings; using an NMOS variant would result in erratic outputs. Resistor values R1 and R2 must be selected carefully to match the specifications for the LMC555, with R1 set at approximately 1.238 MΩ and R2 at around 562 kΩ to ensure accurate operation. The circuit also includes a microcontroller that manages the data collection and processing, with libraries included for network communication and temperature readings.

The system is programmed to perform measurement cycles at specified intervals, with a defined sleep period to conserve power. The web server setup is configured to handle requests and display the gathered data. The calibration process is ongoing, with the intention of aligning the sensor readings with actual environmental conditions, despite discrepancies noted in external weather data. The dual sensor system—one for indoor and one for outdoor readings—aims to facilitate effective control of the evaporative cooling system, ensuring optimal humidity levels within the home.This is just a quick post at the moment because the project isn`t done and I am distracted by other things. The thermostat for the central heater in my house became unreliable a week or two ago. My wife rang around and a new one from the manufacturer of the heater was going to be $450 AUD. So, it seemed obvious to make my own. I`ve just installed the 1. 0 of it, with the board layout and manufacture being done by Doug once again. The next sensor I wanted to add to my home was a set of hygrometers. Specifically I wanted an exterior one, and a matching interior one. This would be useful as we have evaporative cooling, and if the humidity level outside is already high, then it doesn`t make a lot of sense to put extra water into the air. Worse than that, it can also damage my books and make the house really clammy. So, adding some sensors was the first step in some form of alerting. I picked up two HS1101s from ebay quite cheaply (about $4 each IIRC). These devices are capacitors whose capacitance varies proportionally with relative humidity. You also need to provide a temperature at the sensor to correct the value, although the correction is pretty minor so I guess you could skip this if you really wanted to cut costs.

Given I have plenty of code for Dallas 1820s now, I just dropped one of those onto the board too. I just used the circuit from the data sheet for my design, with a few simple tweaks (like the DS1820). Here`s my surprisingly unprofessional circuit diagram: This gives us temperature on a 1-Wire pin, and an oscillator on another pin which relates to the current humidity.

You`ll notice that my circuit has some extra wires, that`s because I power down the 555 / HS1101 when I`m not taking a sample. I do this because Peter H. Anderson suggested that noise would be a problem otherwise. This circuit was actually quite hard to build and get working. There are a few reasons for that: The values for R1 and R2 vary depending on what model 555 you are using, and are crazily specific.

For the LMC555 that I used, R1 is 1238K and R2 is 562K. I got close to these values, but not exact and it did seem to affect accuracy. You must use a CMOS 555. That`s buried in a six word sentence in the middle of a page on the data sheet, and I didn`t notice it for a while. With a NMOS 555, you get effectively random numbers out of the circuit. Worse than that, CMOS 555s are actually a little hard to find, and I had to get mine from Farnell. I attempted to calibrate with the government weather data from the next suburb over. Unfortunately, as best as I can tell, that data is wrong. It claims that its currently as humid here as it is in Cairns in the wet season, which I deny. Calibration is an ongoing issue for me, although I have some ideas on how to progress there. It might also not matter, as I am building an identical sensor for inside the house and as long as they are both equally wrong I can still detect the "turn off the water to the evap" state that I want to.

// Temperature and humidity sensor node. Based on the FridgeControlWeb project of mine // as well as #include