Assembling The Speed Controller

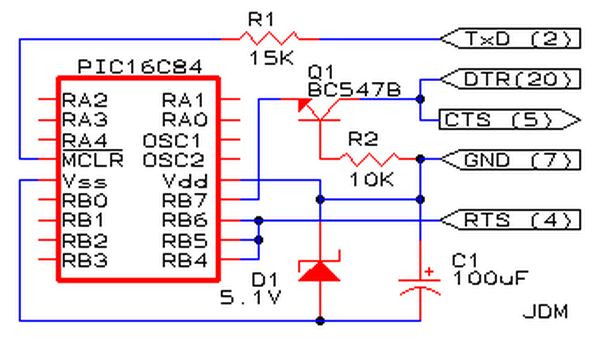

The 0.1µF monolithic capacitors will be marked '103 K' and the 15pF monolithic capacitors are marked '15 J'. It is crucial not to confuse the two. Do not remove either the MOSFETs or the integrated circuits from their protective static containers until just before use. Ideally, it is recommended to remain grounded while handling static-sensitive components. Generally, touching a grounded object before picking up a part suffices. Some items in the kit are polarized, meaning they must be installed with the correct orientation. The polarized components include tantalum capacitors (marked with a '+' on one lead), zener diodes (marked with a band on one end), one of the two resistor packs (marked with a dot on the end), and the integrated circuits. When installing the integrated circuit sockets, ensure the socket is oriented correctly (align the notch shape with the silkscreen) to assist in IC installation. The zener diodes and MOSFETs are heat-sensitive; prolonged contact with the soldering iron can damage them. It is advisable to count "one one thousand, two one thousand," etc., and if reaching "seven one thousand" without successfully creating a joint, stop. Wait 10 or 20 seconds for the part to cool before attempting again. This is particularly challenging in areas with wide traces, as the copper foil absorbs heat. The following steps will guide the assembly of the H-bridge board. Read through all steps first, then follow them in order during assembly. The assembly steps aim to build the board by "levels," meaning equal height components are installed simultaneously to prevent rocking and tilting on the work surface. Warning signs in some steps indicate that components must be installed in a specific orientation. Below is a picture of the unpopulated H-bridge board, bordered by a sequence of letters and numbers used to identify specific locations on the board using a notation of the form B, 3. This location indicates column B, row 3 on the board, while B, 1.5 indicates column B, between rows 1 and 2. The location B, 2-4 indicates a location in column B that spans rows 2, 3, and 4. Locate the H-bridge board, shown in figure 1, and install the two IC sockets (8 pin and 16 pin) and the 8 pin SIP socket. Note that the IC sockets have a notch that should align with the silkscreen notch. Turn the board over and solder them. A bit of masking tape can hold them in place while flipping the board. Locate the two zener diodes and install them at positions D, 3 and D, 4 in the image above. Ensure the orientation is correct, with the band facing to the left (away from the screw connectors). The Zeners may be marked 1N5242 or 1N4742. Install the 100K resistor pack at location C, 2-3, ensuring the orientation is correct; the pin one dot or line should face away from the 8 pin socket pointed down in the image above. Install the 1µF tantalum capacitor at location B, 1.5, ensuring the orientation is correct, with the plus-marked pin going into the hole marked '+'. The positive hole is the upper hole. Install the four MOSFETs at locations D, 1, D, 2, D, 3, and D, 4, and solder them carefully, ensuring the correct orientation of the MOSFETs.

The assembly of the H-bridge board involves careful attention to component orientation and handling techniques to avoid damage to sensitive parts. The polarized components, including tantalum capacitors and zener diodes, must be installed with their marked leads correctly aligned to ensure proper functionality. The integrated circuit sockets are designed to facilitate easy installation of the ICs, with notches that align with the silkscreen markings on the board.

When soldering, it is critical to avoid excessive heat exposure to heat-sensitive components like zener diodes and MOSFETs. Techniques such as timing the soldering duration and allowing components to cool can prevent damage. The assembly process is structured to minimize tilting of the board by installing components of equal height simultaneously, enhancing stability during assembly.

The use of notation for component placement simplifies the installation process, allowing for clear identification of locations on the board. Each component's position is designated with a combination of letters and numbers, aiding in precise placement. Following the outlined steps systematically ensures a successful assembly of the H-bridge board, leading to a functional circuit capable of driving motors or other loads efficiently. Proper assembly techniques, orientation checks, and careful soldering practices contribute to a reliable and robust electronic design.The. 01uf monolithic capacitors will be marked `103 K` and the 15pf monolithic capacitors are marked `15 J`. It is very important that you don`t confuse the two. DO NOT take either the MOSFETs or the Integrated circuits off their protective static containers until just before you use them.

Ideally, you should also keep yourself grounded whenever you handle static sensitive parts. In general it is sufficient to touch something that is grounded before you pick up a part. Some of the items in the kit are polarized. This means that they must be installed with the correct orientation. The parts that are polarized are the tantalum capacitors (marked with a + on one lead), the zener diodes (marked with a band on one end), one of the two resistor packs (marked with a dot on the end) and the integrated circuits. When you install the integrated circuit sockets be sure and orient the socket correctly (line up the notch shape with the silkscreen) so that it will guide you when installing the ICs.

The zener diodes and the MOSFETs are heat sensitive. This means that if you hold the soldering iron on them too long you can damage them. My reccommendation is that you count "one one thousand, two one thousand, etc" and if you get to "seven one thousand" and you haven`t successfully created the joint you stop. Wait 10 or 20 seconds for the part to cool and try again. This is particularly difficult on the areas where there are really wide traces because the copper foil absorbs the heat.

The following steps will take you through the assembly of the H-bridge board. Read through all of the steps first, then follow them in order when you assemble the board. The assembly steps attempt to build up the board by "levels", that is putting equal height components in at the same time so that the board doesn`t rock and tilt on your work surface while building it. On some of the steps you will see a warning sign, this sign indicates that the components being installed in that step must be installed in a specific orientation.

Below is a picture of the unpopulated H-bridge board. The board is bordered by a sequence of letters and numbers. The letters and numbers are used to identify specific locations on the board using a notation of the form B, 3. This location would be column B, row 3 on the board. Similarly the location B, 1. 5 would be column B, between rows 1 and 2. Whereas the location B, 2-4 indicates a location in column B that spans rows 2, 3, and 4. Locate the H-bridge board, its shown above in figure 1, and install the two IC sockets (8 pin and 16 pin) and the 8 pin SIP socket.

Note that the IC sockets have a notch that should line up with the silkscreen notch. Turn the board over and solder them. I find a bit of tape (masking tape) will hold them to the board while I`m flipping it over. Locate the two zener diodes and install them. They are located at positions D, 3 and D, 4 in the image above. Watch the orientation to make sure the band faces to the "left" (away from the screw connectors. ) Note that the Zeners may be marked 1N5242 or 1N4742 Install the 100K resistor pack at location C, 2-3. Watch the orientation of the resistor pack. The pin one "dot" or "line" indication should face away from the 8 pin socket which is pointed down in the image above.

Install the 1uF tantalum at location B, 1. 5. Watch the orientation of the tantalum, the plus marked pin goes in the hole marked "+". The positive hole is the upper hole. Install the four MOSFETs at locations D, 1, D, 2, D, 3, and D, 4, and solder them carefully. Watch the orientation of the MOSFETs. The tabs on the MOSFETs sho 🔗 External reference

The assembly of the H-bridge board involves careful attention to component orientation and handling techniques to avoid damage to sensitive parts. The polarized components, including tantalum capacitors and zener diodes, must be installed with their marked leads correctly aligned to ensure proper functionality. The integrated circuit sockets are designed to facilitate easy installation of the ICs, with notches that align with the silkscreen markings on the board.

When soldering, it is critical to avoid excessive heat exposure to heat-sensitive components like zener diodes and MOSFETs. Techniques such as timing the soldering duration and allowing components to cool can prevent damage. The assembly process is structured to minimize tilting of the board by installing components of equal height simultaneously, enhancing stability during assembly.

The use of notation for component placement simplifies the installation process, allowing for clear identification of locations on the board. Each component's position is designated with a combination of letters and numbers, aiding in precise placement. Following the outlined steps systematically ensures a successful assembly of the H-bridge board, leading to a functional circuit capable of driving motors or other loads efficiently. Proper assembly techniques, orientation checks, and careful soldering practices contribute to a reliable and robust electronic design.The. 01uf monolithic capacitors will be marked `103 K` and the 15pf monolithic capacitors are marked `15 J`. It is very important that you don`t confuse the two. DO NOT take either the MOSFETs or the Integrated circuits off their protective static containers until just before you use them.

Ideally, you should also keep yourself grounded whenever you handle static sensitive parts. In general it is sufficient to touch something that is grounded before you pick up a part. Some of the items in the kit are polarized. This means that they must be installed with the correct orientation. The parts that are polarized are the tantalum capacitors (marked with a + on one lead), the zener diodes (marked with a band on one end), one of the two resistor packs (marked with a dot on the end) and the integrated circuits. When you install the integrated circuit sockets be sure and orient the socket correctly (line up the notch shape with the silkscreen) so that it will guide you when installing the ICs.

The zener diodes and the MOSFETs are heat sensitive. This means that if you hold the soldering iron on them too long you can damage them. My reccommendation is that you count "one one thousand, two one thousand, etc" and if you get to "seven one thousand" and you haven`t successfully created the joint you stop. Wait 10 or 20 seconds for the part to cool and try again. This is particularly difficult on the areas where there are really wide traces because the copper foil absorbs the heat.

The following steps will take you through the assembly of the H-bridge board. Read through all of the steps first, then follow them in order when you assemble the board. The assembly steps attempt to build up the board by "levels", that is putting equal height components in at the same time so that the board doesn`t rock and tilt on your work surface while building it. On some of the steps you will see a warning sign, this sign indicates that the components being installed in that step must be installed in a specific orientation.

Below is a picture of the unpopulated H-bridge board. The board is bordered by a sequence of letters and numbers. The letters and numbers are used to identify specific locations on the board using a notation of the form B, 3. This location would be column B, row 3 on the board. Similarly the location B, 1. 5 would be column B, between rows 1 and 2. Whereas the location B, 2-4 indicates a location in column B that spans rows 2, 3, and 4. Locate the H-bridge board, its shown above in figure 1, and install the two IC sockets (8 pin and 16 pin) and the 8 pin SIP socket.

Note that the IC sockets have a notch that should line up with the silkscreen notch. Turn the board over and solder them. I find a bit of tape (masking tape) will hold them to the board while I`m flipping it over. Locate the two zener diodes and install them. They are located at positions D, 3 and D, 4 in the image above. Watch the orientation to make sure the band faces to the "left" (away from the screw connectors. ) Note that the Zeners may be marked 1N5242 or 1N4742 Install the 100K resistor pack at location C, 2-3. Watch the orientation of the resistor pack. The pin one "dot" or "line" indication should face away from the 8 pin socket which is pointed down in the image above.

Install the 1uF tantalum at location B, 1. 5. Watch the orientation of the tantalum, the plus marked pin goes in the hole marked "+". The positive hole is the upper hole. Install the four MOSFETs at locations D, 1, D, 2, D, 3, and D, 4, and solder them carefully. Watch the orientation of the MOSFETs. The tabs on the MOSFETs sho 🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713