AVR Projects

.jpg)

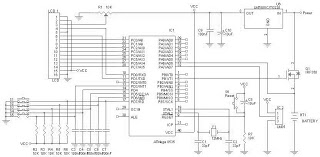

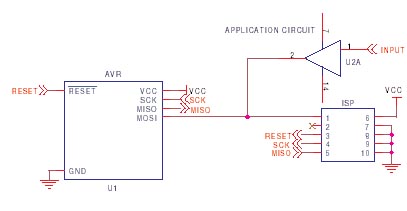

This project is a combined temperature and humidity meter. It is an enhancement of a previous PIC-based humidity meter and PIC and AVR thermometers. The design utilizes an ATmega164 microcontroller, which offers ample input/output ports and memory. The humidity sensor employed is the HS1101, manufactured by Parallax (part number 27920) and available from Digikey (27920-ND) for approximately US$10. The humidity sensor circuit is identical to that of the earlier project. A construction error in the previous design caused erratic operation, as the HS1101 sensor needed to be positioned as close as possible to the LMC555 timer. A 4-inch wire connection to the circuit board introduced sensitivity to surrounding noise. In this iteration, the sensor board is located at the top of the enclosure, allowing the HS1101 to connect directly to the circuit. This top board houses the LMC555 circuit and the power supply regulator. A 6-conductor cable runs to the lower board, which contains the CPU, while the middle board features the LCD display and two switches that secure the board in place. A 26-conductor ribbon cable connects to the CPU board located just below. Due to the low power consumption of the LCD, the unit is battery-operated, with provisions for an external power supply, marking a significant improvement over previous versions. The battery and holder are positioned at the bottom of the case. Power leads connect to the on/off switch (SW1) and subsequently to the sensor board regulator, supplying regulated power to the CPU board. The LCD display lacks a controller or backlight, and its operation can be cumbersome due to the requirement of 24 connections to the CPU, necessitating the large ribbon cable. Each segment of the display must be driven individually by the program. Despite being inexpensive (<C$2) and energy-efficient, the absence of a backlight is a noted drawback. It is important to mention that the display is a static LCD, which typically requires an AC signal to drive the segments. However, this implementation does not utilize that method, as the Lumex display retains contrast for a period after power-up, which is manageable since the unit is not intended for prolonged use. Upon powering on, the battery voltage is sampled through resistors R5 and R6 and ADC0. The battery voltage is displayed for 2 to 3 seconds before switching to show either temperature or humidity, depending on the setting of switch SW2. Additional enhancements include the option to select Celsius or Fahrenheit (JP1) and the capability to display negative temperatures. The temperature sensor connects to ADC7 and utilizes the internal 1.1V reference voltage. A digital median filter is applied to stabilize the temperature readings. The humidity circuit generates a square wave signal, which is connected to timer T1. Timer0 is configured to provide one-second intervals, during which the T1 count is read and reset. An interpolation routine is employed to convert the measured frequency into humidity values.

The combined temperature and humidity meter circuit integrates several key components and design considerations to achieve accurate measurements and reliable performance. The ATmega164 microcontroller serves as the central processing unit, managing data acquisition from the sensors and controlling the display output. The HS1101 humidity sensor operates on a principle that requires careful placement to minimize noise interference, which has been addressed by positioning it in close proximity to the LMC555 timer.

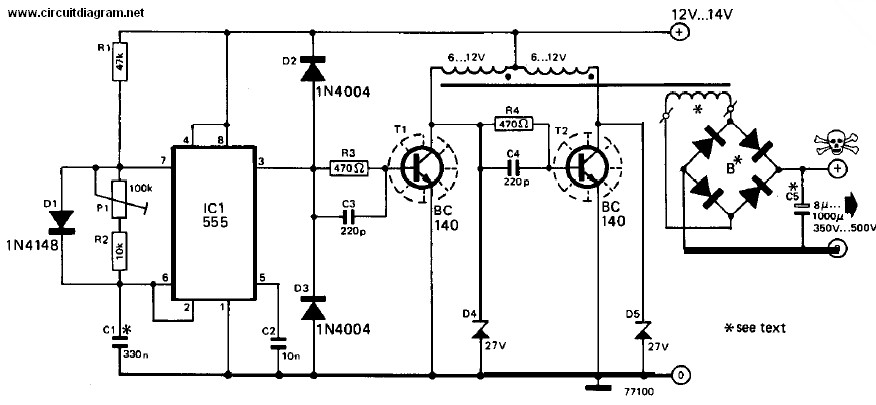

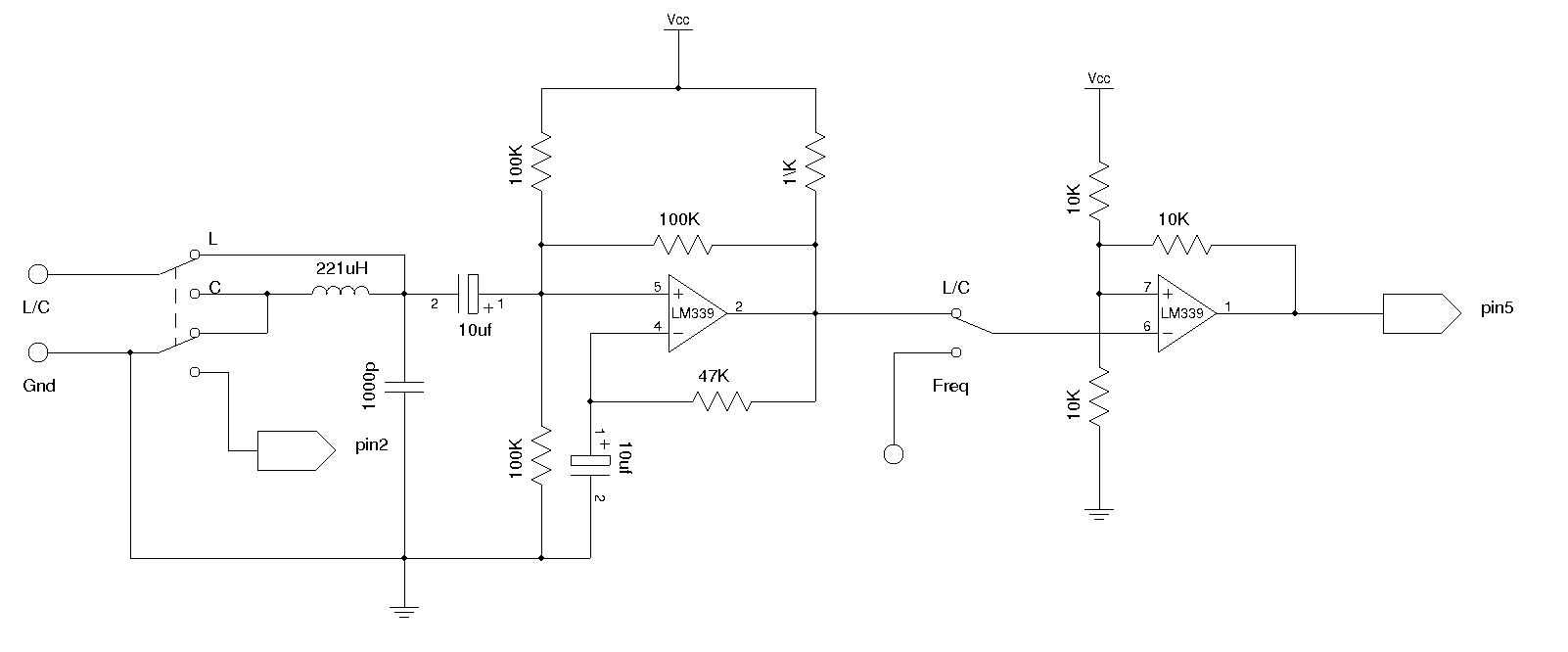

The LMC555 timer is configured in a stable mode to generate a square wave output, which is crucial for the humidity measurement process. The output frequency of the HS1101 is directly related to the humidity level, allowing the microcontroller to calculate humidity by measuring the frequency of the square wave signal. Timer0 is programmed to generate regular intervals, facilitating consistent readings and ensuring that the microcontroller can process data without delays.

The LCD display, although lacking a backlight, is driven directly by the microcontroller through a large number of connections. This design choice reflects a trade-off between cost and functionality, as the static LCD provides sufficient visibility for short usage periods. The absence of a backlight is mitigated by the display's ability to maintain contrast temporarily after power-up, making it suitable for brief readings.

Power management is another critical aspect of the design. The unit operates on batteries, with a power supply regulator ensuring stable voltage to the microcontroller and sensors. The inclusion of an external power supply option enhances versatility, allowing the device to be powered continuously when necessary.

In summary, this combined temperature and humidity meter project demonstrates an effective integration of microcontroller technology, sensor design, and power management strategies to deliver a functional and compact measuring instrument. The enhancements made over previous designs address earlier challenges and improve overall usability, making it a valuable tool for environmental monitoring applications.This project is a combined temperature and humiditymeter. It is an improvement on my PIC-based humidity meter and my PIC and AVR thermometers. I use an ATmega164, which as lots of I/O and memory. The humidity sensor is a HS1101, made by Parallax (p/n 27920) and available from Digikey (27920-ND) for around US$10. The circuit for the humidity meter sensor is identical to the earlier project. I had made a mistake in construction, which resulted in erratic operation. The problem is that the HS1101 must be physically as close to the LMC555 as possible. I had runa 4-inch wire to the circuit board, and the unit became sensitive to noise picked up from the surroundings. In this version, I placed the sensor board at the top of the case, where the HS1101 can plug right in to the circuit.

and the HS1101 humidity sensor. The board at the top contains the LMC555 circuit and the power supply regulator. A 6 conductor cable goes the the lower board, which contains the CPU. The middle board has the LCD display and 2 switches. The switches hold the board in place. There is a 26 conductor ribbon cable to the CPU board just below. Since the LCD uses little power, the unit is battery operated (with provision for an external power supply), another big improvement over the older projects. The battery and holder are at the bottom of the case. The power leads go to the on/off switch (SW1) and then to the sensor board regulator, and regulated power goes to the CPU board.

with no controller or backlight. I must admit that this LCD display is a pain to use. You need 24 connections to the CPU (hence the large ribbon cable in the photo), and the program must drive each segment to make up the display. However itis cheap (

A very good write-up on the subject can be found here. However I did not implement this, as I find that the Lumex display maintains its contrast for some time after power-up. I never leave the unit on for more than a few seconds at a time, so this is not a problem for me. When you switch the unit on, the battery voltage is sampled via R5 and R6 and ADC0. For 2 or 3 seconds, the battery voltage is displayed. Then the display changes to temperature or humidity, depending on the setting of SW2. Other improvements are the choice of Celsius or Fahrenheit (JP1), and the ability to display negative temperatures.

The temperature sensor is connected to ADC7 and uses the internal 1. 1V Vref. A digital median filter is used to smooth out the temperature display. The humidity circuit generates a squarewave which is connected to T1. Timer0 is programmed to give 1 second intervals, where the T1 count is read and reset. An interpolating routine is used to get humidity from the measured frequency. 🔗 External reference

The combined temperature and humidity meter circuit integrates several key components and design considerations to achieve accurate measurements and reliable performance. The ATmega164 microcontroller serves as the central processing unit, managing data acquisition from the sensors and controlling the display output. The HS1101 humidity sensor operates on a principle that requires careful placement to minimize noise interference, which has been addressed by positioning it in close proximity to the LMC555 timer.

The LMC555 timer is configured in a stable mode to generate a square wave output, which is crucial for the humidity measurement process. The output frequency of the HS1101 is directly related to the humidity level, allowing the microcontroller to calculate humidity by measuring the frequency of the square wave signal. Timer0 is programmed to generate regular intervals, facilitating consistent readings and ensuring that the microcontroller can process data without delays.

The LCD display, although lacking a backlight, is driven directly by the microcontroller through a large number of connections. This design choice reflects a trade-off between cost and functionality, as the static LCD provides sufficient visibility for short usage periods. The absence of a backlight is mitigated by the display's ability to maintain contrast temporarily after power-up, making it suitable for brief readings.

Power management is another critical aspect of the design. The unit operates on batteries, with a power supply regulator ensuring stable voltage to the microcontroller and sensors. The inclusion of an external power supply option enhances versatility, allowing the device to be powered continuously when necessary.

In summary, this combined temperature and humidity meter project demonstrates an effective integration of microcontroller technology, sensor design, and power management strategies to deliver a functional and compact measuring instrument. The enhancements made over previous designs address earlier challenges and improve overall usability, making it a valuable tool for environmental monitoring applications.This project is a combined temperature and humiditymeter. It is an improvement on my PIC-based humidity meter and my PIC and AVR thermometers. I use an ATmega164, which as lots of I/O and memory. The humidity sensor is a HS1101, made by Parallax (p/n 27920) and available from Digikey (27920-ND) for around US$10. The circuit for the humidity meter sensor is identical to the earlier project. I had made a mistake in construction, which resulted in erratic operation. The problem is that the HS1101 must be physically as close to the LMC555 as possible. I had runa 4-inch wire to the circuit board, and the unit became sensitive to noise picked up from the surroundings. In this version, I placed the sensor board at the top of the case, where the HS1101 can plug right in to the circuit.

and the HS1101 humidity sensor. The board at the top contains the LMC555 circuit and the power supply regulator. A 6 conductor cable goes the the lower board, which contains the CPU. The middle board has the LCD display and 2 switches. The switches hold the board in place. There is a 26 conductor ribbon cable to the CPU board just below. Since the LCD uses little power, the unit is battery operated (with provision for an external power supply), another big improvement over the older projects. The battery and holder are at the bottom of the case. The power leads go to the on/off switch (SW1) and then to the sensor board regulator, and regulated power goes to the CPU board.

with no controller or backlight. I must admit that this LCD display is a pain to use. You need 24 connections to the CPU (hence the large ribbon cable in the photo), and the program must drive each segment to make up the display. However itis cheap (

A very good write-up on the subject can be found here. However I did not implement this, as I find that the Lumex display maintains its contrast for some time after power-up. I never leave the unit on for more than a few seconds at a time, so this is not a problem for me. When you switch the unit on, the battery voltage is sampled via R5 and R6 and ADC0. For 2 or 3 seconds, the battery voltage is displayed. Then the display changes to temperature or humidity, depending on the setting of SW2. Other improvements are the choice of Celsius or Fahrenheit (JP1), and the ability to display negative temperatures.

The temperature sensor is connected to ADC7 and uses the internal 1. 1V Vref. A digital median filter is used to smooth out the temperature display. The humidity circuit generates a squarewave which is connected to T1. Timer0 is programmed to give 1 second intervals, where the T1 count is read and reset. An interpolating routine is used to get humidity from the measured frequency. 🔗 External reference