battery tender for the school server

The ideas presented here explore various methods for controlling and monitoring the charging of lead-acid storage batteries. To ensure that the benefits of digital technology impact education in developing regions, reliable access during school hours is essential. The O-1.75 device has a battery life exceeding four hours, addressing part of the problem. However, the School Server, which serves as a gateway to the internet and local content, must also remain operational during rolling blackouts. Therefore, battery backup for the School Server is crucial, and lead-acid technology remains the most cost-effective solution. It is advisable to allow the battery to discharge to a point where more than 50% of its energy has been used. Complete discharge may lead to failure within a few days of inactivity. For the least expensive flooded lead-acid batteries, extending lifespan can be achieved through monthly overcharging for one to two hours, known as an equalizing charge. Utilizing pulse width modulation output, the system can regulate the charging current applied to the battery. This setup can harness energy from a 100-watt solar panel or a 30-watt laptop power brick, providing an optimal charging profile to maximize battery life. The Arduino can gather data regarding electrical current flowing into and out of the battery, displaying the current charge state and the apparent maximum capacity on an LCD panel. As batteries age, their output voltage declines more rapidly as energy is utilized. When connected to the School Server, the Arduino can log historical data on battery health and functionality, which can be transmitted to an internet server for display on any connected browser. The Arduino features six inputs that measure voltages from 0 to 5 volts, dividing this range into 1024 steps. Various circuits have been explored to convert current and voltage into this 0-5 volt range. Hall effect transducers were initially considered due to their suitability for outputting in the 0-5 volt range; however, they are relatively expensive and fragile. Commercially available shunt resistors were also evaluated, but a 0.001 ohm, 100 Amp capable resistor was bulky and costly. A DIY approach to creating shunts was referenced, and a 1-watt, 0.05 ohm resistor from Digi-Key was considered for its affordability. After experimenting with costly op-amps and breadboard circuits that oscillated, a functional and inexpensive breadboard was assembled. This allowed for the development of an Arduino program to translate voltages into currents and output them on an LCD shield. Scott Ananian from OLPC Boston designed an Arduino board for the XO, which was costed around $5 in quantities of 100 at Digi-Key. He documented the circuit board design using Eagle, prompting an attempt to replicate the process. The two attachments illustrate the circuit and the ongoing circuit board layout. Further steps include adjusting design rules in Eagle for routing and trace generation, followed by acquiring PC stock and employing the Xerox resist method for etching the board. A battery salesman suggested incorporating a desulfating function for school servers, as all lead-acid batteries are prone to sulfation, which involves the buildup of lead sulfate crystals.

The described circuit focuses on the effective management of lead-acid battery charging and monitoring, which is essential for ensuring continuous power supply to educational technology in environments prone to power interruptions. The system utilizes an Arduino microcontroller interfaced with various sensors and an LCD display to provide real-time data on battery performance, including charge state and capacity.

The pulse width modulation (PWM) technique is employed to regulate the charging current, optimizing the charging process when using renewable energy sources like solar panels. This approach not only enhances battery life but also promotes sustainability by utilizing available solar energy. The integration of historical logging capabilities allows for the assessment of battery health over time, facilitating preventive maintenance and timely interventions.

The choice of components is critical for the reliability and cost-effectiveness of the system. The use of shunt resistors for current measurement, along with the exploration of DIY options, demonstrates a commitment to minimizing costs while maintaining functionality. The design considerations involving the Eagle CAD software illustrate the importance of precise circuit layout in ensuring efficient operation and manufacturability.

Incorporating a desulfating function addresses a common issue faced by lead-acid batteries, enhancing their longevity and performance. This additional feature could be automated within the Arduino's programming, further improving the system's effectiveness in maintaining battery health.

Overall, the circuit design represents a comprehensive approach to battery management, focusing on sustainability, reliability, and cost-effectiveness, thereby supporting educational initiatives in developing regions.The ideas presented here are an exploration of the different possibilities for controlling and monitoring the charging of lead-acid storage batteries) If the benefits of digital technology are to impact education in the developing world, it needs to be reliably available during the school hours. Now that the X O-1. 75 has a battery life of 4+ hours, that part of the problem seems solved. But the School Server, providing a gateway to the internet, local content, collaboration, also needs to be available, even when the rolling blackouts occur. Battery backup for the School Server is essential, and lead-acid technology is still the most cost effective solution.

Let it discharge to the point where you have used up more than 50% of the energy it has available. Let it discharge all the way, and it may die in a few days just sitting. For the cheapest flooded lead acid batteries, additional lifespan can be achieved if they are overcharged every month, for a period of an hour or two (called an equalizing charge). Using its pulse width modulation output, it can control the charging current applied to the battery. In this capacity, it can take energy from a 100 watt solar panel, or from a 30 watt laptop power brick, and provide the optimum charging profile for maximum battery life.

The arduino can accumulate information about electrical current into and out of the battery, and display on the lcd panel the current charge state, and the apparent maximum capacity of the battery (as a battery ages, its output voltage declines more rapidly as energy is removed). Connected to the School Server, the arduino can create a log to accumulate historical data about the health and function of the battery.

This data can be transmitted to a server on the internet for display to any internet connected browser. The arduino has 6 inputs that measure 0-5 volts, and divide that range of voltages into 1024 voltage steps.

I`ve played with a number of circuits that are trying to change current and voltage into this 0-5 volt range. I`ve experimented with different means of measuring battery charge and discharge current. The hall effect transducers seemed to me a good choice because they can be configured to have their outputs in the 0 5 volt range.

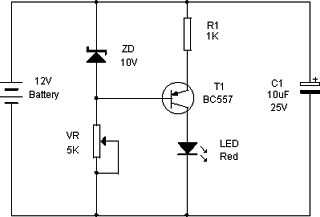

But they are expensive, $17-27, as as I learned the hard way, from some manufacturers, very fragile. Next, I tried commercially available shunt resistors. The. 001 ohm 100Amp capable one was almost $20 and big and bulky. The 100 A seems overkill. I came across a DIY reference to making your own shunts at, and more recently I`ve been considering a 1 watt. 05 ohm resistor from digikey for less than a dollar. Skipping over a long description of the more expensive op-amps, and the breadboard circuits which went into oscillation, I finally put together a breadboard that was inexpensive, and worked well enough so that I could focus on writing the arduino program to translate the voltages to currents, and spit them out on a lcd shield piggybacked on the arduino.

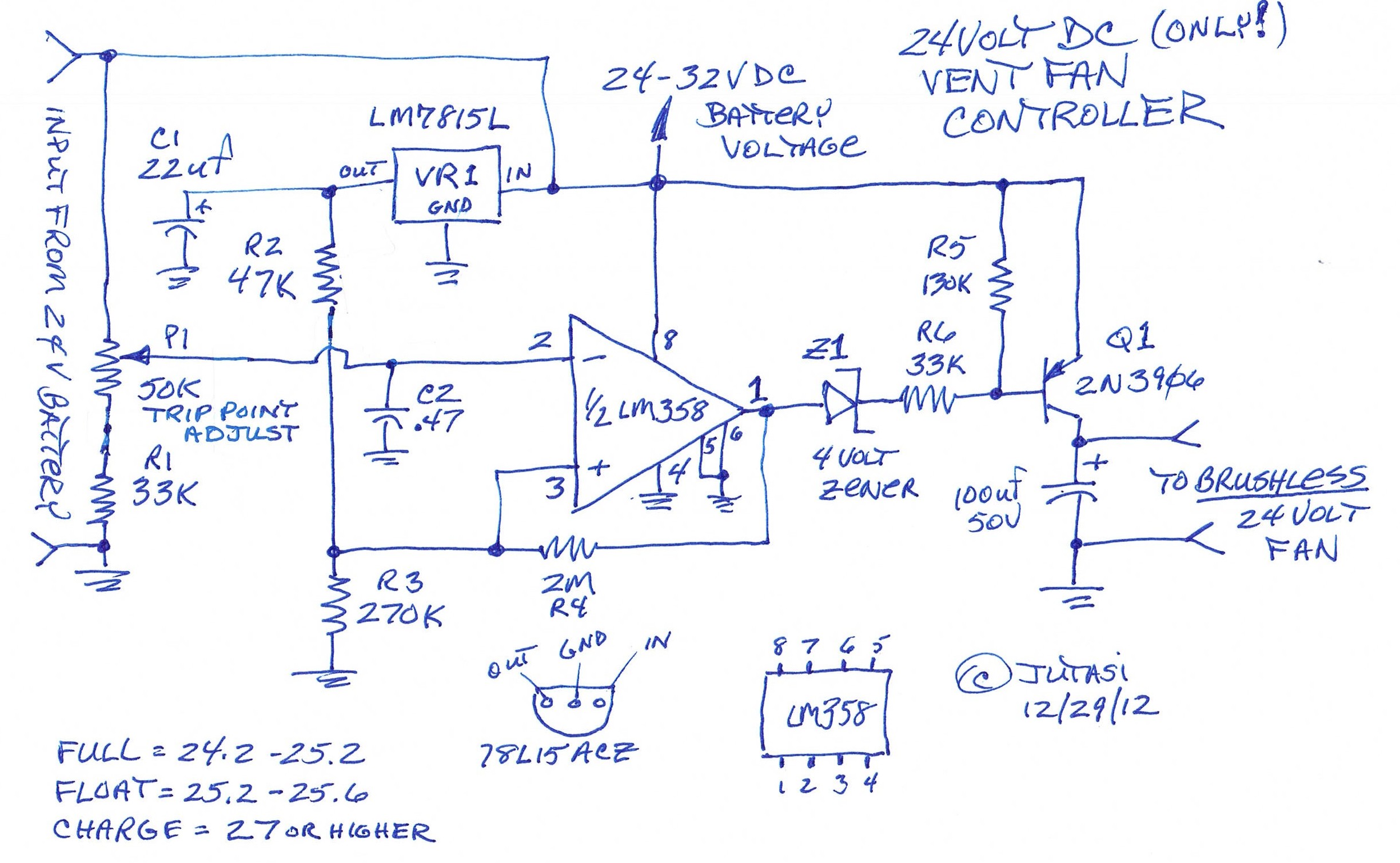

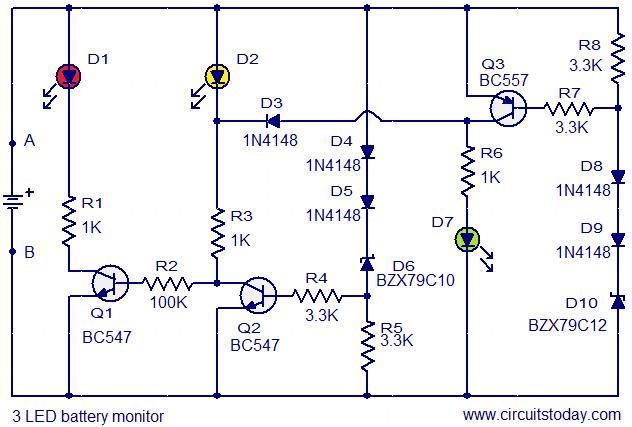

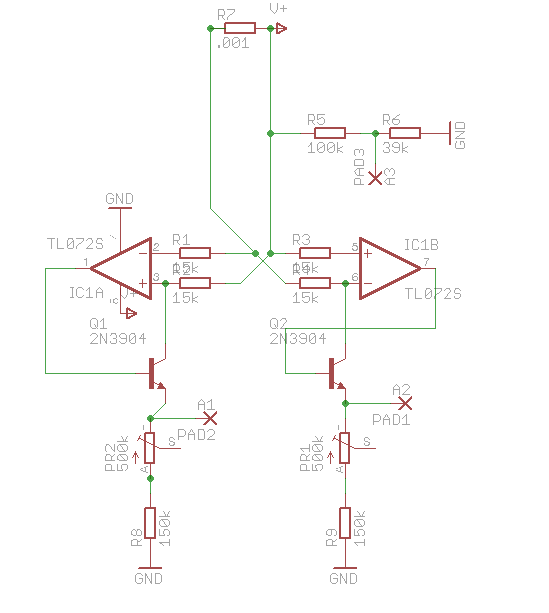

Scott Ananian, from OLPC Boston, designed an arduino board for the XO that he costed out in 100 quantities at digikey in the $5 neighborhood. He documented his work designing the circuit board, using Eagle, and I just had to try my hand. Eagle is really fun. The two attachments show the circuit and the in-process circuit board layout. But that`s as far as I have gotten. Next I need to get, and tweak the design rules that the Eagle program will use in its routing and trace generation phase.

Then I was hoping to get some PC stock, and use the Xerox resist method of etching the board. It was a battery salesman I met that suggested that school servers should have a desulfating function. The best internet description of the process I have found is at. The idea is basically that all lead acid batteries are subject to a process, called sulfation, which is the build up of

🔗 External reference

The described circuit focuses on the effective management of lead-acid battery charging and monitoring, which is essential for ensuring continuous power supply to educational technology in environments prone to power interruptions. The system utilizes an Arduino microcontroller interfaced with various sensors and an LCD display to provide real-time data on battery performance, including charge state and capacity.

The pulse width modulation (PWM) technique is employed to regulate the charging current, optimizing the charging process when using renewable energy sources like solar panels. This approach not only enhances battery life but also promotes sustainability by utilizing available solar energy. The integration of historical logging capabilities allows for the assessment of battery health over time, facilitating preventive maintenance and timely interventions.

The choice of components is critical for the reliability and cost-effectiveness of the system. The use of shunt resistors for current measurement, along with the exploration of DIY options, demonstrates a commitment to minimizing costs while maintaining functionality. The design considerations involving the Eagle CAD software illustrate the importance of precise circuit layout in ensuring efficient operation and manufacturability.

Incorporating a desulfating function addresses a common issue faced by lead-acid batteries, enhancing their longevity and performance. This additional feature could be automated within the Arduino's programming, further improving the system's effectiveness in maintaining battery health.

Overall, the circuit design represents a comprehensive approach to battery management, focusing on sustainability, reliability, and cost-effectiveness, thereby supporting educational initiatives in developing regions.The ideas presented here are an exploration of the different possibilities for controlling and monitoring the charging of lead-acid storage batteries) If the benefits of digital technology are to impact education in the developing world, it needs to be reliably available during the school hours. Now that the X O-1. 75 has a battery life of 4+ hours, that part of the problem seems solved. But the School Server, providing a gateway to the internet, local content, collaboration, also needs to be available, even when the rolling blackouts occur. Battery backup for the School Server is essential, and lead-acid technology is still the most cost effective solution.

Let it discharge to the point where you have used up more than 50% of the energy it has available. Let it discharge all the way, and it may die in a few days just sitting. For the cheapest flooded lead acid batteries, additional lifespan can be achieved if they are overcharged every month, for a period of an hour or two (called an equalizing charge). Using its pulse width modulation output, it can control the charging current applied to the battery. In this capacity, it can take energy from a 100 watt solar panel, or from a 30 watt laptop power brick, and provide the optimum charging profile for maximum battery life.

The arduino can accumulate information about electrical current into and out of the battery, and display on the lcd panel the current charge state, and the apparent maximum capacity of the battery (as a battery ages, its output voltage declines more rapidly as energy is removed). Connected to the School Server, the arduino can create a log to accumulate historical data about the health and function of the battery.

This data can be transmitted to a server on the internet for display to any internet connected browser. The arduino has 6 inputs that measure 0-5 volts, and divide that range of voltages into 1024 voltage steps.

I`ve played with a number of circuits that are trying to change current and voltage into this 0-5 volt range. I`ve experimented with different means of measuring battery charge and discharge current. The hall effect transducers seemed to me a good choice because they can be configured to have their outputs in the 0 5 volt range.

But they are expensive, $17-27, as as I learned the hard way, from some manufacturers, very fragile. Next, I tried commercially available shunt resistors. The. 001 ohm 100Amp capable one was almost $20 and big and bulky. The 100 A seems overkill. I came across a DIY reference to making your own shunts at, and more recently I`ve been considering a 1 watt. 05 ohm resistor from digikey for less than a dollar. Skipping over a long description of the more expensive op-amps, and the breadboard circuits which went into oscillation, I finally put together a breadboard that was inexpensive, and worked well enough so that I could focus on writing the arduino program to translate the voltages to currents, and spit them out on a lcd shield piggybacked on the arduino.

Scott Ananian, from OLPC Boston, designed an arduino board for the XO that he costed out in 100 quantities at digikey in the $5 neighborhood. He documented his work designing the circuit board, using Eagle, and I just had to try my hand. Eagle is really fun. The two attachments show the circuit and the in-process circuit board layout. But that`s as far as I have gotten. Next I need to get, and tweak the design rules that the Eagle program will use in its routing and trace generation phase.

Then I was hoping to get some PC stock, and use the Xerox resist method of etching the board. It was a battery salesman I met that suggested that school servers should have a desulfating function. The best internet description of the process I have found is at. The idea is basically that all lead acid batteries are subject to a process, called sulfation, which is the build up of

🔗 External reference