Buck-Based LED Drivers

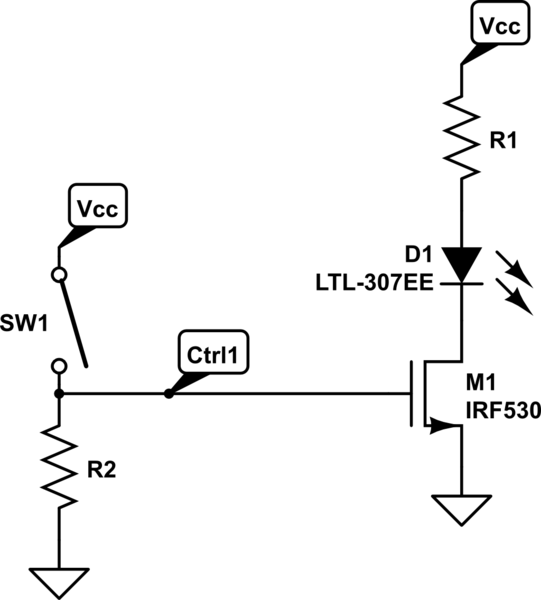

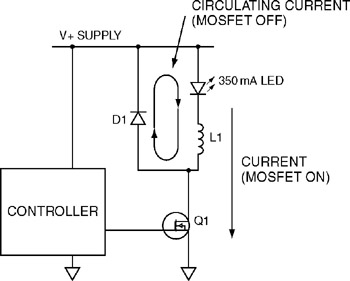

The first switching LED driver to be examined is the buck converter. The buck converter is the simplest type of switching driver and serves as a step-down converter for applications where the load voltage is typically no more than approximately 85% of the supply voltage. This 85% limitation arises from switching delays within the control system. In a buck converter circuit, a power MOSFET is commonly employed to switch the supply voltage across an inductor and a series-connected LED load. The inductor functions to store energy when the MOSFET is activated; this stored energy is subsequently utilized to supply current to the LED when the MOSFET is deactivated. A diode situated across the LED and inductor circuit provides a return path for the current during the MOSFET's off period. Buck converters represent a compelling option for LED drivers in both offline and low-voltage applications, as they can deliver a consistent LED current with very high efficiencies. A peak-current-controlled buck converter can maintain reasonable LED current variations across a broad spectrum of input and LED voltages without requiring extensive feedback control design efforts. Furthermore, these converters can be engineered to achieve efficiencies exceeding 90%, making buck-based drivers an appealing choice for driving high-brightness LEDs.

The buck converter circuit operates based on the principle of energy storage and release through inductive components. When the power MOSFET is turned on, current flows through the inductor, causing it to store energy in the form of a magnetic field. The LED load, connected in series with the inductor, experiences a voltage drop that corresponds to the input supply voltage minus the voltage drop across the MOSFET. When the MOSFET is switched off, the inductor releases its stored energy, maintaining the current flow through the LED by utilizing the diode as a path for the current. This process ensures that the LED receives a steady current, which is crucial for its optimal performance and longevity.

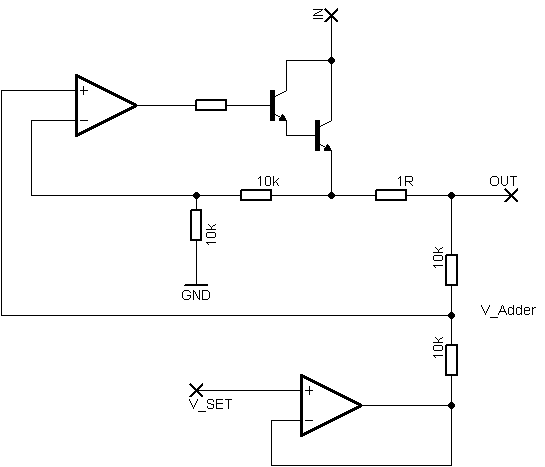

To enhance the performance of the buck converter, various control strategies can be implemented. One common approach is to use peak current mode control, which regulates the current flowing through the inductor by monitoring its peak value. This method provides inherent protection against overcurrent conditions and allows for stable operation across varying input and output conditions. Additionally, the design can incorporate feedback mechanisms to adjust the duty cycle of the MOSFET, ensuring that the output current remains constant despite fluctuations in the supply voltage or load conditions.

The efficiency of buck converters is primarily influenced by several factors, including the on-resistance of the MOSFET, the forward voltage drop of the diode, and the quality of the inductor. Selecting components with low losses and optimizing the layout to minimize parasitic inductances and capacitances can significantly enhance overall efficiency. In high-brightness LED applications, where thermal management is also a concern, maintaining high efficiency is crucial to prevent overheating and ensure reliable operation.

In summary, the buck converter is a versatile and efficient solution for driving LEDs, particularly in applications requiring a stable output current with minimal power loss. Its simplicity, coupled with the ability to achieve high efficiency, makes it a preferred choice among engineers designing LED driver circuits.The first switching LED driver that we will study is the buck converter. The buck converter is the simplest of the switching drivers, and is a step-down converter for applications where the load voltage is never more than about 85% of the supply voltage. The limit of about 85% is due to switching delays in the control system. In a buck converter c ircuit, a power MOSFET is usually used to switch the supply voltage across an inductor and LED load connected in series. The inductor is used to store energy when the MOSFET is turned on; this energy is then used to provide current for the LED when the MOSFET is turned off.

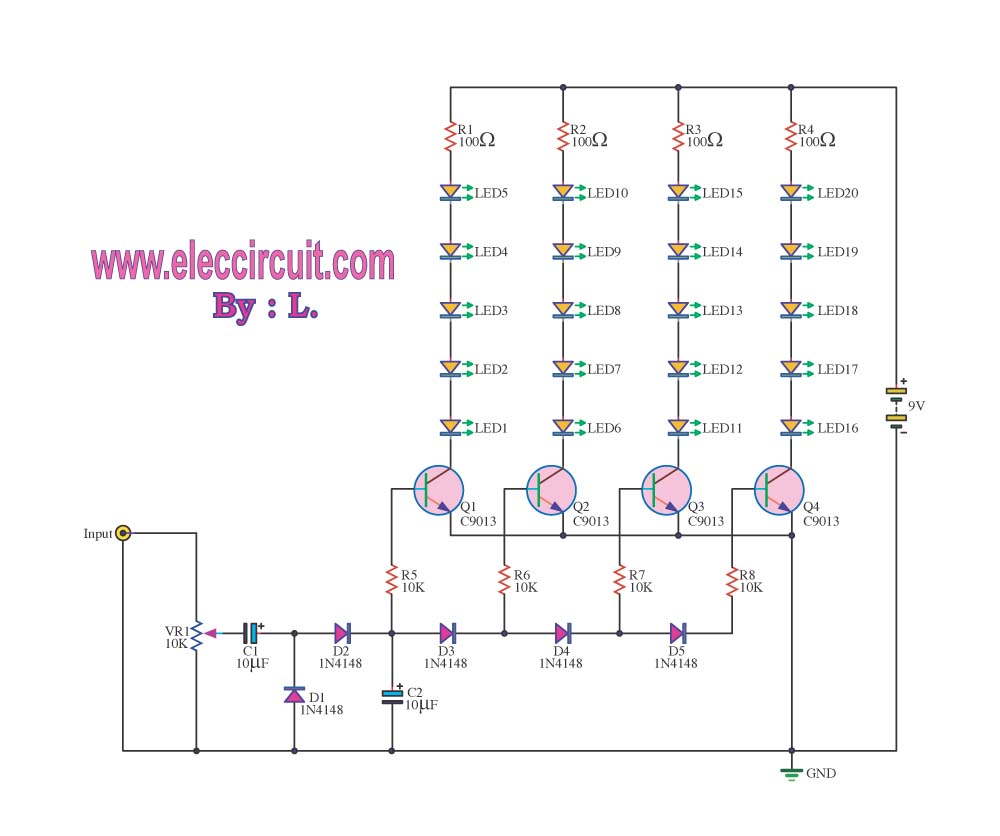

A diode across the LED and inductor circuit provides a return path for the current during the MOSFET off time. A simple schematic is shown in Figure 5. 1. Buck converters are an attractive choice for LED drivers in offline and in low voltage applications as they can produce a constant LED current at very high efficiencies.

A peak-current-controlled buck converter can give reasonable LED current variation over a wide range of input and LED voltages and needs no design effort in feedback control design. Coupled with the fact that these converters can be designed to operate at above 90% efficiencies, the buck-based driver becomes an attractive solution to drive high brightness LEDs.

🔗 External reference

The buck converter circuit operates based on the principle of energy storage and release through inductive components. When the power MOSFET is turned on, current flows through the inductor, causing it to store energy in the form of a magnetic field. The LED load, connected in series with the inductor, experiences a voltage drop that corresponds to the input supply voltage minus the voltage drop across the MOSFET. When the MOSFET is switched off, the inductor releases its stored energy, maintaining the current flow through the LED by utilizing the diode as a path for the current. This process ensures that the LED receives a steady current, which is crucial for its optimal performance and longevity.

To enhance the performance of the buck converter, various control strategies can be implemented. One common approach is to use peak current mode control, which regulates the current flowing through the inductor by monitoring its peak value. This method provides inherent protection against overcurrent conditions and allows for stable operation across varying input and output conditions. Additionally, the design can incorporate feedback mechanisms to adjust the duty cycle of the MOSFET, ensuring that the output current remains constant despite fluctuations in the supply voltage or load conditions.

The efficiency of buck converters is primarily influenced by several factors, including the on-resistance of the MOSFET, the forward voltage drop of the diode, and the quality of the inductor. Selecting components with low losses and optimizing the layout to minimize parasitic inductances and capacitances can significantly enhance overall efficiency. In high-brightness LED applications, where thermal management is also a concern, maintaining high efficiency is crucial to prevent overheating and ensure reliable operation.

In summary, the buck converter is a versatile and efficient solution for driving LEDs, particularly in applications requiring a stable output current with minimal power loss. Its simplicity, coupled with the ability to achieve high efficiency, makes it a preferred choice among engineers designing LED driver circuits.The first switching LED driver that we will study is the buck converter. The buck converter is the simplest of the switching drivers, and is a step-down converter for applications where the load voltage is never more than about 85% of the supply voltage. The limit of about 85% is due to switching delays in the control system. In a buck converter c ircuit, a power MOSFET is usually used to switch the supply voltage across an inductor and LED load connected in series. The inductor is used to store energy when the MOSFET is turned on; this energy is then used to provide current for the LED when the MOSFET is turned off.

A diode across the LED and inductor circuit provides a return path for the current during the MOSFET off time. A simple schematic is shown in Figure 5. 1. Buck converters are an attractive choice for LED drivers in offline and in low voltage applications as they can produce a constant LED current at very high efficiencies.

A peak-current-controlled buck converter can give reasonable LED current variation over a wide range of input and LED voltages and needs no design effort in feedback control design. Coupled with the fact that these converters can be designed to operate at above 90% efficiencies, the buck-based driver becomes an attractive solution to drive high brightness LEDs.

🔗 External reference