Changes inductive boost LED Driver

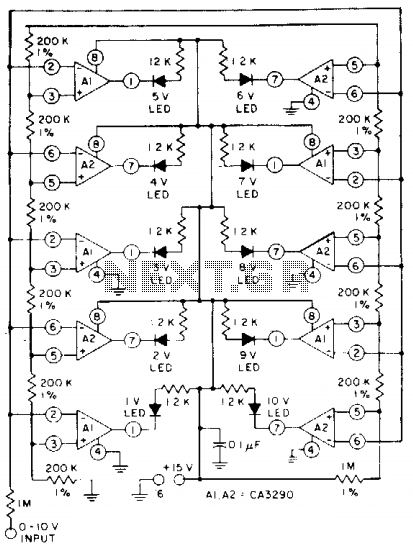

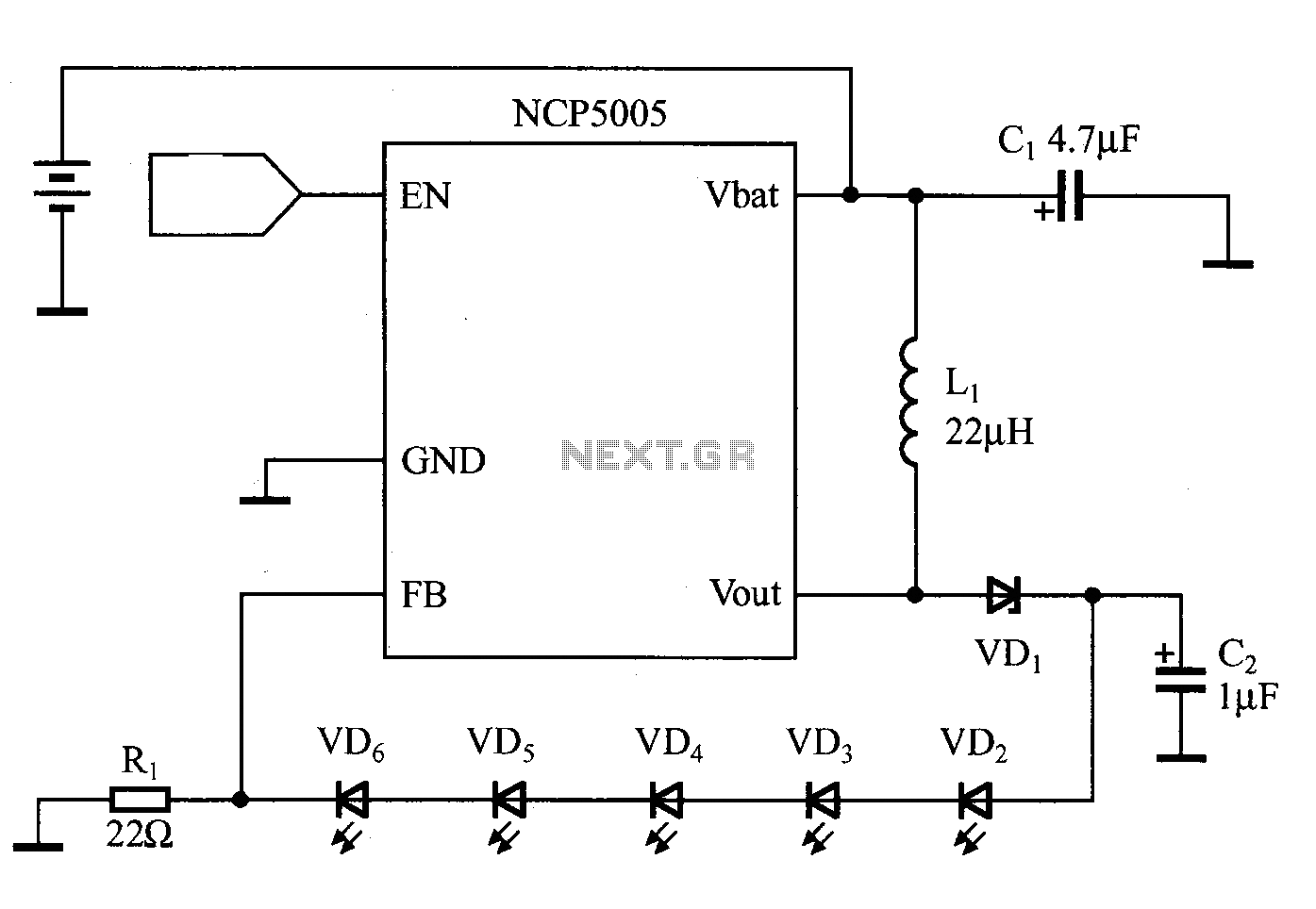

White LEDs can be connected in series or parallel, each method having its own advantages and disadvantages. A key disadvantage of the parallel connection is that the current and brightness of the LEDs do not automatically match. In contrast, series connections maintain inherent characteristics, but they require a higher supply voltage. The typical forward voltage drop of white LEDs is between 3 to 4V. In both configurations, the battery voltage in most portable electronic devices is often insufficient to drive the LEDs, necessitating a separate power supply. In a series setup, the number of LEDs that can be driven is limited by the maximum voltage. For instance, with a maximum voltage of 40V, up to 13 white LEDs can be driven in series, with a drive current ranging from 10 to 350mA in a continuous state. The advantage of this configuration is that a single-wire current can be used for the series of white LEDs; however, a disadvantage arises in situations where PCB space is limited, particularly for high-power applications, as the current density on the copper traces can become an issue. Additionally, if one white LED fails in a series configuration, all LEDs will turn off. From a design perspective, if only white LEDs are used, the battery voltage must be increased to meet the necessary forward voltage, which requires a step-up converter. An inductive element can be employed to accurately monitor the current slope, limiting uncontrolled instantaneous current and EMI. A typical boost topology is illustrated in the accompanying figure.

In electronic circuit design, the choice between series and parallel configurations for white LEDs is critical, as it influences not only the electrical characteristics but also the overall efficiency and reliability of the system. The series connection is often preferred when uniform brightness is essential, as it ensures that the same current flows through each LED, thus maintaining consistent performance. However, the requirement for a higher supply voltage can complicate designs, especially in battery-operated devices where space and weight are at a premium.

The use of a boost converter in the circuit design is a common solution to overcome the voltage limitations posed by battery supplies. This converter steps up the input voltage to a level sufficient to drive the desired number of LEDs in series. The design of the boost converter typically involves an inductor, a diode, a switch (often a transistor), and a capacitor. The inductor stores energy when the switch is closed and releases it to the output when the switch is opened, allowing for a higher voltage to be delivered to the LEDs.

Furthermore, careful consideration must be given to the thermal management of the LEDs and the boost converter, as excessive heat can lead to reduced efficiency and potential failure of components. Heat sinks or thermal pads may be necessary to dissipate heat effectively, ensuring the longevity of the LEDs and maintaining performance.

In summary, the design of LED circuits, whether in series or parallel, requires a thorough understanding of electrical characteristics, power supply limitations, and thermal management to create efficient and reliable lighting solutions.White LED can be used in series or parallel connection, both solutions have advantages and disadvantages. The disadvantage is that parallel the LED current and brightness do not automatically match. Series to maintain the inherent characteristics of the match, but requires a higher supply voltage. Because the white LED forward voltage drop of 3 ~ 4V (typ), either in parallel or in series, the battery voltage is most portable electronic devices are insufficient to drive the LED, so the need for a separate power supply. In a series configuration, the number of LED's that drive the highest voltage limit. If the maximum voltage of 40V, in a series configuration according to the white LED forward voltage, the maximum voltage that can drive up to 13 white LED, the drive current in the range of 10 ~ 350mA continuous state.

Advantage of this configuration is a series of white LED can be used single-wire current; the disadvantage is that when the PCB space is limited (especially when high power), the current density on the copper wire is a problem, but if one in-line mode white LED fails, all white LED will be turned off. However, from a design point of view, if there is a knife only white LED, the battery voltage is necessary to enhance the n Vp, it must step-up structure.

You can use inductance element accurately monitor current slope, limiting the EMI uncontrolled instantaneous current. A typical boost topology shown in Fig.

In electronic circuit design, the choice between series and parallel configurations for white LEDs is critical, as it influences not only the electrical characteristics but also the overall efficiency and reliability of the system. The series connection is often preferred when uniform brightness is essential, as it ensures that the same current flows through each LED, thus maintaining consistent performance. However, the requirement for a higher supply voltage can complicate designs, especially in battery-operated devices where space and weight are at a premium.

The use of a boost converter in the circuit design is a common solution to overcome the voltage limitations posed by battery supplies. This converter steps up the input voltage to a level sufficient to drive the desired number of LEDs in series. The design of the boost converter typically involves an inductor, a diode, a switch (often a transistor), and a capacitor. The inductor stores energy when the switch is closed and releases it to the output when the switch is opened, allowing for a higher voltage to be delivered to the LEDs.

Furthermore, careful consideration must be given to the thermal management of the LEDs and the boost converter, as excessive heat can lead to reduced efficiency and potential failure of components. Heat sinks or thermal pads may be necessary to dissipate heat effectively, ensuring the longevity of the LEDs and maintaining performance.

In summary, the design of LED circuits, whether in series or parallel, requires a thorough understanding of electrical characteristics, power supply limitations, and thermal management to create efficient and reliable lighting solutions.White LED can be used in series or parallel connection, both solutions have advantages and disadvantages. The disadvantage is that parallel the LED current and brightness do not automatically match. Series to maintain the inherent characteristics of the match, but requires a higher supply voltage. Because the white LED forward voltage drop of 3 ~ 4V (typ), either in parallel or in series, the battery voltage is most portable electronic devices are insufficient to drive the LED, so the need for a separate power supply. In a series configuration, the number of LED's that drive the highest voltage limit. If the maximum voltage of 40V, in a series configuration according to the white LED forward voltage, the maximum voltage that can drive up to 13 white LED, the drive current in the range of 10 ~ 350mA continuous state.

Advantage of this configuration is a series of white LED can be used single-wire current; the disadvantage is that when the PCB space is limited (especially when high power), the current density on the copper wire is a problem, but if one in-line mode white LED fails, all white LED will be turned off. However, from a design point of view, if there is a knife only white LED, the battery voltage is necessary to enhance the n Vp, it must step-up structure.

You can use inductance element accurately monitor current slope, limiting the EMI uncontrolled instantaneous current. A typical boost topology shown in Fig.