Controlling the Air Muscle actuators

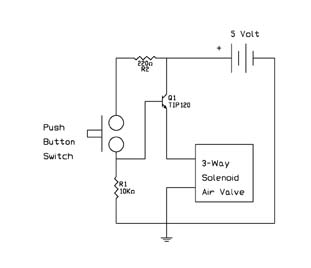

To activate the air muscle, the valve labeled #2 is opened, causing the air muscle to contract. Once activated, the #2 valve can be closed without affecting the state of the air muscle, which remains in a contracted state. To relax the air muscle, air pressure must be vented by opening the valve labeled #1. A three-way stopcock air valve may be purchased, as shown in figure 14. This stopcock air valve allows for manual control of the air muscle. A three-way valve can also be simulated or constructed using two one-way air valves. Small plastic aquarium valves, available at local pet shops, have proven effective; however, they are not rated for operation at 50 psi, necessitating the use of eye protection in case of failure due to air pressure. While manual valves are suitable for testing air muscles, an electronic control mechanism is required for building a robot or industrial device. Fortunately, this is straightforward, as several solenoid air valves are available. The Isonic valves from Mead Fluid Dynamics are preferred; these are 3-way air valves activated by 5 volts, as illustrated in figure 14. The 3-way Isonic valves automatically vent the air muscle through the back when deactivated. In the Isonic valve, valve #1 is normally open, serving as the vent, while valve #2 is normally closed, labeled "In" in figure 14. The air stream directed to the air muscle is labeled "Out" in the same figure. When the electronic valve is activated, valve #2 opens, allowing air pressure to reach the air muscle, while valve #1 closes. Upon deactivation, each valve reverses its state: valve #1 opens to vent the air pressure from the air muscle, and valve #2 closes, isolating the air supply from the air muscle. The front of the Isonic air valve features two quick connects for air tubing. This specific air valve accommodates semi-rigid 4mm tubing, which is an appropriate size for delivering air to the air muscle. To utilize the quick connect, insert the air tubing into the hole until it locks in place. To disconnect, hold the valve flange against the valve body and pull the tubing out.

The air muscle activation system described incorporates a two-valve configuration for effective control of air pressure, enabling both contraction and relaxation of the air muscle. The use of a three-way stopcock air valve allows for manual intervention, which is beneficial during testing and setup phases. However, for automated systems, the integration of solenoid-operated valves like the Isonic valves provides a reliable electronic control mechanism.

The Isonic valve's design features a normally open vent and a normally closed air supply, which simplifies the control logic required for operating the air muscle. By utilizing a 5-volt signal, the electronic control can easily interface with microcontrollers or other logic devices, allowing for precise timing and control of the muscle's operation. The quick connect feature of the Isonic valve enhances the ease of assembly and maintenance, enabling rapid changes or repairs to the system without the need for specialized tools.

For applications requiring robust performance, it is essential to consider the pressure rating of all components used in the system. While plastic aquarium valves are suitable for low-pressure applications, they should be replaced with higher-rated components when operating near the maximum pressure of 50 psi to ensure safety and reliability. The choice of semi-rigid 4mm tubing is also critical, as it must withstand the operational pressures while maintaining flexibility for installation in various configurations.

Overall, the air muscle control system is versatile and can be adapted for various robotic and industrial applications, where precise control of pneumatic actuation is required.To activate the air muscle, valve labeled #2 is opened. This causes the air muscle to contract. Once activated the #2 valve may be closed without impacting on the state of the air muscle. The air muscle stays in a contracted state. To relax the air muscle, the air pressure must be vented by opening valve labeled #1. A three-way stopcock air valve may be purchased, see figure 14. The stopcock air valve allows you to control the air muscle manually. A three-way valve may be simulated or constructed using two one-way air valves. Small plastic aquarium valves purchased at a local pet shop have work quite well. However they are not rated for work at 50 psi and that`s a good reason to wear eye protection, just in case they pop apart from the air pressure. Using manual valves are fine for testing air muscles, to build a robot or industrial device we must provide a way for electronic control.

Fortunately this is not difficult. There are a number of solenoid air valves available. I prefer the Isonic valves from Mead Fluid Dynamics. These are 3-way air valves that are activated using 5 Volts see Figure 14. The 3-way Isonic values automatically vent the air muscle (through the back) when it is deactivated. To see how this particular valve works look back to figure 13, in the Isonic valve, the valve labeled #1 is normally open, this is the vent, through the back of the valve. The valve #2 is normally closed, this is labeled "In" on figure 14. The air stream to the air muscle is labeled "Out" in figure 14. When the electronic valve is activated valve # 2 opens allowing air pressure to the air muscle and valve #1 closes.

When deactivated each valve changes state; valve #1 opens, venting the air muscles air pressure and valve #2 closes separating the air supply from the air muscle. The front of the Isonic air valve has two quick connects-disconnects for air tubing. This particular air valve connects handles semi-ridge 4mm tubing, which is a good size for running air to the air muscle.

To use the quick connect simply push the air tubing into the hole, it will lock in. To disconnect, hold the valve flange to the valve body with your fingers and pull the tubing out. 🔗 External reference

The air muscle activation system described incorporates a two-valve configuration for effective control of air pressure, enabling both contraction and relaxation of the air muscle. The use of a three-way stopcock air valve allows for manual intervention, which is beneficial during testing and setup phases. However, for automated systems, the integration of solenoid-operated valves like the Isonic valves provides a reliable electronic control mechanism.

The Isonic valve's design features a normally open vent and a normally closed air supply, which simplifies the control logic required for operating the air muscle. By utilizing a 5-volt signal, the electronic control can easily interface with microcontrollers or other logic devices, allowing for precise timing and control of the muscle's operation. The quick connect feature of the Isonic valve enhances the ease of assembly and maintenance, enabling rapid changes or repairs to the system without the need for specialized tools.

For applications requiring robust performance, it is essential to consider the pressure rating of all components used in the system. While plastic aquarium valves are suitable for low-pressure applications, they should be replaced with higher-rated components when operating near the maximum pressure of 50 psi to ensure safety and reliability. The choice of semi-rigid 4mm tubing is also critical, as it must withstand the operational pressures while maintaining flexibility for installation in various configurations.

Overall, the air muscle control system is versatile and can be adapted for various robotic and industrial applications, where precise control of pneumatic actuation is required.To activate the air muscle, valve labeled #2 is opened. This causes the air muscle to contract. Once activated the #2 valve may be closed without impacting on the state of the air muscle. The air muscle stays in a contracted state. To relax the air muscle, the air pressure must be vented by opening valve labeled #1. A three-way stopcock air valve may be purchased, see figure 14. The stopcock air valve allows you to control the air muscle manually. A three-way valve may be simulated or constructed using two one-way air valves. Small plastic aquarium valves purchased at a local pet shop have work quite well. However they are not rated for work at 50 psi and that`s a good reason to wear eye protection, just in case they pop apart from the air pressure. Using manual valves are fine for testing air muscles, to build a robot or industrial device we must provide a way for electronic control.

Fortunately this is not difficult. There are a number of solenoid air valves available. I prefer the Isonic valves from Mead Fluid Dynamics. These are 3-way air valves that are activated using 5 Volts see Figure 14. The 3-way Isonic values automatically vent the air muscle (through the back) when it is deactivated. To see how this particular valve works look back to figure 13, in the Isonic valve, the valve labeled #1 is normally open, this is the vent, through the back of the valve. The valve #2 is normally closed, this is labeled "In" on figure 14. The air stream to the air muscle is labeled "Out" in figure 14. When the electronic valve is activated valve # 2 opens allowing air pressure to the air muscle and valve #1 closes.

When deactivated each valve changes state; valve #1 opens, venting the air muscles air pressure and valve #2 closes separating the air supply from the air muscle. The front of the Isonic air valve has two quick connects-disconnects for air tubing. This particular air valve connects handles semi-ridge 4mm tubing, which is a good size for running air to the air muscle.

To use the quick connect simply push the air tubing into the hole, it will lock in. To disconnect, hold the valve flange to the valve body with your fingers and pull the tubing out. 🔗 External reference