DC Motor Tutorial

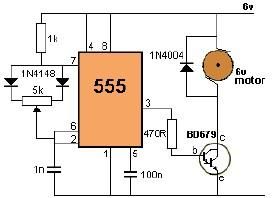

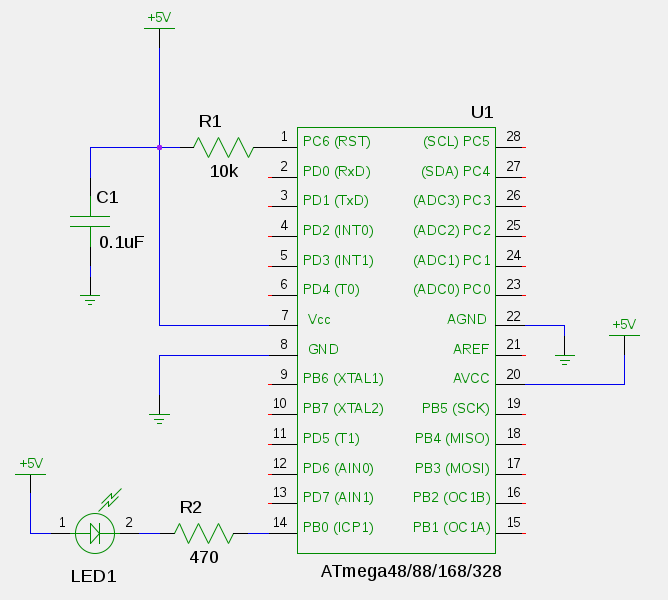

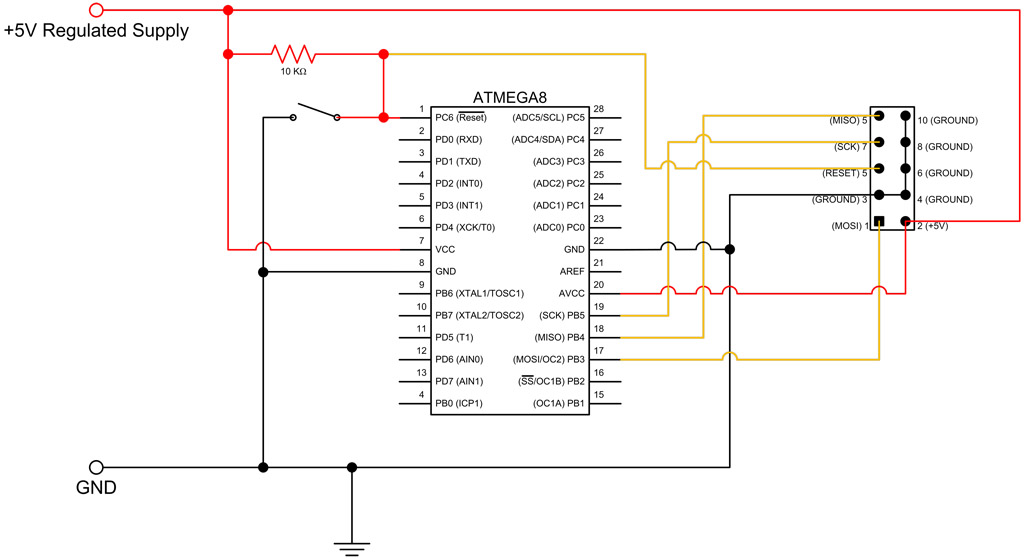

A DC motor operates by converting electrical power into mechanical work. This process involves passing current through a coil, which generates a magnetic field that causes the motor to spin. One method to adjust the speed of a DC motor is by changing the voltage applied to the coil. To achieve this using a microcontroller, Pulse Width Modulation (PWM) output must be employed, allowing the duty cycle to be modified, which in turn alters the average voltage output and consequently changes the motor's speed. To control a DC motor with a microcontroller, it is necessary to use a buffer or an H-bridge driver, as the current requirements exceed what the microcontroller can provide directly. An example schematic illustrates how to connect the motor for bidirectional operation (forward and reverse) using an L298 driver connected to a microcontroller with PWM for speed control.

A DC motor is an electromechanical device that converts electrical energy into mechanical energy through the interaction of magnetic fields. The fundamental operation involves a rotating coil situated within a magnetic field, where the application of electric current induces movement. The speed of a DC motor can be effectively controlled by varying the voltage supplied to the coil, which can be accomplished using PWM techniques.

PWM involves switching the power supplied to the motor on and off at a high frequency, effectively controlling the average voltage and current reaching the motor. By adjusting the duty cycle of the PWM signal, the average voltage can be increased or decreased, thus providing a means to fine-tune the motor's speed.

In practical applications, a microcontroller typically generates the PWM signal. However, due to the limited current output capabilities of microcontrollers, an intermediary component such as a buffer or an H-bridge driver is necessary to handle the higher current requirements of the motor. The H-bridge configuration allows for the reversal of motor direction, providing flexibility in motor control.

The L298 driver is a common choice for driving DC motors as it can control two motors independently and can handle the necessary current and voltage levels. In a typical setup, the microcontroller outputs PWM signals to the L298 driver, which in turn regulates the power supplied to the motor. The schematic for this configuration would include connections from the microcontroller to the input pins of the L298, as well as connections to the motor terminals, ensuring that the system can operate in both forward and reverse directions while maintaining precise speed control.

This approach not only enhances the control of the motor but also protects the microcontroller from potential damage due to excessive current draw. Properly designed, this system can achieve efficient and reliable performance in various applications requiring precise motor control.A DC motor worksby converting electricpower into mechanical work. This is accomplished by forcing current through a coil and producing a magnetic field that spins the motor. One technique to vary the speed of a DC motor is by varying the voltage on the coil. To do this with a microcontroller, PWM output must be used so that the Duty cycle can be c hanged and automatically the average voltage output will be changed too. Consequently the speed ofthe motorwill be changed. This can be seen in the figure below: To drivea dc motor from amicro-controller, there must be a buffer or an H-bridgedriverso thatthe motorwill not be driven directly by the micro because the current needed is not sufficient. The schematic below shows an example how to connectthe motorto be driven in both direction (foward and reverse) with an L298driverand connected to a microcontroler (using PWM to control the speed control).

🔗 External reference

A DC motor is an electromechanical device that converts electrical energy into mechanical energy through the interaction of magnetic fields. The fundamental operation involves a rotating coil situated within a magnetic field, where the application of electric current induces movement. The speed of a DC motor can be effectively controlled by varying the voltage supplied to the coil, which can be accomplished using PWM techniques.

PWM involves switching the power supplied to the motor on and off at a high frequency, effectively controlling the average voltage and current reaching the motor. By adjusting the duty cycle of the PWM signal, the average voltage can be increased or decreased, thus providing a means to fine-tune the motor's speed.

In practical applications, a microcontroller typically generates the PWM signal. However, due to the limited current output capabilities of microcontrollers, an intermediary component such as a buffer or an H-bridge driver is necessary to handle the higher current requirements of the motor. The H-bridge configuration allows for the reversal of motor direction, providing flexibility in motor control.

The L298 driver is a common choice for driving DC motors as it can control two motors independently and can handle the necessary current and voltage levels. In a typical setup, the microcontroller outputs PWM signals to the L298 driver, which in turn regulates the power supplied to the motor. The schematic for this configuration would include connections from the microcontroller to the input pins of the L298, as well as connections to the motor terminals, ensuring that the system can operate in both forward and reverse directions while maintaining precise speed control.

This approach not only enhances the control of the motor but also protects the microcontroller from potential damage due to excessive current draw. Properly designed, this system can achieve efficient and reliable performance in various applications requiring precise motor control.A DC motor worksby converting electricpower into mechanical work. This is accomplished by forcing current through a coil and producing a magnetic field that spins the motor. One technique to vary the speed of a DC motor is by varying the voltage on the coil. To do this with a microcontroller, PWM output must be used so that the Duty cycle can be c hanged and automatically the average voltage output will be changed too. Consequently the speed ofthe motorwill be changed. This can be seen in the figure below: To drivea dc motor from amicro-controller, there must be a buffer or an H-bridgedriverso thatthe motorwill not be driven directly by the micro because the current needed is not sufficient. The schematic below shows an example how to connectthe motorto be driven in both direction (foward and reverse) with an L298driverand connected to a microcontroler (using PWM to control the speed control).

🔗 External reference