DCC Detectors Construction For Model Railroad Signals

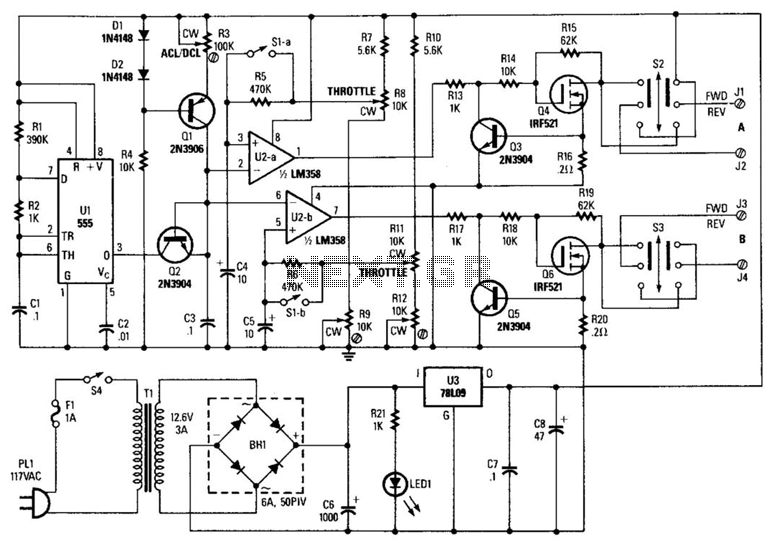

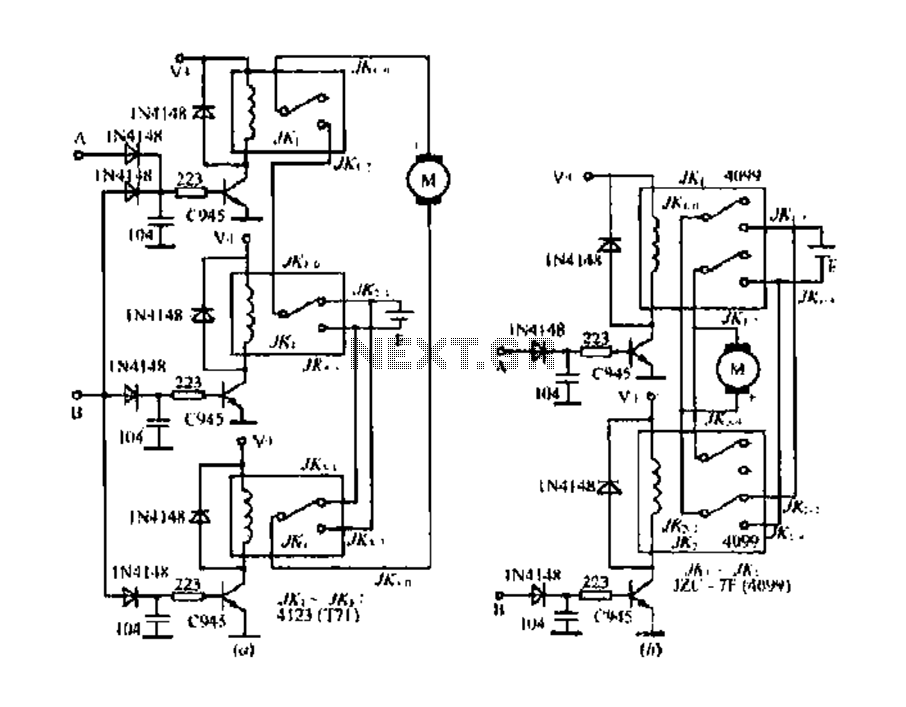

This article falls under the "you can do it too" category. It is not as difficult as one might imagine for the average model railroader, especially with the information available online and articles like this to guide the process. There has been a search for methods to construct personal detectors and signal circuits to reduce costs. Additionally, there is considerable satisfaction derived from proving personal capabilities. A basic understanding of electronics is sufficient, including the ability to follow a schematic, read a meter, and solder. The remainder involves a methodical approach and careful verification of work, often referred to as a "smoke test," as there is a desire to avoid any smoke. Bill Payne, a fellow member of the Nottawasaga Model Railroad Club (NMRC), possesses a greater knowledge of electronics and is leading this project. The NMRC layout has recently been upgraded to Digital Command Control (DCC), and there is an intention to install signals on the layout. Changing signals captivates audiences at train shows, even if the signal indications are not entirely accurate. Prior to Christmas 2009, Bill and another member had constructed and tested some signal circuits sourced from the Internet. The next phase involved developing detector circuits compatible with DCC, specifically designed by R. Paisley. One block occupancy detector utilizes a 555 timer, while another is based on a 339 comparator. Both detectors draw power directly from one rail, with the power wire passing through a small transformer. This transformer detects voltage changes when a train occupies a block and relays this information to the signal controllers. This description simplifies the electronic function. The circuits designed by R. Paisley are reported to perform similarly. Bill is also investigating whether they can be adapted for Direct Current (DC) on his non-DCC home layout. The sensitivity of the transformers for detecting current changes can be adjusted by altering the number of loops of wire passing through the center of the transformer. The second schematic for DCC detectors is based on a 339 comparator, which can be obtained as a single chip, such as the 393. The dual nature of the 339 allows for more circuits to be integrated onto a single board. Bill arranged four DCC detectors on one stripboard. This process requires meticulous attention to detail. He began by sketching the circuit layout on a Stripboard Planning Sheet, indicating component placement for the DCC detectors. Red dots on the plan signify where to cut traces on the copper side of the board. The top line on one side of the board is designated for 12+ volts, while the first line on the opposite side is for 12- volts. Once the paper plan was verified against the schematic, Bill carefully cut the traces using a drill bit in a Dremel tool, although an X-Acto blade can also be used; the drill bit is preferred for ensuring complete trace cuts. In case of mistakes, jumper wires can be added. Bill configured four blocks on a single piece of stripboard, which served as the final "beta-test" board to drive the signal logic. Alligator clips were used to connect to the live rails on the main layout, specifically at Utopia East near the workbench. A simple DC power pack, originally from a President's Choice train set, supplied the 12-volt power for the circuits, with a meter used to adjust the voltage to approximately 12 volts. On January 27, 2010, while other operators engaged with the trains on the Utopia Northern layout, Bill and another individual activated the circuit. There was no smoke, indicating successful operation, although one block malfunctioned due to two pads for the chip that had not been soldered. For this setup, an old 3-foot section of HO track was utilized, featuring fiber ties and brass rails attached to the fiber ties.

The circuit design for the DCC detector involves two primary components: a transformer for detecting occupancy and a comparator for processing the signal. The transformer is placed in series with the track, allowing it to sense the current change caused by a train passing over. The 555 timer circuit can be used for simple timing functions, while the 339 comparator circuit is more complex and allows for dual-channel detection. The output from the comparator can be connected to signal controllers, which will then manage the visual signals displayed on the layout.

The stripboard layout requires careful planning to ensure that the components are correctly placed and that the traces are cut accurately. The design should also consider power distribution and signal integrity, ensuring that the detectors operate reliably under varying load conditions. Proper soldering techniques are crucial to ensure good electrical connections and to prevent issues such as cold solder joints, which can lead to intermittent failures.

In summary, the project encompasses the design and construction of DCC-compatible block occupancy detectors, emphasizing the importance of methodical planning, component selection, and circuit layout for successful implementation in model railroad applications.This article is in the "you can do it too" category. It`s not as difficult as you can imagine for the average model railroader, especially with the information available on the Internet and with articles like this to guide you. I have been looking for a way to construct my own detectors and signal circuits to keep the cost down.

Also, there`s a lo t of satisfaction that comes from proving to yourself that you can do it. I don`t know a lot about electronics, but I can follow a schematic, I can read a meter, and I know how to solder. The rest falls into the category of "take it one step at a time and doublecheck what you`re doing". Sometimes this is referred to as a "smoke test". You don`t want to see smoke! Bill Payne, fellow member at our Nottawasaga Model Railroad Club (NMRC) knows more about electronics than I do so he is taking the lead on this project.

The NMRC layout has just been upgraded to DCC and we would also like to install signals on the layout. There`s nothing like changing signals to keep people fascinated at train shows, even if the indications of the signals aren`t quite right!

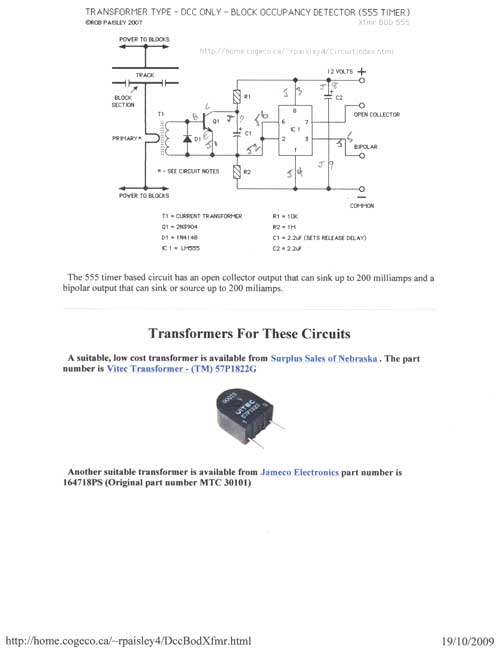

Before Christmas, 2009, Bill and I had already built and tested some signal circuits we had found on the Internet. The next step was to build some detector circuits that would work for DCC. The ones we are working with were designed by R. Paisley. One of the block occupancy detectors is designed around a 555 timer and the other is based on a 339 comparator.

Both take power directly from one rail. The wire with the power passes through the hole in a small transformer. The transformer detects a change in voltage when a train occupies a block and passes this information to the signal controllers. That`s sort of a non-electronic way of describing what`s going on. Here are the circuits by R. Paisley. We found that both work about the same. Bill is trying to see if they will also work for DC on his home layout that is not DCC. The sensitivity of the transformers for detecting the current change can be changed by the number of loops in the wire through the center hole.

The second schematic for DCC detectors shown above is based around a 339 comparator. You can buy a single comparator chip, I beileve it`s the 393. The 339, being a dual, allows more circuits to be built on one board. Bill laid out four DCC detectors on one piece of stripboard. This is where you really have to take your time. He started by laying out the circuit on paper using a Stripboard Planning Sheet. This paper layout shows where to insert components for the DCC detectors. The red dots on the plan indicate where to cut the traces on the copper side of the board. Bill kept the top line on one side of the board for 12+ volts and the first line on the opposite side is 12- volts. Once he was satisfied that the paper plan matched the schematic he turned the board over and carefully cut the traces by using a drill bit in a Dremel.

You can also use an X-Acto blade, but Bill feels the drill bit is a better guarantee that the trace is cut all the way through. If you mess up, you can always add a jumper wire. Bill laid out 4 blocks on one piece of stripboard. This is the final "beta-test" board we used to drive the signal logic. We used a couple of alligator clips to live rails on the main layout (actually at Utopia East which is near the workbench).

The 12 volt power for the circuits is supplied by a simple DC power pack that came with a President`s Choice train set. We used a meter to adjust the voltage to close to 12 volts. Last night (January 27, 2010), while my other operators played with the trains on my Utopia Northern layout, Bill and I fired up the circuit.

Well, not really "fired up". No smoke! One block wasn`t working properly. We traced it to two pads for the chip that hadn`t been soldered. For our setup I used an old 3-foot piece of HO track. How old You guess. Fiber ties, brass rails stapled to the fiber ties. 🔗 External reference

The circuit design for the DCC detector involves two primary components: a transformer for detecting occupancy and a comparator for processing the signal. The transformer is placed in series with the track, allowing it to sense the current change caused by a train passing over. The 555 timer circuit can be used for simple timing functions, while the 339 comparator circuit is more complex and allows for dual-channel detection. The output from the comparator can be connected to signal controllers, which will then manage the visual signals displayed on the layout.

The stripboard layout requires careful planning to ensure that the components are correctly placed and that the traces are cut accurately. The design should also consider power distribution and signal integrity, ensuring that the detectors operate reliably under varying load conditions. Proper soldering techniques are crucial to ensure good electrical connections and to prevent issues such as cold solder joints, which can lead to intermittent failures.

In summary, the project encompasses the design and construction of DCC-compatible block occupancy detectors, emphasizing the importance of methodical planning, component selection, and circuit layout for successful implementation in model railroad applications.This article is in the "you can do it too" category. It`s not as difficult as you can imagine for the average model railroader, especially with the information available on the Internet and with articles like this to guide you. I have been looking for a way to construct my own detectors and signal circuits to keep the cost down.

Also, there`s a lo t of satisfaction that comes from proving to yourself that you can do it. I don`t know a lot about electronics, but I can follow a schematic, I can read a meter, and I know how to solder. The rest falls into the category of "take it one step at a time and doublecheck what you`re doing". Sometimes this is referred to as a "smoke test". You don`t want to see smoke! Bill Payne, fellow member at our Nottawasaga Model Railroad Club (NMRC) knows more about electronics than I do so he is taking the lead on this project.

The NMRC layout has just been upgraded to DCC and we would also like to install signals on the layout. There`s nothing like changing signals to keep people fascinated at train shows, even if the indications of the signals aren`t quite right!

Before Christmas, 2009, Bill and I had already built and tested some signal circuits we had found on the Internet. The next step was to build some detector circuits that would work for DCC. The ones we are working with were designed by R. Paisley. One of the block occupancy detectors is designed around a 555 timer and the other is based on a 339 comparator.

Both take power directly from one rail. The wire with the power passes through the hole in a small transformer. The transformer detects a change in voltage when a train occupies a block and passes this information to the signal controllers. That`s sort of a non-electronic way of describing what`s going on. Here are the circuits by R. Paisley. We found that both work about the same. Bill is trying to see if they will also work for DC on his home layout that is not DCC. The sensitivity of the transformers for detecting the current change can be changed by the number of loops in the wire through the center hole.

The second schematic for DCC detectors shown above is based around a 339 comparator. You can buy a single comparator chip, I beileve it`s the 393. The 339, being a dual, allows more circuits to be built on one board. Bill laid out four DCC detectors on one piece of stripboard. This is where you really have to take your time. He started by laying out the circuit on paper using a Stripboard Planning Sheet. This paper layout shows where to insert components for the DCC detectors. The red dots on the plan indicate where to cut the traces on the copper side of the board. Bill kept the top line on one side of the board for 12+ volts and the first line on the opposite side is 12- volts. Once he was satisfied that the paper plan matched the schematic he turned the board over and carefully cut the traces by using a drill bit in a Dremel.

You can also use an X-Acto blade, but Bill feels the drill bit is a better guarantee that the trace is cut all the way through. If you mess up, you can always add a jumper wire. Bill laid out 4 blocks on one piece of stripboard. This is the final "beta-test" board we used to drive the signal logic. We used a couple of alligator clips to live rails on the main layout (actually at Utopia East which is near the workbench).

The 12 volt power for the circuits is supplied by a simple DC power pack that came with a President`s Choice train set. We used a meter to adjust the voltage to close to 12 volts. Last night (January 27, 2010), while my other operators played with the trains on my Utopia Northern layout, Bill and I fired up the circuit.

Well, not really "fired up". No smoke! One block wasn`t working properly. We traced it to two pads for the chip that hadn`t been soldered. For our setup I used an old 3-foot piece of HO track. How old You guess. Fiber ties, brass rails stapled to the fiber ties. 🔗 External reference