Delay Switch

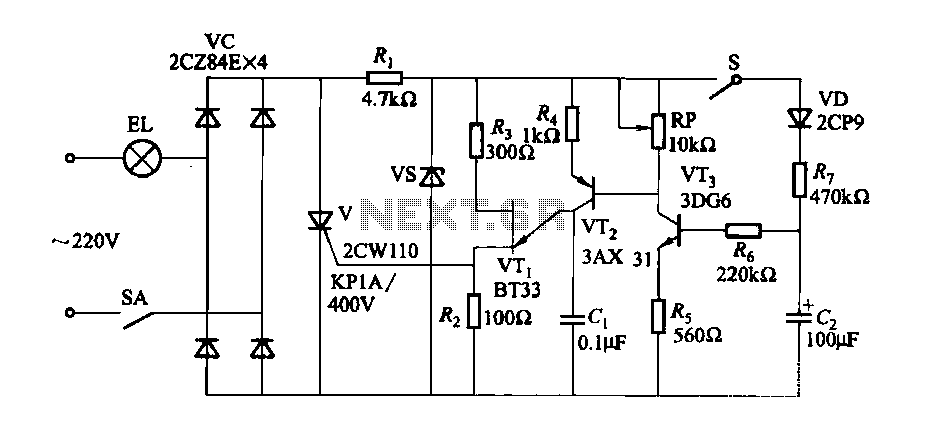

This switch allows the model train at such a station to automatically slow down. The train stands for a certain amount of time and then slowly pulls back. You do not need to stop the train. The relatively simple circuit works. P1 potentiometer for setting the waiting time, while turning to A causes a shorter waiting time and turning to B results in a longer waiting period. P2 is to set the brake and acceleration. Here, too, turning to A results in faster acceleration and the train slows.

The connections of the switch are also simple. The indicated connections on the track with the switch connected. In the broken piece of the train, it will slow down and wait. At H0, this piece is about 1 meter, and at 0.5 N m. Of course, this also depends on the length of the train. When the circuit is connected as shown, the train will stop in one direction only. To allow the train to stop in both directions, a bridge rectifier should be mounted between the rail terminals and the circuit with the AC terminals on the rails, plus the 'rails' terminal and ground to the 'output' connection. A switch can also be installed on the two terminals of the switch. When the switch is closed, the train stops and does not just drive by. A final transistor T3 requires a small heat sink to be mounted. The switch can then handle a current of up to 2 A.

R1 = 150 kOhm

R2 = 22 kOhm

R3 = 0.22 Ω / 2 W

R4 = 1 kOhm

P1 = 100 kOhm

P2 = 10 kΩ

C1 = 220 V µF/16

C2, C3 = 47 µF/16 V

T1, D2 = 1N4002

T1, T4 = 547 BC

T2 = 517 BC

T3 = BD 433

The described circuit functions as a control mechanism for model trains, particularly at stations where a stop-and-go operation is desired. The use of two potentiometers (P1 and P2) allows for user-defined adjustments of waiting time and acceleration rates, enhancing the flexibility of the system. P1 adjusts the duration the train remains stationary, with the ability to fine-tune this based on operational requirements. P2 governs the rate of acceleration and deceleration, allowing for a more realistic train operation.

The circuit utilizes a combination of resistors (R1, R2, R3, R4) to set appropriate biasing levels and current limits for the transistors (T1, T2, T3, T4), which act as switches to control the flow of current to the train's motor. The inclusion of capacitors (C1, C2, C3) serves to filter voltage spikes and stabilize the power supply, ensuring smooth operation of the circuit.

In terms of connectivity, the circuit is designed to be straightforward, allowing for easy integration with existing model train setups. The suggestion to use a bridge rectifier for bi-directional operation indicates a level of sophistication in the design, accommodating trains that may need to reverse direction without requiring manual intervention.

The specifications for the components suggest a robust design capable of handling the electrical demands of model train operation, particularly with the transistor T3 rated for a current of up to 2 A, making it suitable for most model train motors. The heat sink requirement for T3 further indicates that the circuit is designed to dissipate heat effectively, ensuring reliability during extended use.

Overall, this circuit provides a practical solution for automating model train operations at stations, enhancing user experience through adjustable parameters and reliable performance.This switch allows the model train at such a station will automatically slow down. The train stands for a certain amount of time and then slowly pulls back. You do not own the train to stop. The relatively simple circuit works. P1 potentiometer for setting the waiting time, while turning to A caused a shorter waiting time and turn to B results in a longer waiting period. P2 is to set the brake and acceleratieweg. Here, too, turn to A results in faster acceleration and the train slows. The connections of the switch are also simple (see picture connections). The indicated connections on track with the switch connected. In the broken piece of the train will slow down and wait. At H0, this piece is about 1 meter to be, and at 0.5 N m. Of course this also depends on the length of the train. When the circuit is connected as shown, the train will stop in one direction only. Want to train in both directions to stop, then mount a bridge rectifier between the rail terminals and the circuit with the AC terminals on the rails, plus the 'rails' terminal and ground to the' uitgang' connection. You can also stop off. Install a switch on the two terminals of the switch. When the switch is closed, the train stops and not just drive by. Final Transistor T3 is a small heat sink to be screwed. The switch can then flow up to 2 A. R1 = 150 kOhm R2 = 22 kOhm R3 = 0.22 ? / 2 W R4 = 1 kOhm P1 = 100 kOhm P2 = 10kW C1 = 220 V ?F/16 C2, C3 = 47 ?F/16 V T1, D2 = 1N4002 T1, T4 = 547 BC T2 = 517 BC T3 = BD 433

🔗 External reference

The connections of the switch are also simple. The indicated connections on the track with the switch connected. In the broken piece of the train, it will slow down and wait. At H0, this piece is about 1 meter, and at 0.5 N m. Of course, this also depends on the length of the train. When the circuit is connected as shown, the train will stop in one direction only. To allow the train to stop in both directions, a bridge rectifier should be mounted between the rail terminals and the circuit with the AC terminals on the rails, plus the 'rails' terminal and ground to the 'output' connection. A switch can also be installed on the two terminals of the switch. When the switch is closed, the train stops and does not just drive by. A final transistor T3 requires a small heat sink to be mounted. The switch can then handle a current of up to 2 A.

R1 = 150 kOhm

R2 = 22 kOhm

R3 = 0.22 Ω / 2 W

R4 = 1 kOhm

P1 = 100 kOhm

P2 = 10 kΩ

C1 = 220 V µF/16

C2, C3 = 47 µF/16 V

T1, D2 = 1N4002

T1, T4 = 547 BC

T2 = 517 BC

T3 = BD 433

The described circuit functions as a control mechanism for model trains, particularly at stations where a stop-and-go operation is desired. The use of two potentiometers (P1 and P2) allows for user-defined adjustments of waiting time and acceleration rates, enhancing the flexibility of the system. P1 adjusts the duration the train remains stationary, with the ability to fine-tune this based on operational requirements. P2 governs the rate of acceleration and deceleration, allowing for a more realistic train operation.

The circuit utilizes a combination of resistors (R1, R2, R3, R4) to set appropriate biasing levels and current limits for the transistors (T1, T2, T3, T4), which act as switches to control the flow of current to the train's motor. The inclusion of capacitors (C1, C2, C3) serves to filter voltage spikes and stabilize the power supply, ensuring smooth operation of the circuit.

In terms of connectivity, the circuit is designed to be straightforward, allowing for easy integration with existing model train setups. The suggestion to use a bridge rectifier for bi-directional operation indicates a level of sophistication in the design, accommodating trains that may need to reverse direction without requiring manual intervention.

The specifications for the components suggest a robust design capable of handling the electrical demands of model train operation, particularly with the transistor T3 rated for a current of up to 2 A, making it suitable for most model train motors. The heat sink requirement for T3 further indicates that the circuit is designed to dissipate heat effectively, ensuring reliability during extended use.

Overall, this circuit provides a practical solution for automating model train operations at stations, enhancing user experience through adjustable parameters and reliable performance.This switch allows the model train at such a station will automatically slow down. The train stands for a certain amount of time and then slowly pulls back. You do not own the train to stop. The relatively simple circuit works. P1 potentiometer for setting the waiting time, while turning to A caused a shorter waiting time and turn to B results in a longer waiting period. P2 is to set the brake and acceleratieweg. Here, too, turn to A results in faster acceleration and the train slows. The connections of the switch are also simple (see picture connections). The indicated connections on track with the switch connected. In the broken piece of the train will slow down and wait. At H0, this piece is about 1 meter to be, and at 0.5 N m. Of course this also depends on the length of the train. When the circuit is connected as shown, the train will stop in one direction only. Want to train in both directions to stop, then mount a bridge rectifier between the rail terminals and the circuit with the AC terminals on the rails, plus the 'rails' terminal and ground to the' uitgang' connection. You can also stop off. Install a switch on the two terminals of the switch. When the switch is closed, the train stops and not just drive by. Final Transistor T3 is a small heat sink to be screwed. The switch can then flow up to 2 A. R1 = 150 kOhm R2 = 22 kOhm R3 = 0.22 ? / 2 W R4 = 1 kOhm P1 = 100 kOhm P2 = 10kW C1 = 220 V ?F/16 C2, C3 = 47 ?F/16 V T1, D2 = 1N4002 T1, T4 = 547 BC T2 = 517 BC T3 = BD 433

🔗 External reference