Switchless NiCd-NiMH Battery Charger

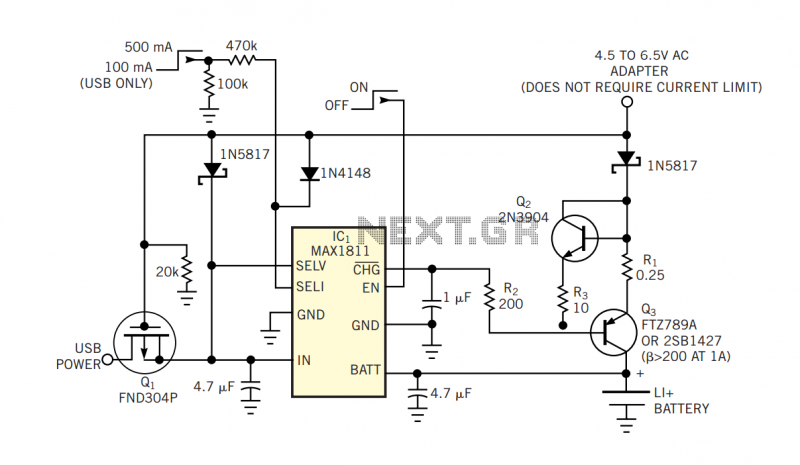

This circuit can be utilized as a replacement for the single current-limiting resistor typically found in low-cost battery chargers. The alternative presented here is advantageous because it prevents the premature failure of nickel-cadmium (NiCd) batteries, which often occur after a few months of improper charging with standard chargers. The circuit diagram features an LM317 configured for constant current operation, but it does not include the usual fixed or variable resistor at the adjustment (ADJ) pin to set the output current. Additionally, there is no switch with multiple resistors to select charging currents for various battery types, such as AAA, AA, and PP3 (6F22). When an empty AAA cell is connected, the voltage across R1 activates transistor T1 via a voltage drop across diode D1, allowing approximately 50 µA to flow from the LM317's ADJ pin into the cell, thus engaging the circuit in constant current mode. Diode D4 is included to prevent the battery from discharging when the charger is turned off or when there is no supply voltage. The charging current (I) is determined by the relationship R(n) = (1.25 + Vsat) / I, where Vsat is 0.1 V. The charging current should ideally be set to one-tenth of the nominal battery capacity; for instance, a charging current of 170 mA is suitable for a 1700 mAh NiCd AA cell. It is important to note that PP3 rechargeable batteries typically consist of seven NiCd cells, resulting in a nominal voltage of 8.4 V, rather than the often assumed 9 V. If higher charging currents are necessary, the power dissipation across resistors R1, R2, and R3 must be considered. As a guideline, the input voltage required for the charger should exceed three times the voltage of the cell or battery pack to accommodate the LM317's dropout voltage and the voltage across R(n). Finally, the LM317 should be equipped with a small heat sink. For safety, it is advisable to use a general-purpose mains adapter with a DC output rather than a dedicated mains transformer/rectifier combination.

This circuit design effectively addresses the limitations of conventional battery chargers by employing the LM317 voltage regulator in a constant current configuration. The circuit's simplicity eliminates the need for variable resistors or complex switching mechanisms, making it a robust solution for charging different battery types.

The LM317 operates by maintaining a constant output current determined by the resistor network formed by R1, R2, and R3. The choice of these resistors directly influences the charging current, ensuring that it remains within safe limits for the specific battery being charged. The inclusion of diodes D1 and D4 enhances the circuit's reliability by providing necessary biasing for the transistor and preventing reverse current flow, respectively.

Thermal management is crucial in this design, particularly when charging larger capacity batteries that may require higher currents. The power dissipation across the resistors and the LM317 must be calculated to prevent overheating, necessitating the use of a heat sink.

The design also emphasizes electrical safety by recommending the use of a mains adapter with a DC output, which provides a safer alternative to traditional transformer-based chargers. This consideration is essential in ensuring user safety and prolonging the lifespan of the charging circuit.

In summary, this circuit offers a practical, efficient, and reliable method for charging NiCd batteries while addressing common issues associated with traditional chargers, including battery life and electrical safety.This circuit may be used to replace the single current limiting resistor often found in dirt cheap battery chargers. The alternative shown here will eventually pay off because you no longer have to throw away your NiCds after three months or so of maltreatment in the original charger.

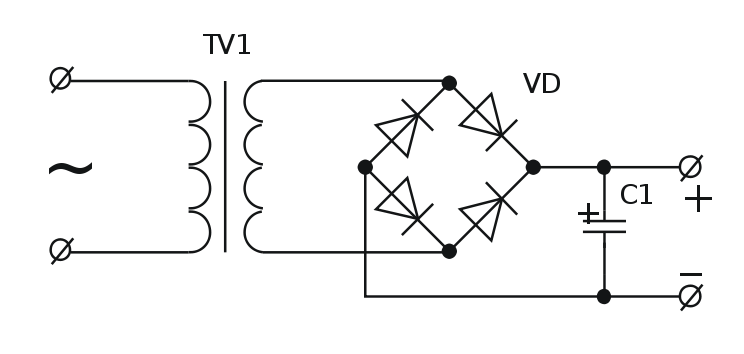

The circuit diagram shows an LM317 in constant-current configur ation but without the usual fixed or variable resistor at the ADJ pin to determine the amount of output current. Also, there is no switch with an array of different resistors to select the charge currents for three cell or battery types we wish to charge: AAA, AA and PP3 (6F22).

When, for example, an empty AAA cell is connected, the voltage developed across R1 causes T1 to be biased via voltage dropper D1. This results in about 50 µA flowing from the LM317`s ADJ pin into the cell, activating the circuit into constant-current mode.

D4 is included to prevent the battery being discharged when the charger is switched off or without a supply voltage. The charging current I is determined by R1/R3/R3 as in R(n) = (1. 25 + Vsat) / I where Vsat is 0. 1 V. The current should be one tenth of the nominal battery capacity ” for example, 170 mA for a 1700-mAh NiCd AA cell.

It should be noted that PP3` rechargeable batteries usually contain seven NiCd cells so their nominal voltage is 8. 4 V and not 9V as is often thought. If relatively high currents are needed, the power dissipation in R1/R2/R3 becomes an issue. As a rule of thumb, the input voltage required by the charger should be greater than three times the cell or battery (pack) voltage.

This is necessary to cover the LM317`s dropout voltage and the voltage across R(n). Two final notes: the LM317 should be fitted with a small heat sink. With electrical safety in mind the use of a general-purpose mains adapter with DC output is preferred over a dedicated mains transformer/rectifier combination. Be the first of your friends to get free diy electronics projects, circuits diagrams, hacks, mods, gadgets & gizmo automatically each time we publish.

Your email address & privacy are safe with us ! 🔗 External reference

This circuit design effectively addresses the limitations of conventional battery chargers by employing the LM317 voltage regulator in a constant current configuration. The circuit's simplicity eliminates the need for variable resistors or complex switching mechanisms, making it a robust solution for charging different battery types.

The LM317 operates by maintaining a constant output current determined by the resistor network formed by R1, R2, and R3. The choice of these resistors directly influences the charging current, ensuring that it remains within safe limits for the specific battery being charged. The inclusion of diodes D1 and D4 enhances the circuit's reliability by providing necessary biasing for the transistor and preventing reverse current flow, respectively.

Thermal management is crucial in this design, particularly when charging larger capacity batteries that may require higher currents. The power dissipation across the resistors and the LM317 must be calculated to prevent overheating, necessitating the use of a heat sink.

The design also emphasizes electrical safety by recommending the use of a mains adapter with a DC output, which provides a safer alternative to traditional transformer-based chargers. This consideration is essential in ensuring user safety and prolonging the lifespan of the charging circuit.

In summary, this circuit offers a practical, efficient, and reliable method for charging NiCd batteries while addressing common issues associated with traditional chargers, including battery life and electrical safety.This circuit may be used to replace the single current limiting resistor often found in dirt cheap battery chargers. The alternative shown here will eventually pay off because you no longer have to throw away your NiCds after three months or so of maltreatment in the original charger.

The circuit diagram shows an LM317 in constant-current configur ation but without the usual fixed or variable resistor at the ADJ pin to determine the amount of output current. Also, there is no switch with an array of different resistors to select the charge currents for three cell or battery types we wish to charge: AAA, AA and PP3 (6F22).

When, for example, an empty AAA cell is connected, the voltage developed across R1 causes T1 to be biased via voltage dropper D1. This results in about 50 µA flowing from the LM317`s ADJ pin into the cell, activating the circuit into constant-current mode.

D4 is included to prevent the battery being discharged when the charger is switched off or without a supply voltage. The charging current I is determined by R1/R3/R3 as in R(n) = (1. 25 + Vsat) / I where Vsat is 0. 1 V. The current should be one tenth of the nominal battery capacity ” for example, 170 mA for a 1700-mAh NiCd AA cell.

It should be noted that PP3` rechargeable batteries usually contain seven NiCd cells so their nominal voltage is 8. 4 V and not 9V as is often thought. If relatively high currents are needed, the power dissipation in R1/R2/R3 becomes an issue. As a rule of thumb, the input voltage required by the charger should be greater than three times the cell or battery (pack) voltage.

This is necessary to cover the LM317`s dropout voltage and the voltage across R(n). Two final notes: the LM317 should be fitted with a small heat sink. With electrical safety in mind the use of a general-purpose mains adapter with DC output is preferred over a dedicated mains transformer/rectifier combination. Be the first of your friends to get free diy electronics projects, circuits diagrams, hacks, mods, gadgets & gizmo automatically each time we publish.

Your email address & privacy are safe with us ! 🔗 External reference