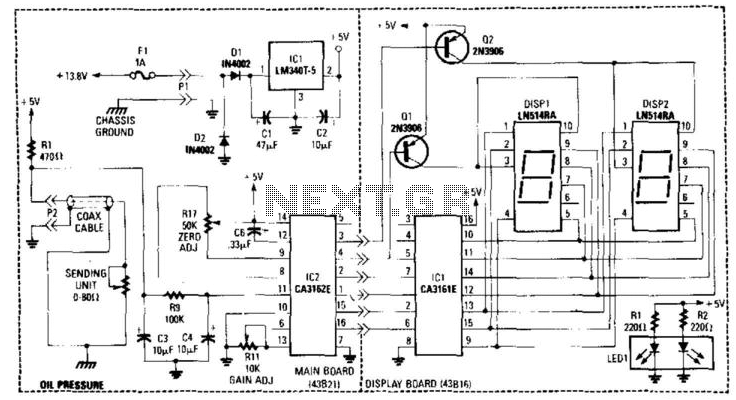

Digital Oil-Pressure Gauge

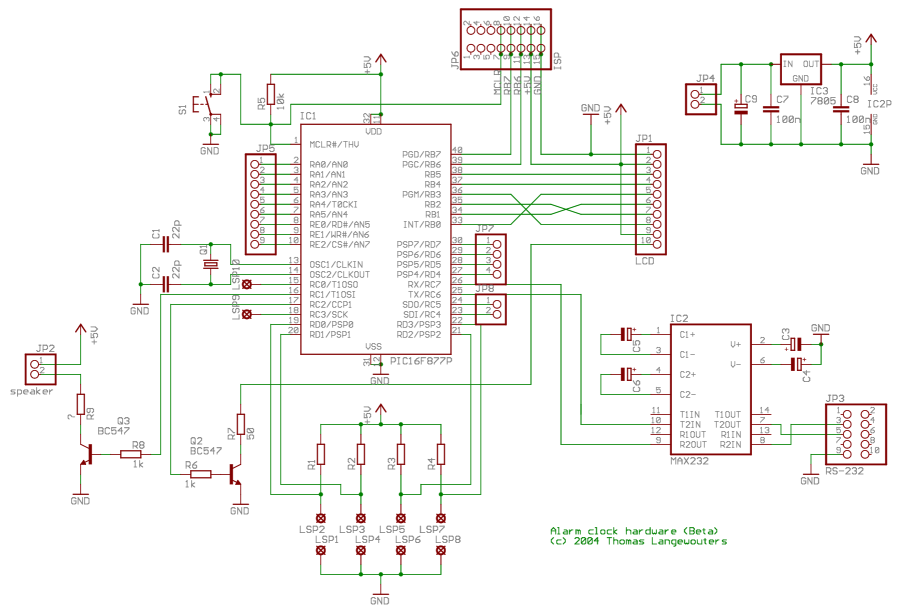

This gauge utilizes a sensor along with resistor R1 to generate a DC voltage that is proportional to oil pressure. Integrated circuits IC1 and IC2 form a two-digit digital voltmeter (DVM). Transistors Q1 and Q2 act as display selectors for the multiplexed display. IC1 supplies the required +5 V to the circuitry. Calibration is achieved through resistor R11, while zero adjustment is facilitated by resistor R17.

The oil pressure gauge circuit operates by converting the mechanical pressure of the oil into an electrical signal. The sensor, typically a piezoresistive or capacitive type, generates a voltage that correlates with the oil pressure. This voltage is fed to resistor R1, which helps in scaling the signal to a suitable level for further processing.

The dual integrated circuits, IC1 and IC2, are configured to function as a two-digit digital voltmeter (DVM). These ICs convert the analog voltage signal into a digital format, allowing for clear and precise readings of the oil pressure. The multiplexed display is controlled by transistors Q1 and Q2, which select which digit to display at any given time, thus ensuring that the display is efficiently utilized and readable.

Powering the entire circuit, IC1 provides a stable +5 V supply, crucial for the operation of digital components and ensuring accurate readings. Calibration of the gauge is performed using resistor R11, which adjusts the gain of the circuit to match the expected pressure readings. Additionally, resistor R17 is utilized for zero adjustment, allowing the user to set the gauge to read zero when no pressure is applied, ensuring the accuracy of the gauge across its operational range.

Overall, this circuit design exemplifies an effective integration of analog and digital components to provide reliable oil pressure monitoring in automotive and industrial applications. This gauge uses a sensor in conjunction with R1 to develop a dc voltage proportional to oil pressure. IC1 and IC 2 form a two-digit DVM. Q1 and Q2 are display selectors for the multiplexed display. IC1 provides the necessary +5 V to the circuitry. Calibration is via Rll and zero adjust via R17. 🔗 External reference

The oil pressure gauge circuit operates by converting the mechanical pressure of the oil into an electrical signal. The sensor, typically a piezoresistive or capacitive type, generates a voltage that correlates with the oil pressure. This voltage is fed to resistor R1, which helps in scaling the signal to a suitable level for further processing.

The dual integrated circuits, IC1 and IC2, are configured to function as a two-digit digital voltmeter (DVM). These ICs convert the analog voltage signal into a digital format, allowing for clear and precise readings of the oil pressure. The multiplexed display is controlled by transistors Q1 and Q2, which select which digit to display at any given time, thus ensuring that the display is efficiently utilized and readable.

Powering the entire circuit, IC1 provides a stable +5 V supply, crucial for the operation of digital components and ensuring accurate readings. Calibration of the gauge is performed using resistor R11, which adjusts the gain of the circuit to match the expected pressure readings. Additionally, resistor R17 is utilized for zero adjustment, allowing the user to set the gauge to read zero when no pressure is applied, ensuring the accuracy of the gauge across its operational range.

Overall, this circuit design exemplifies an effective integration of analog and digital components to provide reliable oil pressure monitoring in automotive and industrial applications. This gauge uses a sensor in conjunction with R1 to develop a dc voltage proportional to oil pressure. IC1 and IC 2 form a two-digit DVM. Q1 and Q2 are display selectors for the multiplexed display. IC1 provides the necessary +5 V to the circuitry. Calibration is via Rll and zero adjust via R17. 🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713