diy dye laser

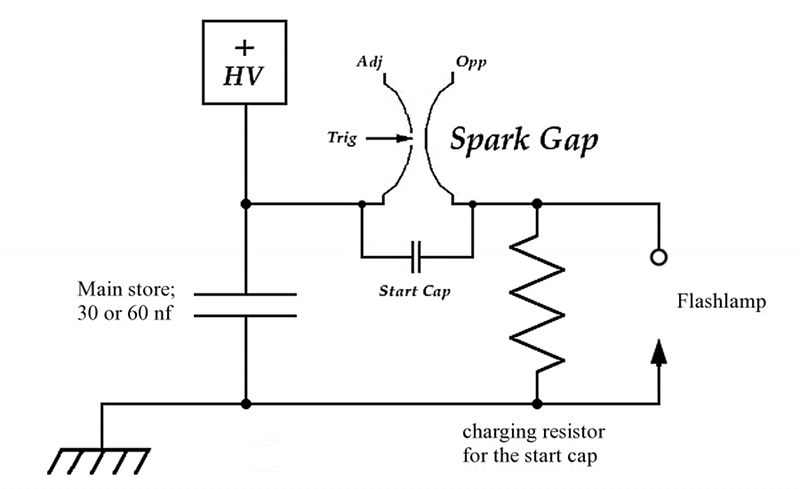

This page outlines the construction of a prototype dye laser designed for initial parameter testing. The primary objective is to determine whether a straightforward design can effectively threshold certain dyes with minimal input energy. Although the theoretical answer is affirmative, practical implementation may present challenges. The laser will operate near its efficiency margins, making any loss of efficiency difficult to mitigate. This preliminary design incorporates a commercial capacitor and a spark gap switch, both of which are intended for removal in future iterations. The final design will likely utilize a commercial flashlamp, as xenon is the most efficient emitter in the relevant wavelength regions for pumping organic dyes. Additionally, commercial laser mirrors may be employed. While some dye lasers have successfully utilized simpler, homebrewed mirrors, there is uncertainty regarding their ability to compensate for losses associated with materials like aluminum mirrors. Conversely, for those willing to work with longer wavelengths using red and near-infrared dyes, sputtered gold mirrors may prove effective, as a clean gold coating can achieve reflectance of at least 98% from the far red into the infrared, with a thinly-sputtered coating potentially serving as an output coupler. This laser operates at high voltages and employs capacitors capable of storing lethal energy amounts. It produces a laser beam that poses risks to eyes and skin and utilizes organic dyes, some of which are toxic, along with flammable organic solvents. Therefore, adequate safety precautions and appropriate safety equipment are essential, particularly with lasers involving high voltages and associated health or fire hazards. Previous experience includes building several lamp-pumped organic dye lasers and reviewing numerous technical articles on the subject, revealing certain characteristics that define viability. A reasonably high optical pump power is necessary, optimally achieved with a xenon-filled flashlamp, which can reach efficiencies exceeding 50% under ideal conditions. While not all emitted light will reach the dye solution, and not all light reaching the solution will be absorbed, these factors further enhance the attractiveness of xenon as a light source. High pump power is best realized by driving the lamp with a short electrical pulse. Many DIY enthusiasts err by attempting to operate lasers with large capacitors at low voltages. To generate a short pulse, it is crucial to minimize both the inductance and capacitance of the circuit driving the flashlamp; operating at low voltage complicates this. For instance, to deliver 25 Joules to a flashlamp using photoflash capacitors charged to 400 Volts, approximately 312.5 microfarads of capacitance is required. A rough estimation of the discharge speed of such a capacitor can be made by ignoring resistive effects; the Full Width at Half Maximum (FWHM) pulse width in seconds can be approximated as a constant multiplied by the square root of the product of inductance and capacitance, where inductance (L) is measured in henries and capacitance (C) in farads. Historical research on lamp-pumped dye lasers indicated that achieving a system inductance below 125 nanohenries is challenging; therefore, an inductance value of 150 nanohenries is used for calculations. This assumption is optimistic but consistent for preliminary evaluations. However, it is important to note that actual physical lamp driver circuits may not meet the predicted values due to higher inductance and resistive effects that this calculation does not account for.

The design of the dye laser focuses on optimizing the energy delivery system to ensure efficient operation. The use of a xenon flashlamp is critical, as it provides the necessary optical pump power for the dye solution. The circuit design must prioritize low inductance and capacitance to achieve the desired short pulsing effect. This involves careful selection of components and layout to minimize parasitic inductances, which can significantly impact performance. The choice of mirrors is also pivotal; while commercial mirrors are preferred for their reliability, experimentation with alternative mirror materials such as sputtered gold may yield favorable results for specific applications.

Safety considerations are paramount in the development of this dye laser, given the high voltages and toxic materials involved. Comprehensive safety protocols must be established, including the use of protective eyewear, appropriate shielding, and proper ventilation when working with organic solvents. The operational parameters of the laser should be meticulously monitored to prevent accidents and ensure safe handling of all components.

In conclusion, the construction of this prototype dye laser serves as a foundational step toward developing a more advanced system that can efficiently utilize organic dyes for laser applications. The insights gained from this initial design will inform future iterations, leading to improved performance and safety in laser technology.This page details the construction of a prototype dye laser that is intended for initial checking of some parameters — for example, I want to know whether a simple design will threshold easy dyes with minimal input energy. In principle, the answer is already known to be Yes ; but in practice it may not be so easy. The laser will be operating close to margins, and any sacrifice of efficiency will be difficult to work around. This preliminary design uses a commercial capacitor and a commercial spark gap switch, both of which I hope to eliminate in later designs. The machine that I`m working toward will almost certainly use a commercial flashlamp, though, because xenon is the most efficient emitter in the wavelength regions of interest for pumping organic dyes.

It will, very likely, also use commercial laser mirrors. Quite a few dye lasers have been operated with simpler mirrors, which could be homebrewed, but I am not at all certain that these machines will have enough oomph to overcome the losses inherent in [e. g. , aluminum] mirrors. OTOH, for those who are willing to work at long wavelengths, using red and NIR dyes, sputtered gold mirrors may be viable: a clean coating of gold has reflectance of at least 98% from the far red on out through the IR, and a thinly-sputtered coating could serve as an output coupler.

) This laser uses high voltages, and capacitors that can store lethal amounts of energy. It puts out a laser beam that can damage your eyes and skin, and it uses organic dyes, some of which are known to be quite toxic. It also uses flammable organic solvents. It is important to take adequate safety precautions and use appropriate safety equipment with any laser; but it is crucially important with lasers that involve high voltages and present a health and/or fire hazard!

I have built a number of lamp-pumped organic dye lasers in the past, and I have read a number of articles about dye lasers in technical journals. In the course of doing so, I`ve noticed some characteristics that appear to define viability. Reasonably high optical pump power is required, and that is best obtained with a xenon-filled flashlamp.

Xenon lamps can have efficiency as high as 50% or more under optimum circumstances. Granted, not all of the light can reach the dye solution, and not all of what reaches the dye solution can be absorbed by it; but those issues make xenon even more attractive as a source. High pump power is also best obtained by driving the lamp with a short electrical pulse. This is one place where many DIYers go astray, by attempting to run their lasers with large capacitors at relatively low voltages.

In order to create a short pulse you need to minimize both the inductance and the capacitance of the circuit that drives the flashlamp; operating at low voltage essentially makes that impossible. If you want to deliver 25 Joules to a flashlamp, and you are using photoflash capacitors that you charge to 400 Volts, you need 312.

5 f to store the energy. We can easily make a rough guess at how fast such a capacitor will discharge; ignoring resistive effects, the FWHM (Full Width at Half of the Maximum Amplitude) pulsewidth, in seconds, can be approximated as times the square root of the product of the inductance and the capacitance, where the inductance (L) is in henries, and the capacitance (C) is in farads. In an article on lamp-pumped dye lasers that was published some time ago, the authors determined that it is quite difficult to achieve system inductance of less than 125 nanohenry, so I am going to use 150 nh as the inductance value for this calculation.

That`s optimistic; but it is consistent, and will do for now. (Just don`t expect an actual physical lamp driver circuit to meet the number predicted by this calculation; any real circuit probably has higher inductance unless it is extremely well designed, and in addition there are resistive effects that this cal 🔗 External reference

The design of the dye laser focuses on optimizing the energy delivery system to ensure efficient operation. The use of a xenon flashlamp is critical, as it provides the necessary optical pump power for the dye solution. The circuit design must prioritize low inductance and capacitance to achieve the desired short pulsing effect. This involves careful selection of components and layout to minimize parasitic inductances, which can significantly impact performance. The choice of mirrors is also pivotal; while commercial mirrors are preferred for their reliability, experimentation with alternative mirror materials such as sputtered gold may yield favorable results for specific applications.

Safety considerations are paramount in the development of this dye laser, given the high voltages and toxic materials involved. Comprehensive safety protocols must be established, including the use of protective eyewear, appropriate shielding, and proper ventilation when working with organic solvents. The operational parameters of the laser should be meticulously monitored to prevent accidents and ensure safe handling of all components.

In conclusion, the construction of this prototype dye laser serves as a foundational step toward developing a more advanced system that can efficiently utilize organic dyes for laser applications. The insights gained from this initial design will inform future iterations, leading to improved performance and safety in laser technology.This page details the construction of a prototype dye laser that is intended for initial checking of some parameters — for example, I want to know whether a simple design will threshold easy dyes with minimal input energy. In principle, the answer is already known to be Yes ; but in practice it may not be so easy. The laser will be operating close to margins, and any sacrifice of efficiency will be difficult to work around. This preliminary design uses a commercial capacitor and a commercial spark gap switch, both of which I hope to eliminate in later designs. The machine that I`m working toward will almost certainly use a commercial flashlamp, though, because xenon is the most efficient emitter in the wavelength regions of interest for pumping organic dyes.

It will, very likely, also use commercial laser mirrors. Quite a few dye lasers have been operated with simpler mirrors, which could be homebrewed, but I am not at all certain that these machines will have enough oomph to overcome the losses inherent in [e. g. , aluminum] mirrors. OTOH, for those who are willing to work at long wavelengths, using red and NIR dyes, sputtered gold mirrors may be viable: a clean coating of gold has reflectance of at least 98% from the far red on out through the IR, and a thinly-sputtered coating could serve as an output coupler.

) This laser uses high voltages, and capacitors that can store lethal amounts of energy. It puts out a laser beam that can damage your eyes and skin, and it uses organic dyes, some of which are known to be quite toxic. It also uses flammable organic solvents. It is important to take adequate safety precautions and use appropriate safety equipment with any laser; but it is crucially important with lasers that involve high voltages and present a health and/or fire hazard!

I have built a number of lamp-pumped organic dye lasers in the past, and I have read a number of articles about dye lasers in technical journals. In the course of doing so, I`ve noticed some characteristics that appear to define viability. Reasonably high optical pump power is required, and that is best obtained with a xenon-filled flashlamp.

Xenon lamps can have efficiency as high as 50% or more under optimum circumstances. Granted, not all of the light can reach the dye solution, and not all of what reaches the dye solution can be absorbed by it; but those issues make xenon even more attractive as a source. High pump power is also best obtained by driving the lamp with a short electrical pulse. This is one place where many DIYers go astray, by attempting to run their lasers with large capacitors at relatively low voltages.

In order to create a short pulse you need to minimize both the inductance and the capacitance of the circuit that drives the flashlamp; operating at low voltage essentially makes that impossible. If you want to deliver 25 Joules to a flashlamp, and you are using photoflash capacitors that you charge to 400 Volts, you need 312.

5 f to store the energy. We can easily make a rough guess at how fast such a capacitor will discharge; ignoring resistive effects, the FWHM (Full Width at Half of the Maximum Amplitude) pulsewidth, in seconds, can be approximated as times the square root of the product of the inductance and the capacitance, where the inductance (L) is in henries, and the capacitance (C) is in farads. In an article on lamp-pumped dye lasers that was published some time ago, the authors determined that it is quite difficult to achieve system inductance of less than 125 nanohenry, so I am going to use 150 nh as the inductance value for this calculation.

That`s optimistic; but it is consistent, and will do for now. (Just don`t expect an actual physical lamp driver circuit to meet the number predicted by this calculation; any real circuit probably has higher inductance unless it is extremely well designed, and in addition there are resistive effects that this cal 🔗 External reference