DIY Full LED 600+ Lumens LED Headlight

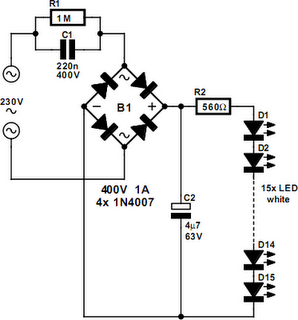

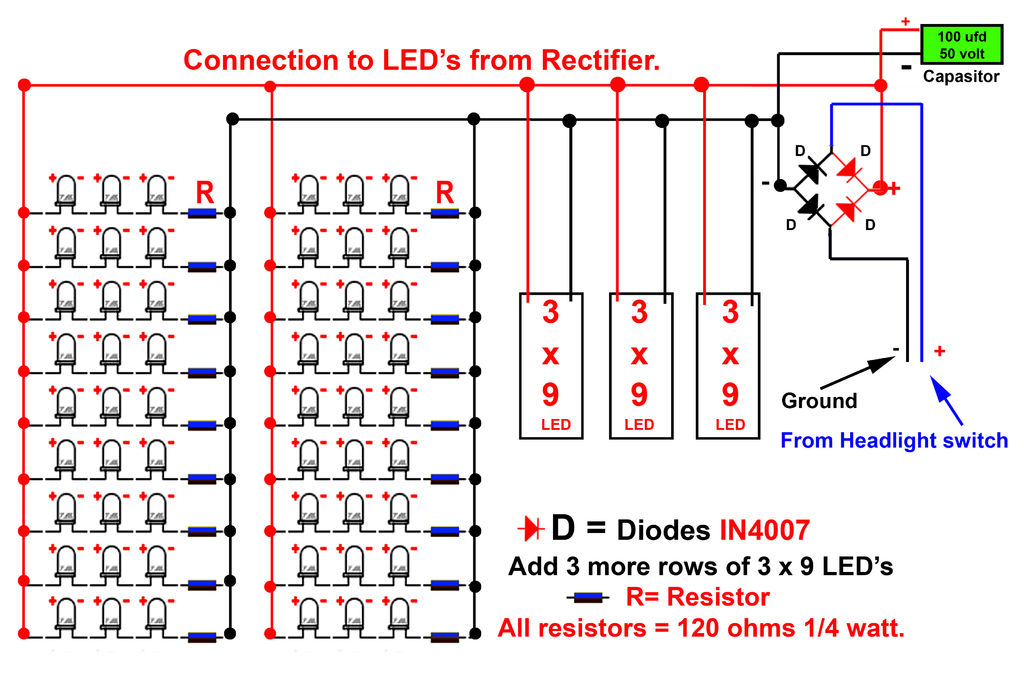

Gently bend the leads of the LEDs and, using the provided schematic circuit diagram, begin to solder. Once soldering is complete, it should...

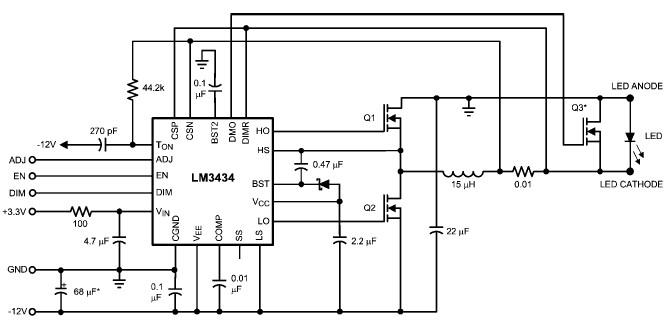

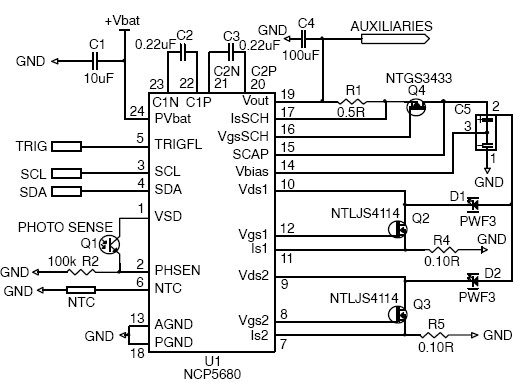

To successfully assemble the LED circuit, it is essential to follow a systematic approach. Start by preparing the workspace and ensuring all components are readily available. The schematic diagram serves as a crucial reference throughout the assembly process, illustrating the correct connections and orientations for each component.

Begin with the LEDs, which should be oriented correctly according to their anode and cathode leads. The anode is typically the longer lead and should connect to the positive voltage supply, while the cathode connects to the ground or negative side of the circuit. Gently bending the leads of the LEDs will facilitate easier insertion into the PCB or breadboard, ensuring a secure fit.

Before soldering, double-check the schematic to confirm that the LEDs are placed in the correct positions and that any necessary resistors are included in the circuit to limit current and prevent damage to the LEDs. The resistors should be chosen based on the specifications of the LEDs being used, considering their forward voltage and current ratings.

Once the components are positioned correctly, proceed to solder the connections. This involves heating the solder joint with a soldering iron until the solder flows and forms a solid connection. Care should be taken to avoid overheating the components, which could lead to damage. After soldering, inspect each joint for quality, ensuring that there are no cold solder joints or bridges between adjacent connections.

After completing the soldering process, it is advisable to test the circuit before finalizing the assembly. This can be done by applying power to the circuit and observing the LEDs for proper illumination. If any LEDs do not light up, it may indicate an issue with the connections or component orientation that requires troubleshooting.

In conclusion, meticulous attention to detail during the assembly of the LED circuit is crucial for ensuring functionality and reliability. Following the schematic diagram closely and adhering to proper soldering techniques will result in a successful circuit build.Now gently bend the leads of the LEDs and using the schematic circuit diagram given below begin to solder Once you finish soldering, it shoul.. 🔗 External reference

To successfully assemble the LED circuit, it is essential to follow a systematic approach. Start by preparing the workspace and ensuring all components are readily available. The schematic diagram serves as a crucial reference throughout the assembly process, illustrating the correct connections and orientations for each component.

Begin with the LEDs, which should be oriented correctly according to their anode and cathode leads. The anode is typically the longer lead and should connect to the positive voltage supply, while the cathode connects to the ground or negative side of the circuit. Gently bending the leads of the LEDs will facilitate easier insertion into the PCB or breadboard, ensuring a secure fit.

Before soldering, double-check the schematic to confirm that the LEDs are placed in the correct positions and that any necessary resistors are included in the circuit to limit current and prevent damage to the LEDs. The resistors should be chosen based on the specifications of the LEDs being used, considering their forward voltage and current ratings.

Once the components are positioned correctly, proceed to solder the connections. This involves heating the solder joint with a soldering iron until the solder flows and forms a solid connection. Care should be taken to avoid overheating the components, which could lead to damage. After soldering, inspect each joint for quality, ensuring that there are no cold solder joints or bridges between adjacent connections.

After completing the soldering process, it is advisable to test the circuit before finalizing the assembly. This can be done by applying power to the circuit and observing the LEDs for proper illumination. If any LEDs do not light up, it may indicate an issue with the connections or component orientation that requires troubleshooting.

In conclusion, meticulous attention to detail during the assembly of the LED circuit is crucial for ensuring functionality and reliability. Following the schematic diagram closely and adhering to proper soldering techniques will result in a successful circuit build.Now gently bend the leads of the LEDs and using the schematic circuit diagram given below begin to solder Once you finish soldering, it shoul.. 🔗 External reference