Drying the motor winding circuit current imbalance

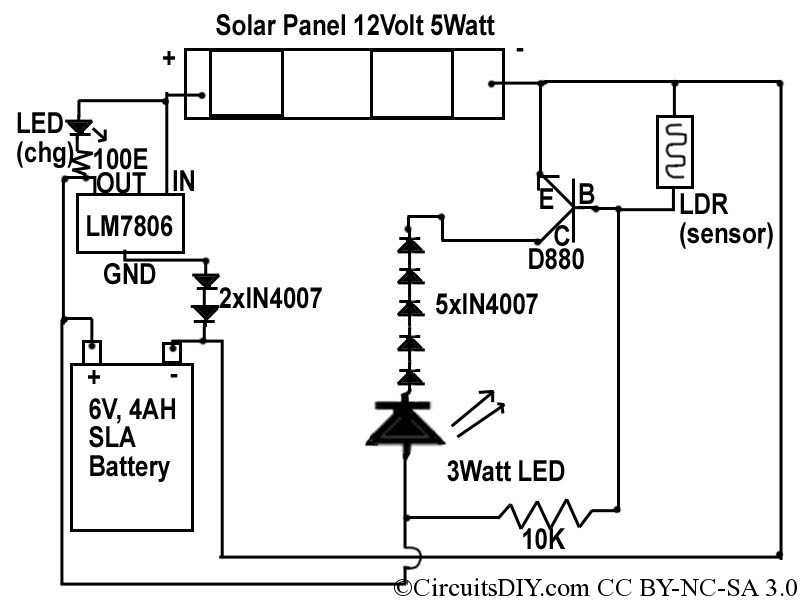

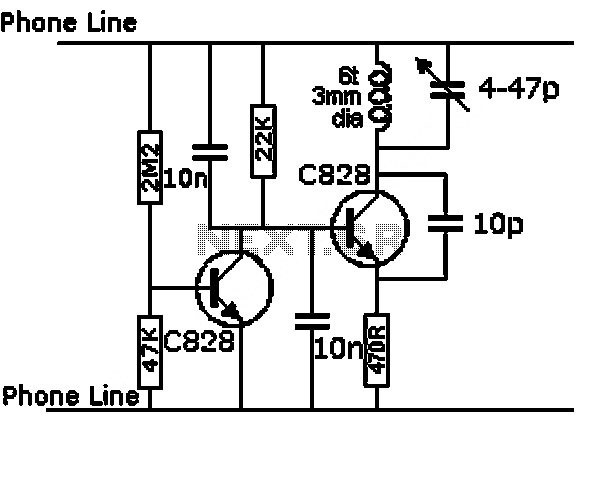

Below is a circuit diagram for detecting motor winding current imbalance during the drying process.

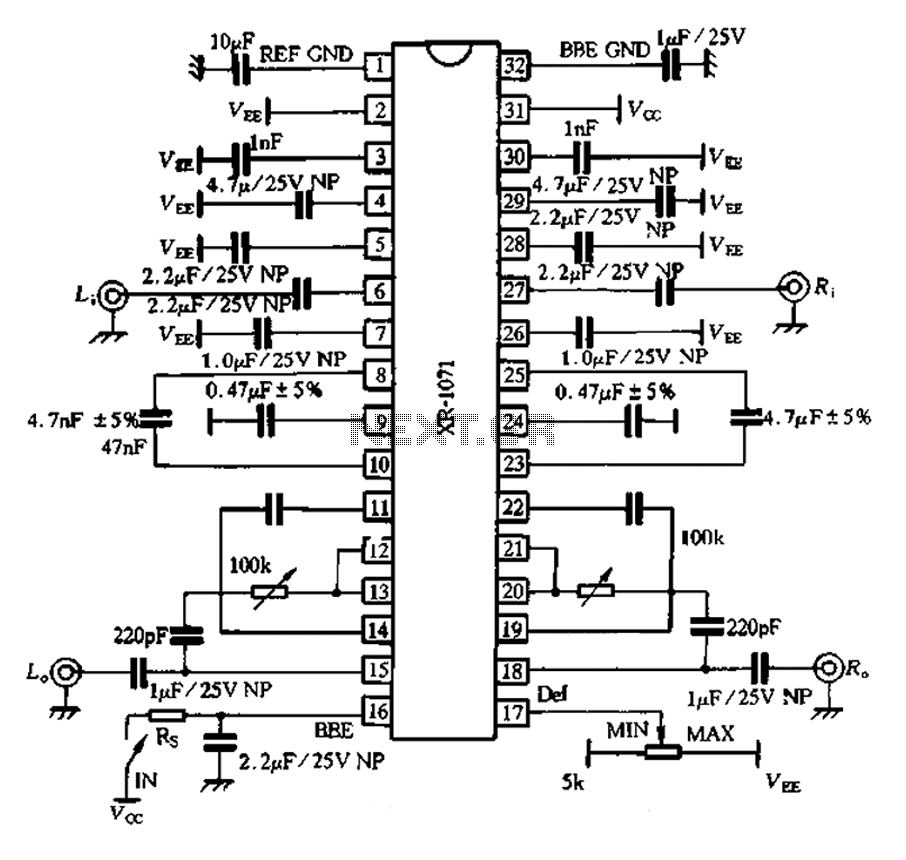

The circuit diagram is designed to monitor the current flowing through the windings of a motor used in drying applications. This imbalance detection is crucial for ensuring the motor operates efficiently and safely. The schematic typically includes current sensors, which can be Hall effect sensors or shunt resistors, connected to an operational amplifier (op-amp) configured as a differential amplifier. This setup allows for precise measurement of the current in each winding.

The output from the op-amp is then fed into a microcontroller or a comparator circuit. The microcontroller processes the current data and compares the values from the different windings. If an imbalance is detected, it can trigger an alarm or a shutdown mechanism to prevent damage to the motor.

Additionally, the circuit may include indicator LEDs to provide visual feedback on the status of the motor winding currents. A power supply circuit is also essential to ensure that all components receive the necessary voltage levels for operation.

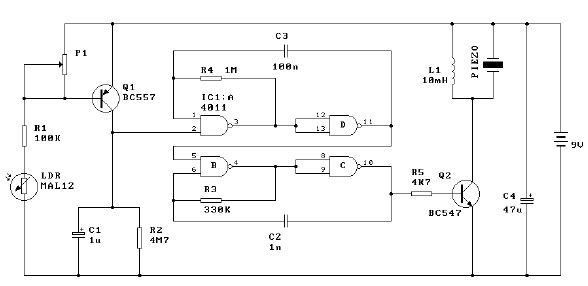

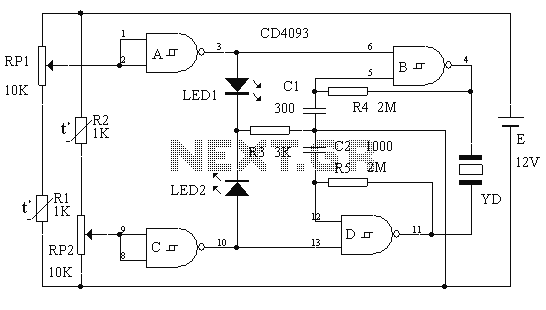

In summary, this motor winding current imbalance detection circuit is a critical component for maintaining the reliability and safety of drying motors, ensuring that they function within acceptable parameters and preventing potential failures due to uneven current distribution. Below is a circuit diagram of the motor winding current imbalance drying:

The circuit diagram is designed to monitor the current flowing through the windings of a motor used in drying applications. This imbalance detection is crucial for ensuring the motor operates efficiently and safely. The schematic typically includes current sensors, which can be Hall effect sensors or shunt resistors, connected to an operational amplifier (op-amp) configured as a differential amplifier. This setup allows for precise measurement of the current in each winding.

The output from the op-amp is then fed into a microcontroller or a comparator circuit. The microcontroller processes the current data and compares the values from the different windings. If an imbalance is detected, it can trigger an alarm or a shutdown mechanism to prevent damage to the motor.

Additionally, the circuit may include indicator LEDs to provide visual feedback on the status of the motor winding currents. A power supply circuit is also essential to ensure that all components receive the necessary voltage levels for operation.

In summary, this motor winding current imbalance detection circuit is a critical component for maintaining the reliability and safety of drying motors, ensuring that they function within acceptable parameters and preventing potential failures due to uneven current distribution. Below is a circuit diagram of the motor winding current imbalance drying: