ecm mic preamplifier

Microphone amplifier schematics that can be utilized with either Electret Condenser Microphone (ECM) inserts or dynamic inserts, constructed with discrete components. The process of creating a PCB is straightforward. Begin by using PCB design software such as Eagle to create the design. Print the design on photo paper or glossy paper using a laser printer. Adhere the printed design to the copper side of the PCB and apply heat using a hot iron plate. The ink will transfer onto the PCB, preparing it for the etching process. If a laser printer is unavailable, the design can be printed on standard paper and copied onto glossy paper at a local copy service.

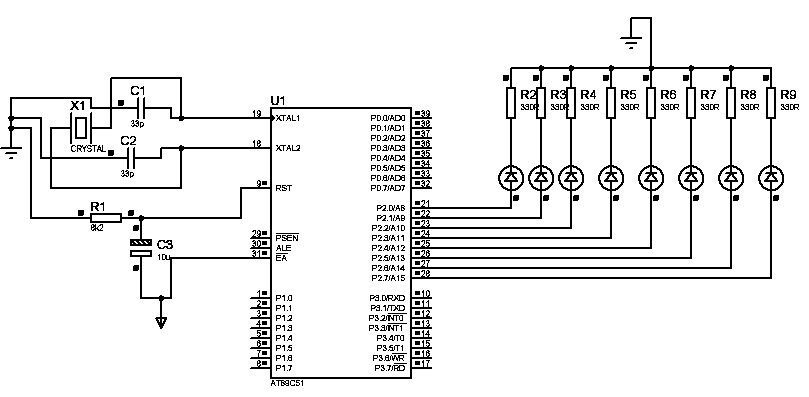

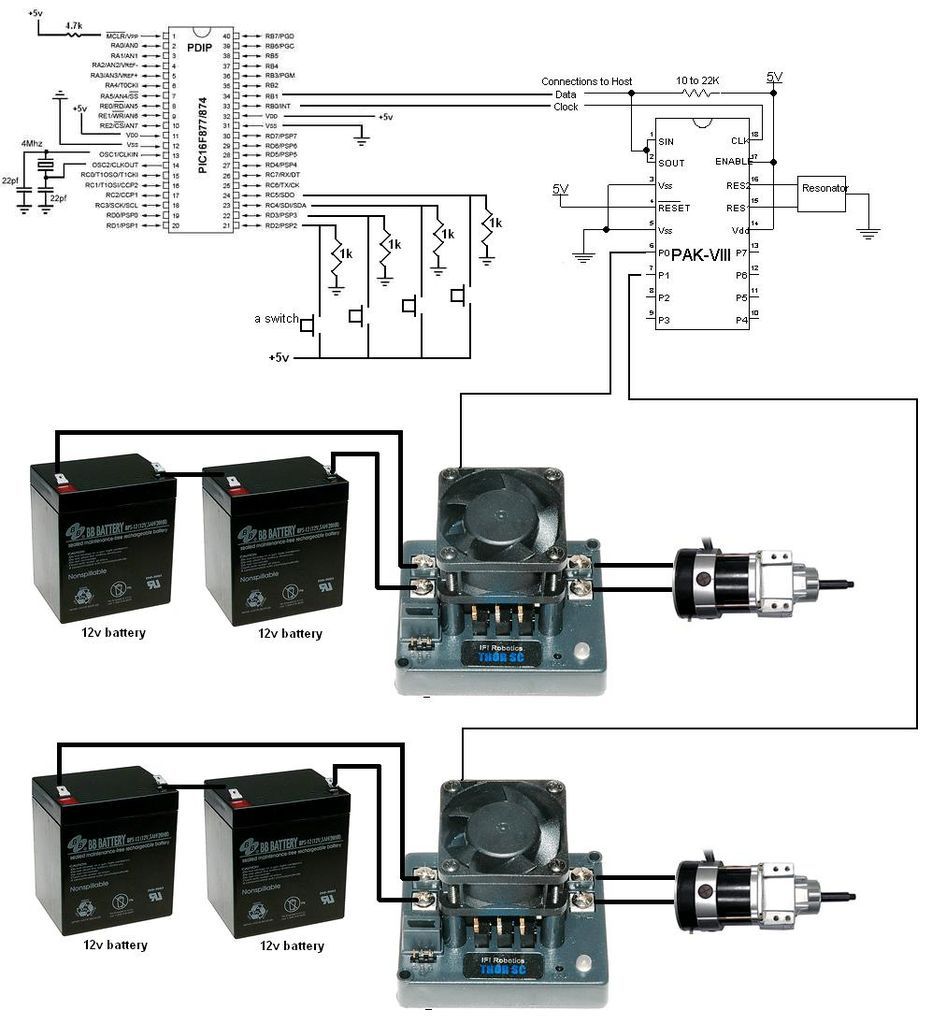

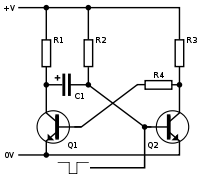

The microphone amplifier circuit is designed to amplify audio signals captured from either Electret Condenser Microphones (ECM) or dynamic microphones. The circuit typically includes a preamplifier stage, which is crucial for boosting the low-level signals generated by the microphones to a usable level for further processing.

The schematic may incorporate a transistor or operational amplifier as the main amplification component. In the case of an ECM, a biasing resistor is required to provide the necessary voltage for the microphone to operate. The output of the amplifier can be configured to drive further audio processing stages, such as filters or mixers, depending on the application.

The PCB design process involves several key steps. After creating the schematic using software like Eagle, the layout must be carefully designed to ensure minimal noise interference and optimal signal integrity. The traces should be wide enough to handle the current, and the placement of components should minimize the length of connections to reduce parasitic capacitance and inductance.

Once the design is finalized, printing on glossy paper allows for a clean transfer of the design onto the PCB. The use of a laser printer is recommended for its ability to produce a high-resolution image that adheres well during the heat transfer process. After adhering the design to the PCB, the heat application requires careful control to ensure that the ink transfers without damaging the board.

Following the transfer, the PCB is subjected to an etching process, typically using ferric chloride or a similar etching solution. This process removes the unprotected copper, leaving behind the desired circuit traces. After etching, the remaining ink can be removed, and the board can be drilled for component leads.

Finally, the components can be soldered onto the PCB, ensuring proper orientation and connection. The completed microphone amplifier circuit can then be tested for functionality, ensuring that it meets the desired specifications for audio amplification and quality.Microphone amplifier schematics that may be used with either Electret Condenser Microphone (ECM) inserts or dynamic inserts, made with discrete components : Make a PCB in very easy steps. ! Create your PCB design using PCB designer software like Eagle, print out your design on photo paper or glossy paper with laserjet printer.

Stick the prin ted design on the PCB (copper side) and then heat it using hot iron plate. The ink will stick on the PCB and it will be ready for etching process. Note: If you don`t have laserjet printer, then you can print the design on standard paper. Copy the printed design at Copy Service around your location (with glossy paper). 🔗 External reference

The microphone amplifier circuit is designed to amplify audio signals captured from either Electret Condenser Microphones (ECM) or dynamic microphones. The circuit typically includes a preamplifier stage, which is crucial for boosting the low-level signals generated by the microphones to a usable level for further processing.

The schematic may incorporate a transistor or operational amplifier as the main amplification component. In the case of an ECM, a biasing resistor is required to provide the necessary voltage for the microphone to operate. The output of the amplifier can be configured to drive further audio processing stages, such as filters or mixers, depending on the application.

The PCB design process involves several key steps. After creating the schematic using software like Eagle, the layout must be carefully designed to ensure minimal noise interference and optimal signal integrity. The traces should be wide enough to handle the current, and the placement of components should minimize the length of connections to reduce parasitic capacitance and inductance.

Once the design is finalized, printing on glossy paper allows for a clean transfer of the design onto the PCB. The use of a laser printer is recommended for its ability to produce a high-resolution image that adheres well during the heat transfer process. After adhering the design to the PCB, the heat application requires careful control to ensure that the ink transfers without damaging the board.

Following the transfer, the PCB is subjected to an etching process, typically using ferric chloride or a similar etching solution. This process removes the unprotected copper, leaving behind the desired circuit traces. After etching, the remaining ink can be removed, and the board can be drilled for component leads.

Finally, the components can be soldered onto the PCB, ensuring proper orientation and connection. The completed microphone amplifier circuit can then be tested for functionality, ensuring that it meets the desired specifications for audio amplification and quality.Microphone amplifier schematics that may be used with either Electret Condenser Microphone (ECM) inserts or dynamic inserts, made with discrete components : Make a PCB in very easy steps. ! Create your PCB design using PCB designer software like Eagle, print out your design on photo paper or glossy paper with laserjet printer.

Stick the prin ted design on the PCB (copper side) and then heat it using hot iron plate. The ink will stick on the PCB and it will be ready for etching process. Note: If you don`t have laserjet printer, then you can print the design on standard paper. Copy the printed design at Copy Service around your location (with glossy paper). 🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713