EGR 450 Manufacturing Controls Project

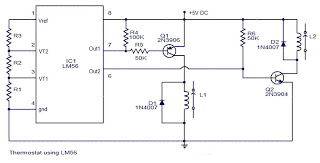

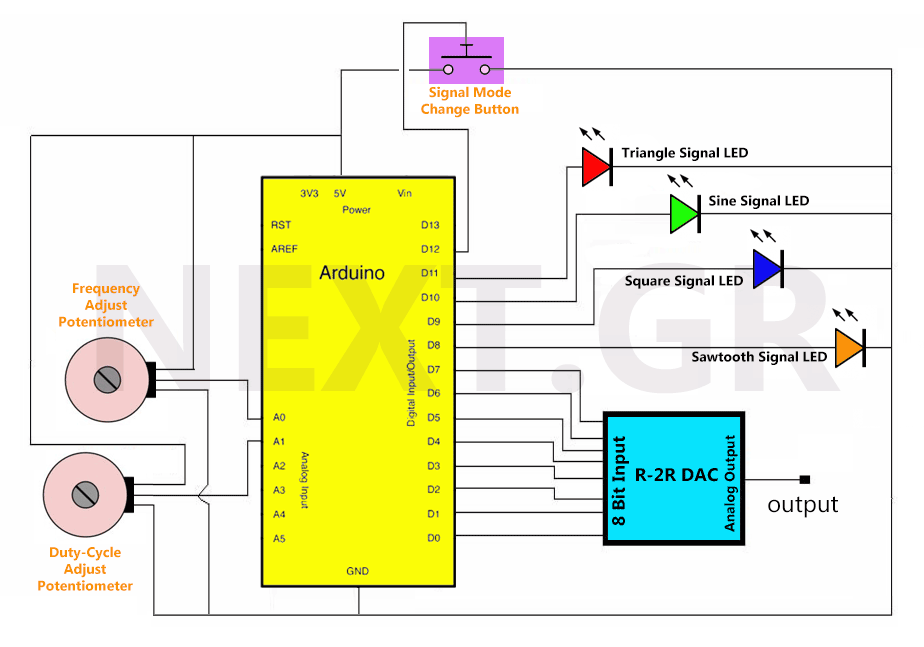

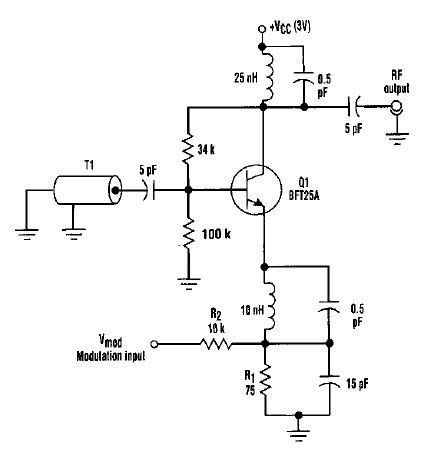

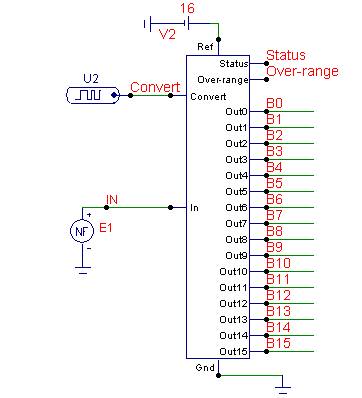

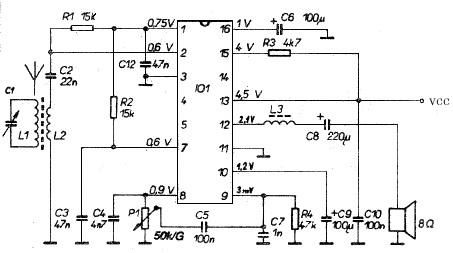

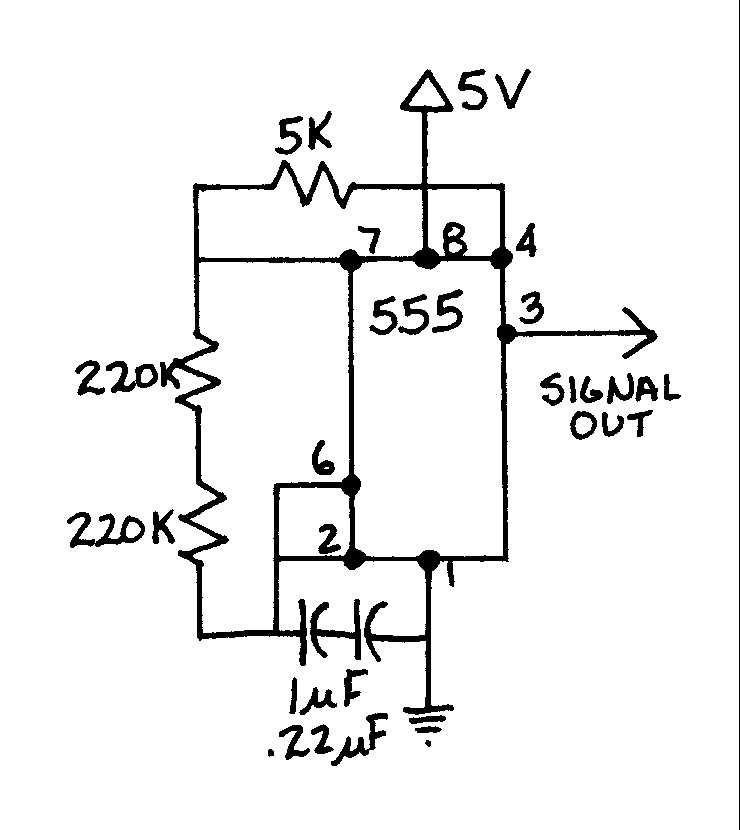

A timing and counting circuit utilizing integrated circuit chips with seven-segment LED displays is employed to show the current lap time, previous lap time, and total number of laps completed on a 1/64th-scale slot car racetrack. A switch activated by the car increments the lap counter, resets the lap timer, and updates the prior lap's time. Additionally, two switches are incorporated: one for power control and another for resetting the total lap count. This circuit was constructed using the BCD 0-99 Counter from the Engineer’s Mini-Notebook on Digital Logic Circuits by Forrest Mims III, available from Radio Shack. The circuit functions as the output driver for the LEDs displaying the timer and counter outputs. The schematic for this circuit is illustrated below as Figure 1. A 555 IC Timer generates the oscillating pulse input to the display circuit shown in Figure 1. The output pulse from pin 3 of the timer connects to pin 14 of the 74LS90 chip in the counter. This configuration is also connected to two additional identical circuits to display three digits. The circuit measures lap completion times ranging from 0.1 seconds to 99.9 seconds. The timer circuit schematic is depicted below as Figure 3. With the specified values, the timing circuit oscillates at 0.1 Hz, providing a display accurate to 0.1 seconds. To achieve a slower timer, capacitance must be increased, while decreasing capacitance speeds up the timer. However, faster timers become more challenging to calibrate accurately. A flip-flop circuit displays the time of the just completed lap. A 74175 IC placed between the 74LS90 and 74LS47 ICs ensures that the display shows only the completed time. When the car activates the switch, a signal is sent to the display to update the time. Due to the momentary delay, inverters are placed between the switch and the timer display to allow the completed lap time to update before resetting the current lap time. Without these inverters, the completed lap time resets to zero prematurely. The flip-flop schematic is shown below in Figure 4. Note: Only the modifications to the display driver circuit are illustrated; all other connections remain unchanged. This circuit was built from the 0-99 Second/Minute Timer found in the Engineer’s Mini-Notebook on Digital Logic Circuits by Forrest Mims III, available from Radio Shack. The input pulse for this circuit is provided by a switch integrated into the track. The pin securing the car to the track activates the switch, causing the timer to increment. This circuit determines the number of laps completed by a car. The circuit schematic is displayed below in Figure 5. The switch has been debounced to prevent multiple pulses. It activates upon initial contact and maintains that contact momentarily to avoid extra pulses. Multiple activations of the switch can inaccurately increment the timer and reset the previous lap time to zero. As this project comprises entirely TTL Integrated Circuits, the maximum input voltage for the circuits is 5 volts. An AC to DC converter sourced from Radio Shack powers the circuits. The selected converter was the Multi-Voltage 800mA Power Adapter, model number 273-1667, capable of supplying DC voltages of 3, 4, 5, 6, 7.5, 9, and 12 VDC, with a maximum current of 800mA. While this power supply offers a range of voltages, any equivalent supply producing 4.5 VDC to 6 VDC should suffice. After designing and testing the individual circuits, they were interconnected to form the complete system, which consists of three separate components.

The timing and counting circuit is designed to provide accurate lap timing and counting for a slot car racetrack. The use of integrated circuits, specifically the 74LS90 for counting and the 74LS47 for driving the seven-segment displays, ensures reliability and precision in lap time measurement. The 555 timer generates a stable oscillation that serves as the timing reference, allowing for fine-tuning of the lap timing accuracy. The incorporation of debouncing techniques for the switches is critical to prevent erroneous counts due to mechanical bounce, which is a common issue in switch-based designs.

The circuit's architecture allows for easy scalability; additional circuits can be added to extend functionality or increase display capabilities. The design also considers user interaction, with accessible switches for resetting and powering the system, enhancing usability during operation. The power supply choice is suitable for TTL logic levels, ensuring stable operation without risking damage to the integrated circuits.

Overall, this circuit design exemplifies a practical application of digital logic in a recreational setting, showcasing how integrated circuits can be effectively utilized to create an engaging and functional electronic system for timing and counting in slot car racing.A timing and counting circuit using integrated circuit chips with seven-segment LED displays is used to display current lap time, the previous lap time, and also the total number of laps completed on an assembled 1/64th-scale slot car racetrack. A switch contacted by the car will increment the lap counter, reset the lap timer, and also update the

prior lap ’s time. Two other switches will also be used, one to turn the power on and off, and another to reset the total number of laps completed. This circuit was built using the BCD 0-99 Counter in the Engineer ’s Mini-Notebook on Digital Logic Circuits by Forrest Mims III, available from Radio Shack.

This circuit serves as the output driver for the LED ’s used to display the timer and counter circuit outputs. The schematic for this circuit is shown below as Figure 1. A 555 IC Timer was used to create the oscillating pulse for the input to the display circuit shown in Figure 1.

The output pulse from pin 3 of the timer is wired to pin 14 of the 74LS90 chip in the counter. This circuit was also connected to two more identical circuits showing three digits. This circuit will be used to measure the time to complete a lap on the track ranging from 0. 1 seconds to 99. 9 seconds. The schematic for the timer circuit is shown below as Figure 3. Using the timer above with the shown values, the timing circuit oscillates at 0. 1 Hz giving us a timing display accurate to 0. 1 seconds. For a slower timer, the capacitance needs to be increased. To speed up the timer, the capacitance values need to be lowered. However, a faster timer will be harder to calibrate for accuracy. A flip-flop circuit was used to display the just completed lap ’s time. A 74175 IC inserted between the 74LS90 and 74LS47 IC ’s causes the display to only show the completed time. When the switch is activated by the car, it sends a signal to the display and updates the time. This takes a moment, so inverters are inserted between the switch and the timer display to allow the completed lap ’s time to update before the current lap time is reset.

Without the inverters, the completed lap ’s time sets to zero because the current lap time is reset to zero before the time is updated. The flip-flop schematic is shown below in Figure 4. Note: Only the changes made to the display driver circuit are shown, all other connections remain the same.

This circuit was built from the 0-99 Second/Minute Timer in the Engineer ’s Mini-Notebook on Digital Logic Circuits by Forrest Mims III available from Radio Shack. The input pulse for this circuit will be delivered by a switch that is built into the track. The pin that holds the car to the track will activate the switch causing the timer to increment. This circuit will be used to determine the number of laps that a car completes. The schematic for the circuit is shown below in Figure 5. The switch was debounced to prevent multiple pulses through the switch. The switch is activated on the initial contact and holds that contact momentarily to avoid any extra pulses.

If the switch is activated multiple times, it will increment the timer inaccurately, and will also cause the previous lap time to reset to zero. Since this project was constructed entirely with TTL Integrated Circuits, a maximum input voltage to the circuits was 5 volts.

To supply power to the circuits, an AC to DC converter was purchased at Radio Shack. The converter purchased was the Multi-Voltage 800mA Power Adapter, model number 273-1667. This Multi-Voltage adapter was capable of supplying DC voltages of 3, 4. 5 6, 7. 5 9 and 12VDC and up to 800mA current. Although this power supply has a range of available voltages, any comparable power supply producing 4. 5 VDC – 6 VDC should be suitable. Once all of the individual circuits were designed and tested by themselves, they were all connected together to create the complete system.

The system consists of three separate parts, 🔗 External reference

The timing and counting circuit is designed to provide accurate lap timing and counting for a slot car racetrack. The use of integrated circuits, specifically the 74LS90 for counting and the 74LS47 for driving the seven-segment displays, ensures reliability and precision in lap time measurement. The 555 timer generates a stable oscillation that serves as the timing reference, allowing for fine-tuning of the lap timing accuracy. The incorporation of debouncing techniques for the switches is critical to prevent erroneous counts due to mechanical bounce, which is a common issue in switch-based designs.

The circuit's architecture allows for easy scalability; additional circuits can be added to extend functionality or increase display capabilities. The design also considers user interaction, with accessible switches for resetting and powering the system, enhancing usability during operation. The power supply choice is suitable for TTL logic levels, ensuring stable operation without risking damage to the integrated circuits.

Overall, this circuit design exemplifies a practical application of digital logic in a recreational setting, showcasing how integrated circuits can be effectively utilized to create an engaging and functional electronic system for timing and counting in slot car racing.A timing and counting circuit using integrated circuit chips with seven-segment LED displays is used to display current lap time, the previous lap time, and also the total number of laps completed on an assembled 1/64th-scale slot car racetrack. A switch contacted by the car will increment the lap counter, reset the lap timer, and also update the

prior lap ’s time. Two other switches will also be used, one to turn the power on and off, and another to reset the total number of laps completed. This circuit was built using the BCD 0-99 Counter in the Engineer ’s Mini-Notebook on Digital Logic Circuits by Forrest Mims III, available from Radio Shack.

This circuit serves as the output driver for the LED ’s used to display the timer and counter circuit outputs. The schematic for this circuit is shown below as Figure 1. A 555 IC Timer was used to create the oscillating pulse for the input to the display circuit shown in Figure 1.

The output pulse from pin 3 of the timer is wired to pin 14 of the 74LS90 chip in the counter. This circuit was also connected to two more identical circuits showing three digits. This circuit will be used to measure the time to complete a lap on the track ranging from 0. 1 seconds to 99. 9 seconds. The schematic for the timer circuit is shown below as Figure 3. Using the timer above with the shown values, the timing circuit oscillates at 0. 1 Hz giving us a timing display accurate to 0. 1 seconds. For a slower timer, the capacitance needs to be increased. To speed up the timer, the capacitance values need to be lowered. However, a faster timer will be harder to calibrate for accuracy. A flip-flop circuit was used to display the just completed lap ’s time. A 74175 IC inserted between the 74LS90 and 74LS47 IC ’s causes the display to only show the completed time. When the switch is activated by the car, it sends a signal to the display and updates the time. This takes a moment, so inverters are inserted between the switch and the timer display to allow the completed lap ’s time to update before the current lap time is reset.

Without the inverters, the completed lap ’s time sets to zero because the current lap time is reset to zero before the time is updated. The flip-flop schematic is shown below in Figure 4. Note: Only the changes made to the display driver circuit are shown, all other connections remain the same.

This circuit was built from the 0-99 Second/Minute Timer in the Engineer ’s Mini-Notebook on Digital Logic Circuits by Forrest Mims III available from Radio Shack. The input pulse for this circuit will be delivered by a switch that is built into the track. The pin that holds the car to the track will activate the switch causing the timer to increment. This circuit will be used to determine the number of laps that a car completes. The schematic for the circuit is shown below in Figure 5. The switch was debounced to prevent multiple pulses through the switch. The switch is activated on the initial contact and holds that contact momentarily to avoid any extra pulses.

If the switch is activated multiple times, it will increment the timer inaccurately, and will also cause the previous lap time to reset to zero. Since this project was constructed entirely with TTL Integrated Circuits, a maximum input voltage to the circuits was 5 volts.

To supply power to the circuits, an AC to DC converter was purchased at Radio Shack. The converter purchased was the Multi-Voltage 800mA Power Adapter, model number 273-1667. This Multi-Voltage adapter was capable of supplying DC voltages of 3, 4. 5 6, 7. 5 9 and 12VDC and up to 800mA current. Although this power supply has a range of available voltages, any comparable power supply producing 4. 5 VDC – 6 VDC should be suitable. Once all of the individual circuits were designed and tested by themselves, they were all connected together to create the complete system.

The system consists of three separate parts, 🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713