Electrical circuit diagram cycled on and off timer

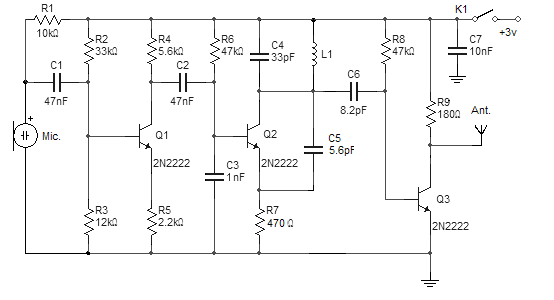

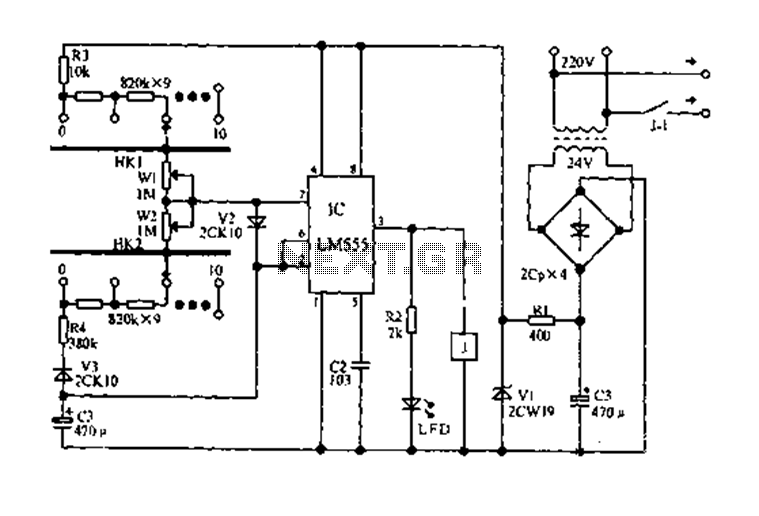

The circuit diagram for an electric start and stop timer is illustrated in the following cycle. It utilizes the LM555 integrated circuit configured as an adjustable duty cycle multivibrator. The circuit includes components C3, KH1, W1, KH2, and W2, which serve to adjust the stop time both coarsely and finely. When powered, current flows through R3 and the series resistance of HK1 and W1, charging capacitor C3. As a result, the output at pin 3 of the IC goes high, illuminating an LED and activating relay J, which connects the load. Once the voltage across C3 reaches two-thirds of the supply voltage, the IC toggles, causing the relay to release. Concurrently, capacitor C3 discharges through V3, R4, and the series resistance of HK2 and W2 to ground. When the voltage drops to one-third of the supply voltage, the IC toggles again, reactivating the relay. This process continues cyclically. Each block of HK1 and HK2 can adjust the delay by approximately 4.5 minutes, while the adjustment range for W1 and W2 is about 0-5 minutes.

The electric start and stop timer circuit employs the LM555 timer IC, which is renowned for its versatility in timing applications. In this configuration, the LM555 operates in astable mode, allowing it to generate a continuous square wave output. The timing intervals are determined by the values of the resistors (R3, HK1, HK2) and the capacitor (C3), which define the charging and discharging times.

The circuit begins with the application of power, initiating the charging process of capacitor C3 through the resistive components. As C3 charges, the voltage across it increases until it reaches the threshold level of 2/3 of the supply voltage. At this point, the LM555's internal flip-flop changes state, resulting in a high output signal at pin 3. This output signal is used to drive an LED indicator and activate relay J, which connects the load to the power source.

Simultaneously, the circuit begins the discharge phase of capacitor C3. This is facilitated through the discharge path involving V3, R4, and the resistances of HK2 and W2. The discharge occurs until the voltage across C3 falls to 1/3 of the supply voltage, at which point the LM555 toggles again, deactivating relay J and disconnecting the load.

The design incorporates adjustable elements (W1, W2) that allow for fine-tuning of the timing intervals. Each of these potentiometers can modify the resistance in the charging and discharging paths, effectively altering the time constants of the circuit. This flexibility enables a delay adjustment range of 0-5 minutes, while the overall coarse and fine adjustments provided by HK1 and HK2 can extend the delay period by approximately 4.5 minutes.

In summary, this timer circuit is capable of providing precise control over timing applications, making it suitable for various electronic projects where timed activation and deactivation of loads are required. The simplicity of the LM555 timer, combined with adjustable components, allows for a user-friendly experience in achieving desired timing outcomes.Electric start and stop the timer circuit diagram shown in the following cycle, LM555 adjustable duty cycle when the base integrated circuits multivibrator, the C3 charge-disch arge circuit in series KH1, W1, KH2, W2, respectively, as electrical open, stop time coarse and fine adjustment. When the circuit operates power through R3, HK1 series resistance and W1, V2 charging to C3, 3 feet high output of IC, LED lights, the relay J pull its contacts connected load.

When C3 voltage rises to 2/3 supply voltage, IC flip, relay releases. Meanwhile, C3 through V3, R4, 7 feet on HK2 series resistance W2 and IC-to-ground discharge. When the voltage drops to 1/3 C3 supply voltage, IC flip relay. So the cycle work. HK1, HK2 each block can increase or decrease the delay of 4.5 minutes, W1, W2 of the adjustment range of about 0-5 minutes.

The electric start and stop timer circuit employs the LM555 timer IC, which is renowned for its versatility in timing applications. In this configuration, the LM555 operates in astable mode, allowing it to generate a continuous square wave output. The timing intervals are determined by the values of the resistors (R3, HK1, HK2) and the capacitor (C3), which define the charging and discharging times.

The circuit begins with the application of power, initiating the charging process of capacitor C3 through the resistive components. As C3 charges, the voltage across it increases until it reaches the threshold level of 2/3 of the supply voltage. At this point, the LM555's internal flip-flop changes state, resulting in a high output signal at pin 3. This output signal is used to drive an LED indicator and activate relay J, which connects the load to the power source.

Simultaneously, the circuit begins the discharge phase of capacitor C3. This is facilitated through the discharge path involving V3, R4, and the resistances of HK2 and W2. The discharge occurs until the voltage across C3 falls to 1/3 of the supply voltage, at which point the LM555 toggles again, deactivating relay J and disconnecting the load.

The design incorporates adjustable elements (W1, W2) that allow for fine-tuning of the timing intervals. Each of these potentiometers can modify the resistance in the charging and discharging paths, effectively altering the time constants of the circuit. This flexibility enables a delay adjustment range of 0-5 minutes, while the overall coarse and fine adjustments provided by HK1 and HK2 can extend the delay period by approximately 4.5 minutes.

In summary, this timer circuit is capable of providing precise control over timing applications, making it suitable for various electronic projects where timed activation and deactivation of loads are required. The simplicity of the LM555 timer, combined with adjustable components, allows for a user-friendly experience in achieving desired timing outcomes.Electric start and stop the timer circuit diagram shown in the following cycle, LM555 adjustable duty cycle when the base integrated circuits multivibrator, the C3 charge-disch arge circuit in series KH1, W1, KH2, W2, respectively, as electrical open, stop time coarse and fine adjustment. When the circuit operates power through R3, HK1 series resistance and W1, V2 charging to C3, 3 feet high output of IC, LED lights, the relay J pull its contacts connected load.

When C3 voltage rises to 2/3 supply voltage, IC flip, relay releases. Meanwhile, C3 through V3, R4, 7 feet on HK2 series resistance W2 and IC-to-ground discharge. When the voltage drops to 1/3 C3 supply voltage, IC flip relay. So the cycle work. HK1, HK2 each block can increase or decrease the delay of 4.5 minutes, W1, W2 of the adjustment range of about 0-5 minutes.