Electrical control circuit plow

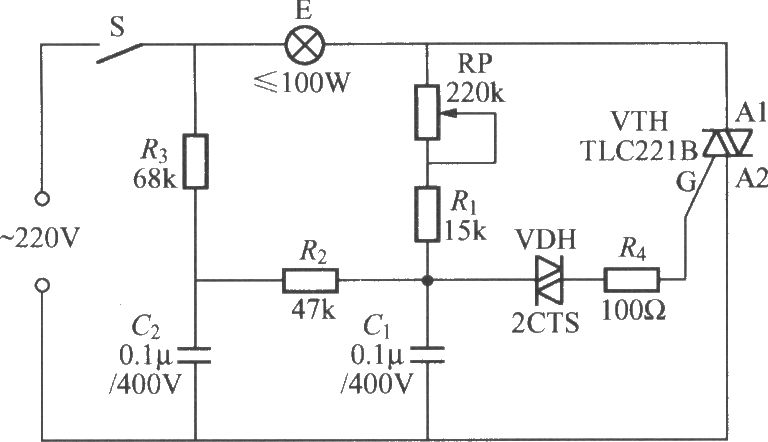

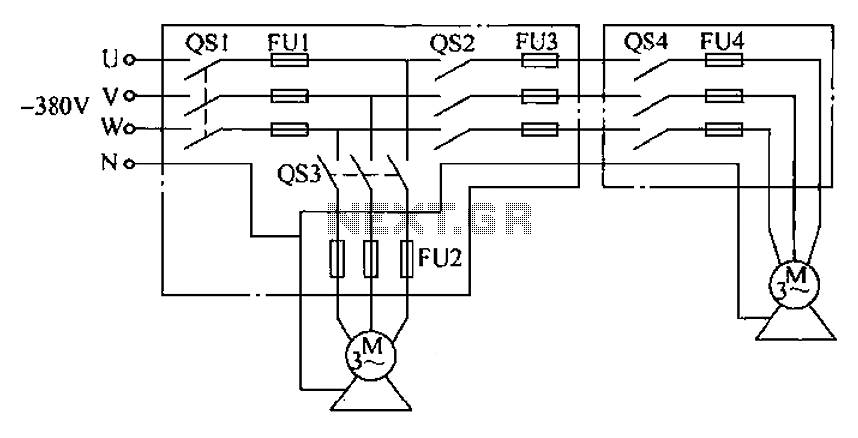

The agriculture and electrical power harrow plow power cord must consist of four rubber cables, with one core wire designated as the ground wire. The traction machine housing must be properly grounded. The two traction power machines are connected to the same distribution box on the farm via a four-core cable branch box, which supplies power to the two tractor power steering switches. As illustrated in Figure 8-9, the sub-branch box features three cable outlet holes, and the cables should be secured to these holes to prevent accidental disconnection. The power splitter box, which should be made of metal, must also be grounded and provide convenient connections for the two tractor positions. After use, the power cord should be promptly removed.

In agricultural applications, ensuring the safety and reliability of electrical connections is paramount. The design of the power cord system for the harrow plow incorporates four rubber cables to withstand harsh environmental conditions typically found in farming settings. Among these cables, one is specifically designated as a ground wire, which is critical for preventing electrical shock hazards and ensuring the safe operation of the equipment.

The traction machine housing must be grounded effectively to facilitate the safe dissipation of any electrical faults. This is achieved by connecting the ground wire to a suitable grounding point, which could be an earth stake or a metal structure that is in contact with the ground.

The power distribution system utilizes a four-core cable branch box that connects to the farm's main power supply. This branch box serves as a central hub from which power is distributed to two separate traction power machines. Each machine is equipped with a dedicated power steering switch, allowing for independent operation while ensuring that both machines can be powered from a single source.

The sub-branch box is designed with three outlet holes to accommodate the cables leading to the traction machines. To maintain a secure connection and prevent accidental disconnection, the cables should be properly tied to these holes. This precaution is essential, especially in dynamic agricultural environments where movement and vibrations are common.

The power splitter box, constructed from durable metal, not only provides structural integrity but also ensures that the system remains grounded. This grounding is vital for protecting the equipment and operators from potential electrical hazards. The design of the splitter box allows for easy and convenient connections, facilitating quick setup and adjustments between the two tractor positions.

Finally, it is important to emphasize the necessity of promptly removing the power cord after use. This practice not only prevents potential tripping hazards but also minimizes the risk of damage to the cables or the equipment, thereby enhancing the longevity and reliability of the electrical system in agricultural operations.Agriculture and electrical power harrow plow power cord must be used four rubber cable, wherein a core wire as a ground wire, traction machine housing must be grounded. Two tra ction power machine is a quote from the same distribution box in the farms out of a four-core cable branch box to the power supply, power points as a branch box into two (respectively to the two tractor power steering switch on). As shown in Figure 8-9. In sub- branch box, cable outlet opening three holes, the cable leads should tie the hole to prevent the plug off on their own.

Power splitter box support such as metal, must be grounded and provided convenient connection of two tractor position. After use, the power cord should be promptly removed.

In agricultural applications, ensuring the safety and reliability of electrical connections is paramount. The design of the power cord system for the harrow plow incorporates four rubber cables to withstand harsh environmental conditions typically found in farming settings. Among these cables, one is specifically designated as a ground wire, which is critical for preventing electrical shock hazards and ensuring the safe operation of the equipment.

The traction machine housing must be grounded effectively to facilitate the safe dissipation of any electrical faults. This is achieved by connecting the ground wire to a suitable grounding point, which could be an earth stake or a metal structure that is in contact with the ground.

The power distribution system utilizes a four-core cable branch box that connects to the farm's main power supply. This branch box serves as a central hub from which power is distributed to two separate traction power machines. Each machine is equipped with a dedicated power steering switch, allowing for independent operation while ensuring that both machines can be powered from a single source.

The sub-branch box is designed with three outlet holes to accommodate the cables leading to the traction machines. To maintain a secure connection and prevent accidental disconnection, the cables should be properly tied to these holes. This precaution is essential, especially in dynamic agricultural environments where movement and vibrations are common.

The power splitter box, constructed from durable metal, not only provides structural integrity but also ensures that the system remains grounded. This grounding is vital for protecting the equipment and operators from potential electrical hazards. The design of the splitter box allows for easy and convenient connections, facilitating quick setup and adjustments between the two tractor positions.

Finally, it is important to emphasize the necessity of promptly removing the power cord after use. This practice not only prevents potential tripping hazards but also minimizes the risk of damage to the cables or the equipment, thereby enhancing the longevity and reliability of the electrical system in agricultural operations.Agriculture and electrical power harrow plow power cord must be used four rubber cable, wherein a core wire as a ground wire, traction machine housing must be grounded. Two tra ction power machine is a quote from the same distribution box in the farms out of a four-core cable branch box to the power supply, power points as a branch box into two (respectively to the two tractor power steering switch on). As shown in Figure 8-9. In sub- branch box, cable outlet opening three holes, the cable leads should tie the hole to prevent the plug off on their own.

Power splitter box support such as metal, must be grounded and provided convenient connection of two tractor position. After use, the power cord should be promptly removed.

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713