Electronic Ignition Systems

With the exception of pilot-type water heaters and some smaller LP/Electric refrigerators, modern LP appliances in RVs are controlled by electronics.

Modern LP (liquefied petroleum) appliances utilized in recreational vehicles (RVs) have largely transitioned to electronic control systems, enhancing their efficiency and reliability. Unlike traditional appliances that rely on mechanical components or pilot lights for operation, these contemporary systems employ microcontrollers and sensors to manage various functions.

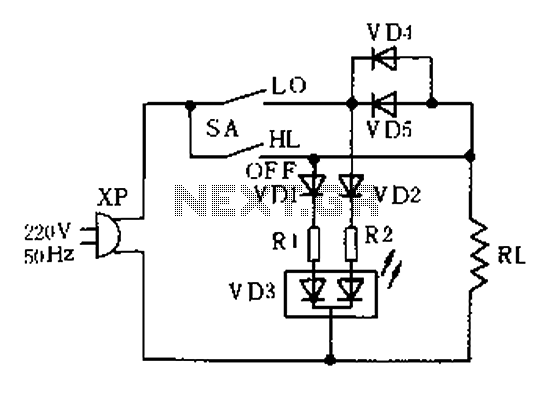

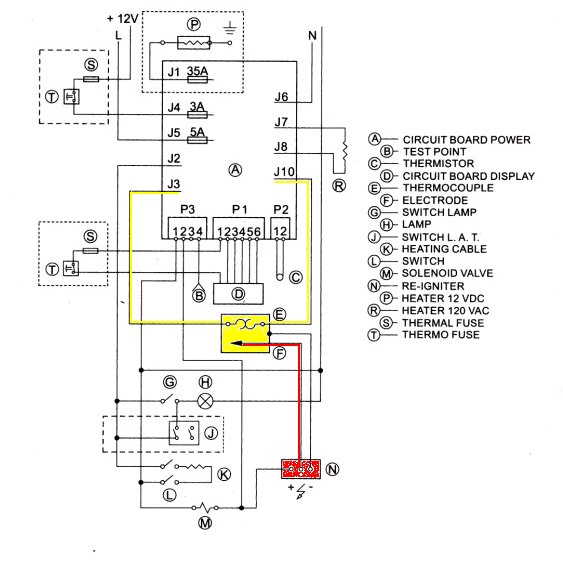

In RVs, electronic control systems facilitate the operation of appliances such as refrigerators, stoves, and heating units. The integration of electronics allows for features like automatic ignition, temperature regulation, and fault detection, which contribute to improved performance and user convenience. For instance, electronic ignition systems eliminate the need for a constant pilot flame, reducing gas consumption and increasing safety.

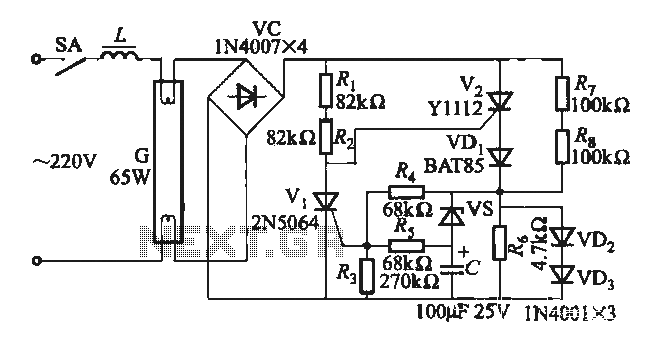

Moreover, the incorporation of sensors enables real-time monitoring of appliance performance. Temperature sensors can provide feedback to the control system, ensuring optimal operation of refrigeration units and preventing spoilage of perishable goods. Additionally, control units can communicate with other systems within the RV, such as battery management systems, to optimize energy use and extend battery life.

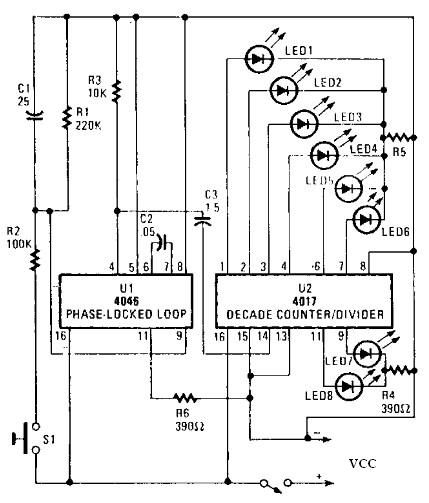

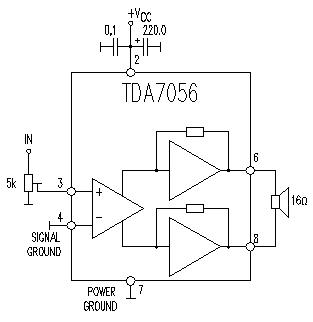

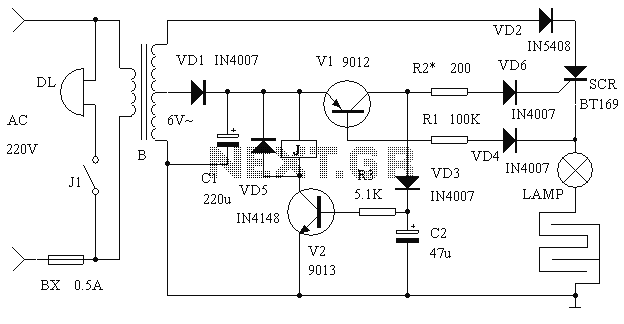

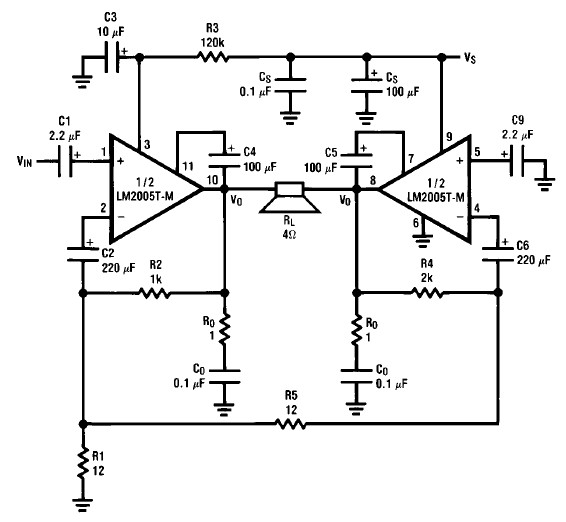

The design of these electronic circuits typically includes components such as microcontrollers, relays, and various input/output interfaces. These elements work together to create a cohesive system that can adapt to changing conditions and user demands. As RV technology continues to evolve, the reliance on electronic controls in LP appliances is expected to increase, driving innovations in both functionality and energy efficiency.With the exception of pilot type water heaters and some smaller LP/Electric refrigerators, modern LP appliances in RVs are controlled by electronics. 🔗 External reference

Modern LP (liquefied petroleum) appliances utilized in recreational vehicles (RVs) have largely transitioned to electronic control systems, enhancing their efficiency and reliability. Unlike traditional appliances that rely on mechanical components or pilot lights for operation, these contemporary systems employ microcontrollers and sensors to manage various functions.

In RVs, electronic control systems facilitate the operation of appliances such as refrigerators, stoves, and heating units. The integration of electronics allows for features like automatic ignition, temperature regulation, and fault detection, which contribute to improved performance and user convenience. For instance, electronic ignition systems eliminate the need for a constant pilot flame, reducing gas consumption and increasing safety.

Moreover, the incorporation of sensors enables real-time monitoring of appliance performance. Temperature sensors can provide feedback to the control system, ensuring optimal operation of refrigeration units and preventing spoilage of perishable goods. Additionally, control units can communicate with other systems within the RV, such as battery management systems, to optimize energy use and extend battery life.

The design of these electronic circuits typically includes components such as microcontrollers, relays, and various input/output interfaces. These elements work together to create a cohesive system that can adapt to changing conditions and user demands. As RV technology continues to evolve, the reliance on electronic controls in LP appliances is expected to increase, driving innovations in both functionality and energy efficiency.With the exception of pilot type water heaters and some smaller LP/Electric refrigerators, modern LP appliances in RVs are controlled by electronics. 🔗 External reference