Energy Saving Night Light circuit

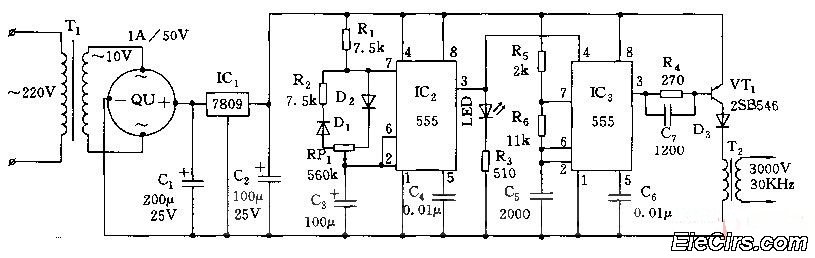

The lamps are usually used as ballast or electronic ballast inverter. Here it is used to reduce voltage capacitor reactance. Interesting is also the method of ignition of the auxiliary electrodes involved over 150 Ohm resistors. To start simply involve only one, but the lamp is switched on for longer blinks. Filament is not used and are short-circuited. The operation is relatively low-voltage fluorescent tubes, it looks like it worked pretty well and easy to drive on battery power. The drive would only have to load a relatively large supply voltage, or fluorescent lights. More: In a fluorescent lamp had capacity of 430 nF capacitor and the voltage was only 200 V. The second had a capacity of 470 nF and a voltage of 250 V. In any case, the capacitor should be at AC 250 V or 400 V DC at least I wonder how long used Capacitors can withstand before it breaks or shorted out and burns down the entire system?

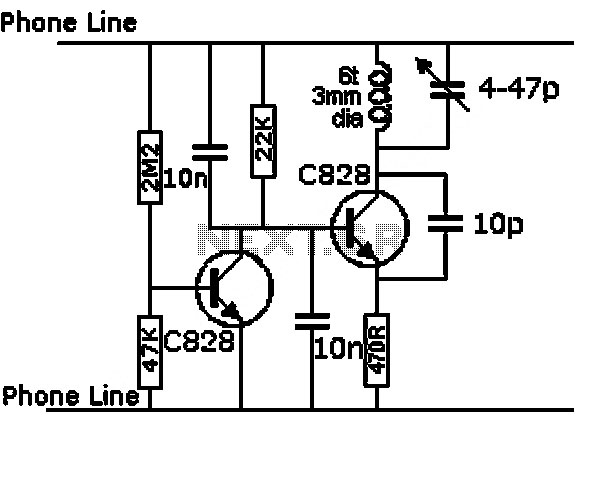

The circuit described involves the use of fluorescent lamps functioning as a ballast or electronic ballast inverter. This design utilizes capacitors to reduce voltage reactance, which is critical in managing the electrical characteristics of the circuit. The ignition process for the auxiliary electrodes is facilitated by the inclusion of resistors with a resistance of approximately 150 Ohms. The operational procedure indicates that only one resistor is necessary to initiate the lamp, although this may result in longer blinking periods before stable operation is achieved. Notably, the design omits the use of a filament, which is typically employed in traditional fluorescent lamps, and instead, the filament connections are short-circuited.

The circuit is designed for relatively low-voltage fluorescent tubes, making it suitable for operation with battery power. This is advantageous for portable applications where power supply constraints exist. The drive circuit must be capable of handling a considerable supply voltage to ensure the fluorescent lamps function effectively.

In the context of the capacitors used within this circuit, two examples are provided: one capacitor has a capacitance of 430 nF rated for 200 V, while the other has a capacitance of 470 nF rated for 250 V. It is essential that the capacitors are rated for at least AC 250 V or DC 400 V to ensure reliable operation and longevity. The durability of capacitors in this application is a critical consideration, as aged or degraded capacitors can lead to failure, potentially resulting in short circuits and subsequent damage to the entire system. Regular monitoring and replacement of these components may be necessary to maintain circuit integrity and performance. The lamps are usually used as ballast or electronic ballast inverter. Here it is used to reduce voltage capacitor reactance. Interesting is also the method of ignition of the auxiliary electrodes involved over 150 Ohm resistors. To start simply involve only one, but the lamp is switched on for longer blinks. Filament is not used and are short-circuited. The operation is relatively low-voltage fluorescent tubes, it looks like it worked pretty well and easy to drive on battery power.

The drive would only have to load a relatively large supply voltage, or fluorescent lights. In a fluorescent lamp had capacity of 430 nF capacitor and the voltage was only 200 V. The second had a capacity of 470 nF and a voltage of 250 V. In any case, the capacitor should be at AC 250 V or 400 V DC at least I wonder how long used Capacitors can withstand before it breaks or shorted out and burns down the entire system? 🔗 External reference

The circuit described involves the use of fluorescent lamps functioning as a ballast or electronic ballast inverter. This design utilizes capacitors to reduce voltage reactance, which is critical in managing the electrical characteristics of the circuit. The ignition process for the auxiliary electrodes is facilitated by the inclusion of resistors with a resistance of approximately 150 Ohms. The operational procedure indicates that only one resistor is necessary to initiate the lamp, although this may result in longer blinking periods before stable operation is achieved. Notably, the design omits the use of a filament, which is typically employed in traditional fluorescent lamps, and instead, the filament connections are short-circuited.

The circuit is designed for relatively low-voltage fluorescent tubes, making it suitable for operation with battery power. This is advantageous for portable applications where power supply constraints exist. The drive circuit must be capable of handling a considerable supply voltage to ensure the fluorescent lamps function effectively.

In the context of the capacitors used within this circuit, two examples are provided: one capacitor has a capacitance of 430 nF rated for 200 V, while the other has a capacitance of 470 nF rated for 250 V. It is essential that the capacitors are rated for at least AC 250 V or DC 400 V to ensure reliable operation and longevity. The durability of capacitors in this application is a critical consideration, as aged or degraded capacitors can lead to failure, potentially resulting in short circuits and subsequent damage to the entire system. Regular monitoring and replacement of these components may be necessary to maintain circuit integrity and performance. The lamps are usually used as ballast or electronic ballast inverter. Here it is used to reduce voltage capacitor reactance. Interesting is also the method of ignition of the auxiliary electrodes involved over 150 Ohm resistors. To start simply involve only one, but the lamp is switched on for longer blinks. Filament is not used and are short-circuited. The operation is relatively low-voltage fluorescent tubes, it looks like it worked pretty well and easy to drive on battery power.

The drive would only have to load a relatively large supply voltage, or fluorescent lights. In a fluorescent lamp had capacity of 430 nF capacitor and the voltage was only 200 V. The second had a capacity of 470 nF and a voltage of 250 V. In any case, the capacitor should be at AC 250 V or 400 V DC at least I wonder how long used Capacitors can withstand before it breaks or shorted out and burns down the entire system? 🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713