Fire Fighting Robot

When determining how to navigate the robot through the house, the designers recognized the necessity for precise movement to avoid colliding with walls and incurring penalties. To achieve the required movement precision, it was decided that the robot would employ stepper motors. The primary advantage of stepper motors is their ability to turn a specific number of degrees with each step. A four-phase stepper motor consists of four coils that, when energized in a specific sequence, create a rotating magnetic field that subsequently rotates a set of permanent magnets. These permanent magnets are attached to a rotor, which drives an output shaft. By pulsing the coils in a defined sequence, either clockwise or counterclockwise movement can be achieved. A change in the coil states (for example, transitioning from state 2 to state 3) results in a single step of the motor shaft. Direction is easily controlled by executing the sequence forward or backward. It is important to note that coils A and A' are always oppositely charged, as are coils B and B'. By inverting the signals sent to coils A and B, the corresponding signals A' and B' can be generated. Consequently, only two control lines are necessary to set the motor into any of the four possible states. Although this is a significant consideration for certain applications, the controller implemented in this design has an adequate number of lines to control each coil. Additionally, since two coils are always energized at any given time, the rotor is maintained in position by the two magnetic fields, preventing slippage even when the motor is not in motion. This characteristic is another advantage of stepper motors. The stepper motors utilized for this project were salvaged from surplus Epson printers. These steppers are designed to provide 1.8 degrees per step (or 200 steps per revolution) and deliver sufficient torque. However, the current requirements of most motors exceed what a digital output can provide. To address this, a transistor circuit is required to drive the motor coils. The circuit used to drive the motor coils functions by receiving a digital input from the microcontroller. This signal is sent to an optoisolator to separate the low-voltage, low-current microcontroller from potentially hazardous signals in the motor driver circuit. The optoisolator enables the 68HC12 to control the motors without any direct connection to the driver circuit. The output side of the optoisolator then drives the base of the TIP112 driver transistor. Like the stepper motors, the TIP112 transistors were also salvaged from Epson printers. The TIP112 power transistors can supply up to 50 watts of power, which is more than adequate to drive the stepper motor coils. When the microcontroller outputs a digital low signal (logic 0), the output side of the optoisolator behaves as an open circuit (i.e., no current flows into the collector). The remaining current path is then from Vcc through a pull-up resistor into the base of the TIP112 driver transistor, effectively turning the transistor on and allowing current to flow from collector to emitter. Consequently, current flows from the 7.2V battery, through the motor coil, into the collector of the TIP112, and to the emitter ground. Therefore, when a logic 0 is sent from the 68HC12 to a specific driver circuit, the corresponding coil becomes energized. Conversely, when the microcontroller outputs a digital high signal (logic 1), current will flow from collector to emitter in the output of the optoisolator, inhibiting current from entering the base of the driver transistor, thus turning it off.

The robot's movement system relies heavily on the precise control offered by stepper motors. The four-phase stepper motor's operation hinges on energizing the coils in a specific sequence, which can be meticulously controlled via a microcontroller. The design allows for smooth and accurate movement by enabling the robot to navigate tight spaces without collision. The use of optoisolators not only protects the microcontroller from high voltages but also ensures that the control signals are clean and reliable.

The circuit design for controlling the stepper motors incorporates multiple TIP112 transistors, ensuring that each motor coil receives adequate power. By employing a pull-up resistor, the circuit can effectively manage the state of the TIP112 transistors, allowing for precise energization of the coils based on the microcontroller's output. This setup is crucial for maintaining the integrity of the robot's navigation system, especially in environments where precision is paramount.

Overall, the integration of stepper motors, a well-designed control circuit, and the use of salvaged components from Epson printers demonstrates an efficient approach to building a robot capable of navigating complex environments while maintaining the necessary precision in movement.When deciding how to move the robot through the house, the designers realized that precision movement would be necessary in order to avoid touching the walls and receiving penalties. In order to achieve the required precision in movement, it was decided that the robot would utilize stepper motors.

The main benefit of stepper motors is that they are able to turn a specific number of degrees for every step. A four phase stepper motor has four coils that, when energized in a specific sequence, rotate a driving magnetic field which, consequently, rotates a set of permanent magnets. These permanent magnets are attached to a rotor which drives an output shaft. Thus, by pulsing the coils in a certain sequence, a clockwise or counterclockwise movement can be attained.

A change in the coil states (ie. changing from state 2 to state 3 as shown above) results in a single step of the motor shaft. Direction is easily controlled by running through the above sequence either forward or backward. It should also be noted that the coils A and A` are always oppositely charged, as are coils B and B`. By inverting the signals going to coils A and B, the corresponding signals A` and B` can be attained.

Thus, only two control lines are required to place the motor into any one of the 4 possible states. Even though this is an important consideration for certain applications, the controller used in this implementation has a sufficient number of lines to control each coil. Furthermore, because two of the coils are always energized at any given time, the rotor is held into place by the two magnetic fields and hence will not easily slip - even when the motor is not turning.

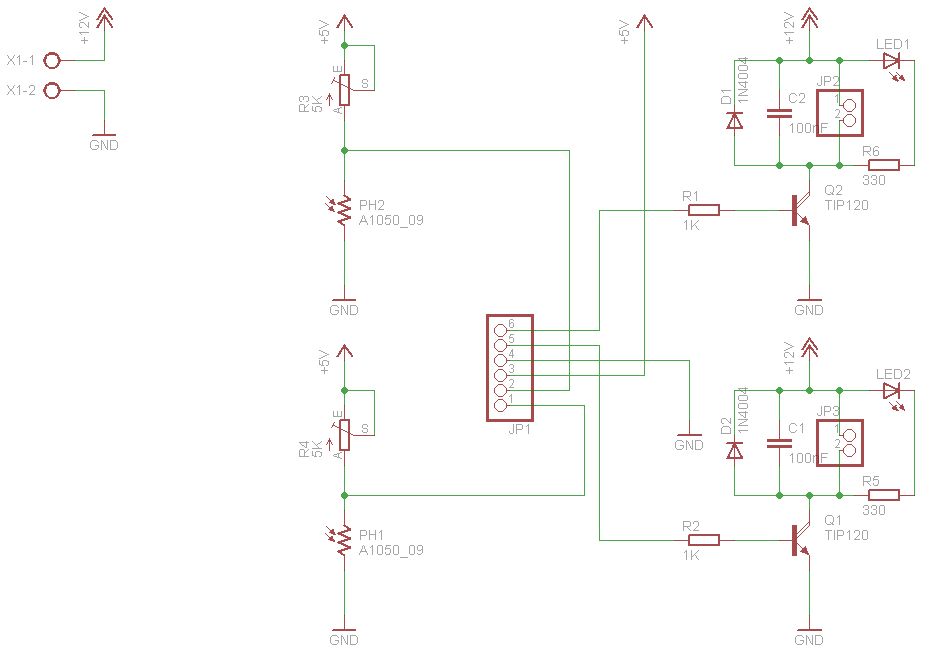

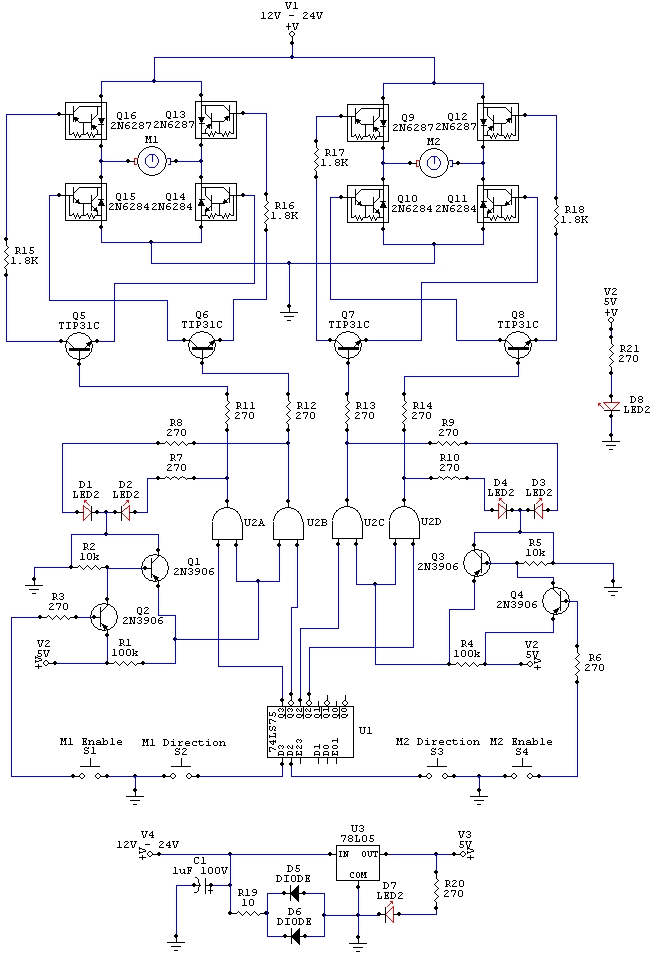

This is another benefit of stepper motors. Figure 2 provides an internal diagram of a typical four phase stepper motor. The stepper motors used for this project were salvaged from surplus Epson printers. The steppers are designed to provide 1. 8 degrees per step (or 200 steps per revolution) and supply a sufficient amount of torque. However, the current requirements of almost any motor are more than a digital output can provide. Because of this requirement, a transistor circuit is needed to drive the motor coils. The circuit shown in Figure 3 is used to drive the motor coils. Because there are a total of eight motor coils in the robot, eight of these circuits are needed. The circuit functions by receiving a digital input from the microcontroller. This signal is fed to an optoisolator in order to separate the low-voltage, low-current microcontroller from potentially dangerous signals in the motor driver circuit. In other words, the optoisolator allows the 68HC12 to control the motors without any physical connection to the driver circuit.

The output side of the optoisolator then drives the base of the TIP112 driver transistor. Just as the stepper motors were, the TIP112 transistors were salvaged from the Epson printers. The TIP112 power transistors are able to supply 50 watts of power, which is more than sufficient to drive the stepper motor coils. When the microcontroller outputs a digital low signal (logic 0), the output side of the optoisolator acts as an open circuit (ie.

no current flows into the collector). The remaining current path is then from Vcc through the pull-up resistor and into the base of the TIP112 driver transistor. This effectively turns the transistor on so that current can flow from collector to emitter. Clearly, current will flow from the 7. 2V battery, through the motor coil, into the collector of the TIP112, and to the emitter ground. Hence, when a logic 0 is sent from the 68HC12 to a given driver circuit, the corresponding coil will become energized.

Inversely, when the microcontroller outputs a digital high signal (logic 1), current will flow from collector to emitter in the output of the optoisolator. This will restrict current from flowing into the base of the driver transistor - causing it to be 🔗 External reference

The robot's movement system relies heavily on the precise control offered by stepper motors. The four-phase stepper motor's operation hinges on energizing the coils in a specific sequence, which can be meticulously controlled via a microcontroller. The design allows for smooth and accurate movement by enabling the robot to navigate tight spaces without collision. The use of optoisolators not only protects the microcontroller from high voltages but also ensures that the control signals are clean and reliable.

The circuit design for controlling the stepper motors incorporates multiple TIP112 transistors, ensuring that each motor coil receives adequate power. By employing a pull-up resistor, the circuit can effectively manage the state of the TIP112 transistors, allowing for precise energization of the coils based on the microcontroller's output. This setup is crucial for maintaining the integrity of the robot's navigation system, especially in environments where precision is paramount.

Overall, the integration of stepper motors, a well-designed control circuit, and the use of salvaged components from Epson printers demonstrates an efficient approach to building a robot capable of navigating complex environments while maintaining the necessary precision in movement.When deciding how to move the robot through the house, the designers realized that precision movement would be necessary in order to avoid touching the walls and receiving penalties. In order to achieve the required precision in movement, it was decided that the robot would utilize stepper motors.

The main benefit of stepper motors is that they are able to turn a specific number of degrees for every step. A four phase stepper motor has four coils that, when energized in a specific sequence, rotate a driving magnetic field which, consequently, rotates a set of permanent magnets. These permanent magnets are attached to a rotor which drives an output shaft. Thus, by pulsing the coils in a certain sequence, a clockwise or counterclockwise movement can be attained.

A change in the coil states (ie. changing from state 2 to state 3 as shown above) results in a single step of the motor shaft. Direction is easily controlled by running through the above sequence either forward or backward. It should also be noted that the coils A and A` are always oppositely charged, as are coils B and B`. By inverting the signals going to coils A and B, the corresponding signals A` and B` can be attained.

Thus, only two control lines are required to place the motor into any one of the 4 possible states. Even though this is an important consideration for certain applications, the controller used in this implementation has a sufficient number of lines to control each coil. Furthermore, because two of the coils are always energized at any given time, the rotor is held into place by the two magnetic fields and hence will not easily slip - even when the motor is not turning.

This is another benefit of stepper motors. Figure 2 provides an internal diagram of a typical four phase stepper motor. The stepper motors used for this project were salvaged from surplus Epson printers. The steppers are designed to provide 1. 8 degrees per step (or 200 steps per revolution) and supply a sufficient amount of torque. However, the current requirements of almost any motor are more than a digital output can provide. Because of this requirement, a transistor circuit is needed to drive the motor coils. The circuit shown in Figure 3 is used to drive the motor coils. Because there are a total of eight motor coils in the robot, eight of these circuits are needed. The circuit functions by receiving a digital input from the microcontroller. This signal is fed to an optoisolator in order to separate the low-voltage, low-current microcontroller from potentially dangerous signals in the motor driver circuit. In other words, the optoisolator allows the 68HC12 to control the motors without any physical connection to the driver circuit.

The output side of the optoisolator then drives the base of the TIP112 driver transistor. Just as the stepper motors were, the TIP112 transistors were salvaged from the Epson printers. The TIP112 power transistors are able to supply 50 watts of power, which is more than sufficient to drive the stepper motor coils. When the microcontroller outputs a digital low signal (logic 0), the output side of the optoisolator acts as an open circuit (ie.

no current flows into the collector). The remaining current path is then from Vcc through the pull-up resistor and into the base of the TIP112 driver transistor. This effectively turns the transistor on so that current can flow from collector to emitter. Clearly, current will flow from the 7. 2V battery, through the motor coil, into the collector of the TIP112, and to the emitter ground. Hence, when a logic 0 is sent from the 68HC12 to a given driver circuit, the corresponding coil will become energized.

Inversely, when the microcontroller outputs a digital high signal (logic 1), current will flow from collector to emitter in the output of the optoisolator. This will restrict current from flowing into the base of the driver transistor - causing it to be 🔗 External reference