heroine clock

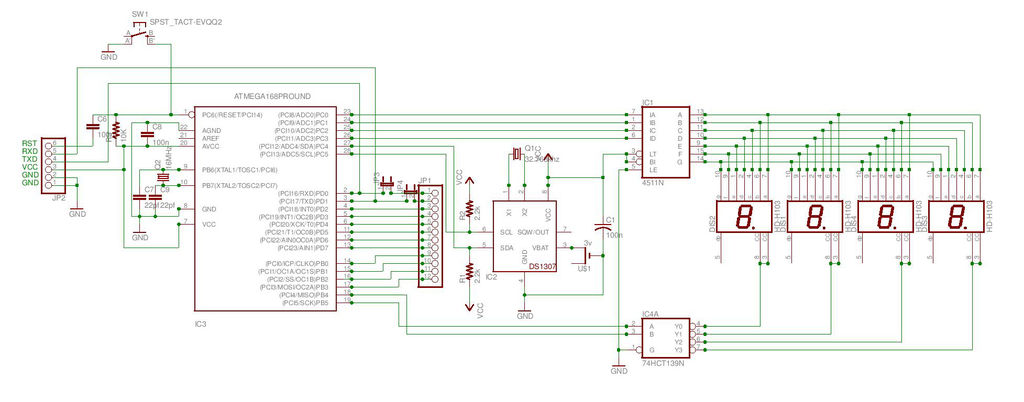

This 6" x 18" clock requires 52 light sources and aims to enable individuals to read the time without glasses. For 25 years, the search for sufficiently large clocks that could be seen without glasses proved fruitless, leading to the necessity of placing multiple clocks throughout a cramped apartment. An exploration into detecting overheating components without direct contact with the fingers led to the discovery of a small thermistor capable of quickly measuring electronic parts. By integrating a microprocessor and display, this thermistor could function as a highly sensitive thermometer. To make the large clock affordable, it was proposed to use the thermometer as a secondary function. The thermoclock is designed to operate on 6V battery power or AC power with automatic battery recharging, with an estimated cost of $40, primarily due to the expense of LEDs and the microprocessor. Testing involved acquiring two high-cost LEDs, which were found to be significantly cheaper in Hong Kong. After various experiments, the optimal configuration was determined to be with both LEDs facing each other, maintaining intact lenses. The challenge of permanently mounting the LEDs was addressed by utilizing fiberglass as a heat-resistant soldering surface, leading to the fabrication of 27 small fiberglass pieces for LED mounting. The process generated considerable dust, complicating the working environment. It was discovered that using PNP transistors as current sinks proved more efficient than NPN transistors as current sources, allowing for the switching of a 2.2V LED with a 5V supply. Other projects at Heroine Virtual necessitated thermometer testing to progress, shifting focus to the HeroineClock. Funding for the LEDs posed a significant challenge, as the high-brightness test LEDs were costly. The economic downturn in 2004 caused an increase in the price of imported semiconductor devices. An innovative design for a lightning bolt suitable for laminating rocket engines and power supplies was also developed. The largest LED manufacturing project in the U.S. since 0 A.D. commenced, involving extensive labor to assemble the electronics. Upon initial power-up, all LEDs illuminated, and layers of wax paper, tinted foil, and acrylic plastic were applied to create a smooth clock face, which would otherwise be excessively bright without the tinted foil. However, the high power consumption of the LEDs rendered battery operation nearly impossible. Additionally, concerns arose regarding the microcontroller's memory capacity, as the 68HC11 lacked sufficient flash memory for the intended operations. Alternative microcontrollers were sourced to mitigate potential memory limitations, with the 44-pin PLCCs offering 14k of flash, significantly exceeding the 68HC11's capacity. Unfortunately, these microcontrollers lacked serial port programming, necessitating a bit-banging approach across several pins for configuration.

The design of the clock integrates multiple components and systems to achieve both timekeeping and temperature measurement functionalities. The clock employs 52 LEDs, strategically arranged to provide visibility from a distance without the need for corrective lenses. The thermistor, a critical component, allows for rapid temperature readings, enhancing the clock's utility as a thermometer. The power supply system is designed to accommodate both a 6V battery and AC power, ensuring versatility in operation and enabling automatic recharging of the battery.

The use of PNP transistors as current sinks optimizes power efficiency, allowing for effective control of the LEDs. This choice facilitates the operation of the LEDs at higher voltages, thereby enhancing brightness without compromising functionality. The mounting of the LEDs on fiberglass pieces ensures stability and heat resistance, crucial for long-term operation.

The clock's aesthetic appeal is enhanced by the layering of materials that provide a polished finish while mitigating glare from the bright LEDs. The integration of wax paper, tinted foil, and acrylic plastic not only improves the visual quality but also contributes to the durability of the clock.

Despite the challenges posed by the high power consumption of the LEDs and potential memory limitations of the microcontroller, the design demonstrates a commitment to innovation and functionality. The use of alternative microcontrollers with greater memory capacity offers a pathway to overcoming these limitations, ensuring that the clock can perform its intended functions effectively. The project represents a significant advancement in clock design, merging practicality with modern electronic capabilities.This 6" x 18" clock needs 52 light sources. It may one day allow humans to know the time without glasses. For 25 years we searched for clocks big enough to be see without glasses. No large clock existed commercially so our only resort was to have clocks everywhere in the dumpy apartment. Then one day, was looking for ways to see if c omponents were overheating without burning fingers. Commercial thermometers are too slow and expensive. Discovered a tiny thermister which could measure electronic parts quickly. With a microprocessor and a display this thermister could be a highly sensitive thermometer. A large clock wouldn`t be affordable if it couldn`t perform some other function, however. Using the thermometer as the clock`s second function would make it affordable. The thermoclock would need to run on 6V battery power or AC power with automatic battery recharging. Looking at $40 for this thermoclock. Most of the cost is in the LEDs and microprocessor. Got 2 of the world`s most expensive LEDs for testing. Radioshack charges $2 for a single LED which is only $0. 10 in Hong Kong. After several tests including shaving off the lenses, the best position had both LED`s facing each other and the lenses left intact. The key was figuring out how to permanently mount LEDs in that position. Discovered fiberglass is resistant enough to heat to be used as a soldering surface. Lacking the money to make a fiberglass sheet for the entire clock, cut out 27 small fiberglass pieces to mount LEDs on.

Went through a few respirators grinding those out. So much dust is coating the apartment now that breathing is like falling in love with members. Unlike french fry grease or cigarette smoke, fiberglass dust doesn`t make you cough right away. You can breathe it for several minutes before dying. Discovered using PNP transistors as current sinks is far more efficient than using NPN transistors as current sources. The switching voltage needs not be limited to the voltage of the gadget being powered with a PNP transistor, so switching a 2.

2V LED with 5V is possible. Some other projects at Heroine Virtual reached a point where they required themometer testing to go any further so now our full attention is on HeroineClock. Finding enough money for the LEDs was a real problem. Though bright, the test LED`s were at the upper end of LED brightness. No-one in the US has LED`s that bright for less than $2. The dollar collapsed in 2004 and semiconductor devices, which all must be imported, have become super expensive.

Speaking of heroines, finally put together a heroine lightning bolt suitable for laminating rocket engines and power supplies and making clock icons out of. The largest LED manufacturing project in the US since 0 A. D. took place. An army of American welders went through a massive amount of wire and solder, erecting this monster of electronics.

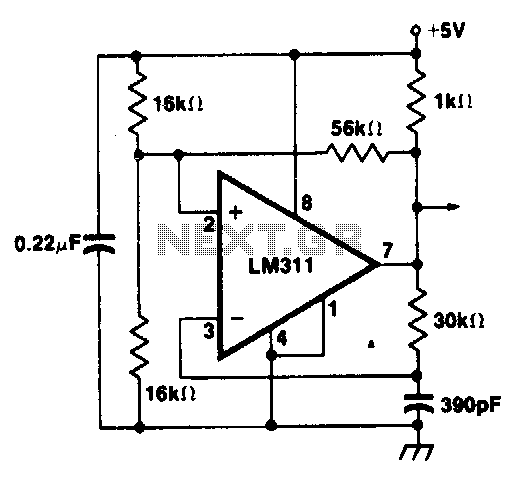

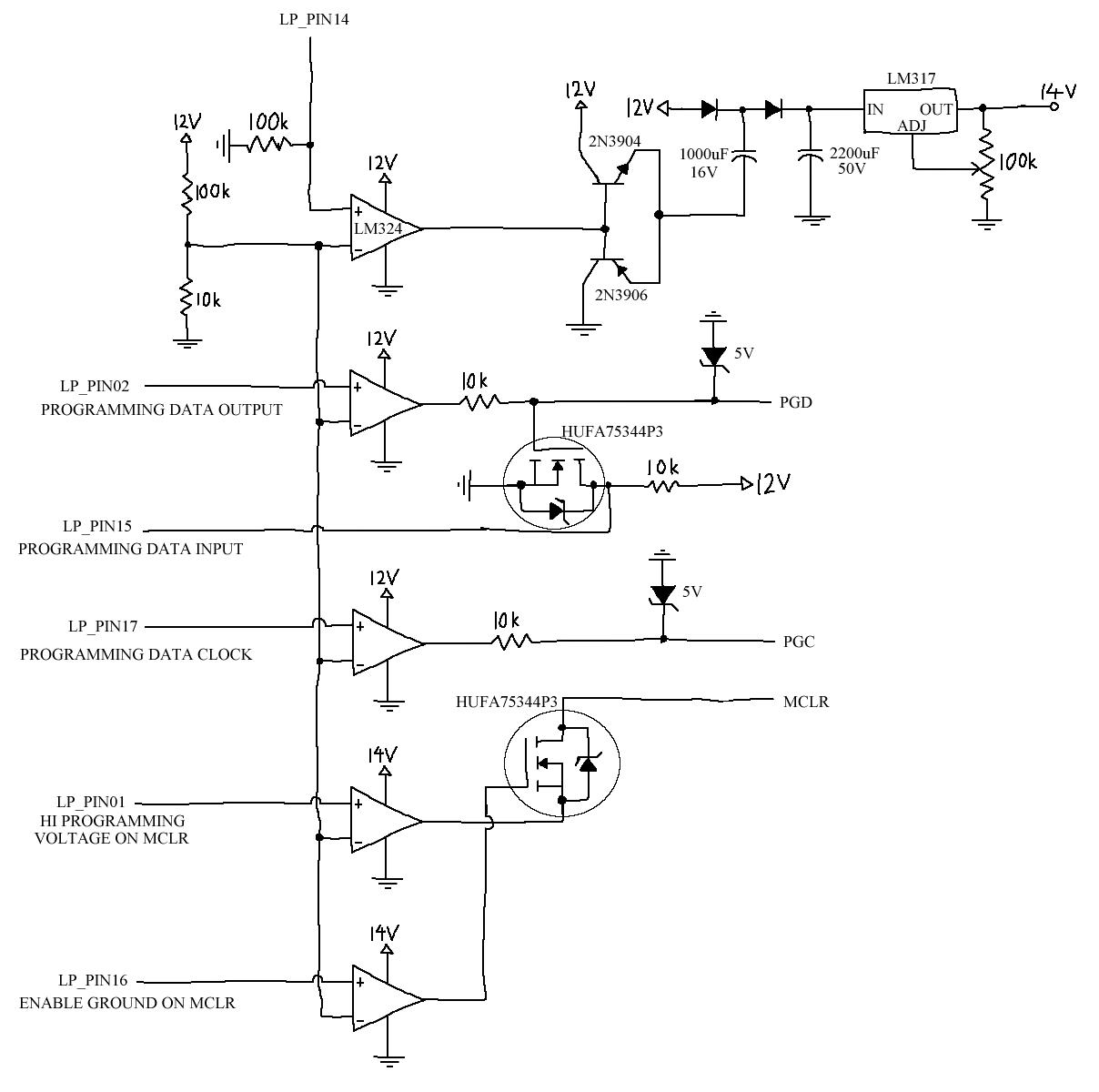

Aren`t you glad you don`t need to build this. All the LEDs fire up for the first time. On top of the LEDs, we`ve layered wax paper, tinted foil, and acrylic plastic, which gives the clock a nice smooth face despite the uneaven wood. Without the tinted foil HeroineClock is blinding. Unfortunately these LEDs use an enourmous amount of power. The dream of running HeroineClock on batteries is all but impossible. Secondly it doesn`t look like the microcontroller has enough memory to do everything. Not sure how they intend the 68hc11 to be used since none of them have more than 512 bytes of flash. We obtained some free alternative microcontrollers before beginning HeroineClock. These were just in case the 68HC11 ran out of memory like it did. Even the 18 pin DIPs have 3x the memory of the 68HC11. The 44 pin PLCCs used in HeroineClock have 14k of flash, 28 times the memory of the 68HC11. There`s no way these`ll run out of memory. Unfortunately these microcontrollers have no serial port programming. Instead you must bit bang several pins fr 🔗 External reference

The design of the clock integrates multiple components and systems to achieve both timekeeping and temperature measurement functionalities. The clock employs 52 LEDs, strategically arranged to provide visibility from a distance without the need for corrective lenses. The thermistor, a critical component, allows for rapid temperature readings, enhancing the clock's utility as a thermometer. The power supply system is designed to accommodate both a 6V battery and AC power, ensuring versatility in operation and enabling automatic recharging of the battery.

The use of PNP transistors as current sinks optimizes power efficiency, allowing for effective control of the LEDs. This choice facilitates the operation of the LEDs at higher voltages, thereby enhancing brightness without compromising functionality. The mounting of the LEDs on fiberglass pieces ensures stability and heat resistance, crucial for long-term operation.

The clock's aesthetic appeal is enhanced by the layering of materials that provide a polished finish while mitigating glare from the bright LEDs. The integration of wax paper, tinted foil, and acrylic plastic not only improves the visual quality but also contributes to the durability of the clock.

Despite the challenges posed by the high power consumption of the LEDs and potential memory limitations of the microcontroller, the design demonstrates a commitment to innovation and functionality. The use of alternative microcontrollers with greater memory capacity offers a pathway to overcoming these limitations, ensuring that the clock can perform its intended functions effectively. The project represents a significant advancement in clock design, merging practicality with modern electronic capabilities.This 6" x 18" clock needs 52 light sources. It may one day allow humans to know the time without glasses. For 25 years we searched for clocks big enough to be see without glasses. No large clock existed commercially so our only resort was to have clocks everywhere in the dumpy apartment. Then one day, was looking for ways to see if c omponents were overheating without burning fingers. Commercial thermometers are too slow and expensive. Discovered a tiny thermister which could measure electronic parts quickly. With a microprocessor and a display this thermister could be a highly sensitive thermometer. A large clock wouldn`t be affordable if it couldn`t perform some other function, however. Using the thermometer as the clock`s second function would make it affordable. The thermoclock would need to run on 6V battery power or AC power with automatic battery recharging. Looking at $40 for this thermoclock. Most of the cost is in the LEDs and microprocessor. Got 2 of the world`s most expensive LEDs for testing. Radioshack charges $2 for a single LED which is only $0. 10 in Hong Kong. After several tests including shaving off the lenses, the best position had both LED`s facing each other and the lenses left intact. The key was figuring out how to permanently mount LEDs in that position. Discovered fiberglass is resistant enough to heat to be used as a soldering surface. Lacking the money to make a fiberglass sheet for the entire clock, cut out 27 small fiberglass pieces to mount LEDs on.

Went through a few respirators grinding those out. So much dust is coating the apartment now that breathing is like falling in love with members. Unlike french fry grease or cigarette smoke, fiberglass dust doesn`t make you cough right away. You can breathe it for several minutes before dying. Discovered using PNP transistors as current sinks is far more efficient than using NPN transistors as current sources. The switching voltage needs not be limited to the voltage of the gadget being powered with a PNP transistor, so switching a 2.

2V LED with 5V is possible. Some other projects at Heroine Virtual reached a point where they required themometer testing to go any further so now our full attention is on HeroineClock. Finding enough money for the LEDs was a real problem. Though bright, the test LED`s were at the upper end of LED brightness. No-one in the US has LED`s that bright for less than $2. The dollar collapsed in 2004 and semiconductor devices, which all must be imported, have become super expensive.

Speaking of heroines, finally put together a heroine lightning bolt suitable for laminating rocket engines and power supplies and making clock icons out of. The largest LED manufacturing project in the US since 0 A. D. took place. An army of American welders went through a massive amount of wire and solder, erecting this monster of electronics.

Aren`t you glad you don`t need to build this. All the LEDs fire up for the first time. On top of the LEDs, we`ve layered wax paper, tinted foil, and acrylic plastic, which gives the clock a nice smooth face despite the uneaven wood. Without the tinted foil HeroineClock is blinding. Unfortunately these LEDs use an enourmous amount of power. The dream of running HeroineClock on batteries is all but impossible. Secondly it doesn`t look like the microcontroller has enough memory to do everything. Not sure how they intend the 68hc11 to be used since none of them have more than 512 bytes of flash. We obtained some free alternative microcontrollers before beginning HeroineClock. These were just in case the 68HC11 ran out of memory like it did. Even the 18 pin DIPs have 3x the memory of the 68HC11. The 44 pin PLCCs used in HeroineClock have 14k of flash, 28 times the memory of the 68HC11. There`s no way these`ll run out of memory. Unfortunately these microcontrollers have no serial port programming. Instead you must bit bang several pins fr 🔗 External reference