Home-Built Dye Laser

Dye lasers are a distinct category of lasers that utilize a liquid as their lasing medium. Depending on the specific dye employed, these lasers can produce output across a wide range of wavelengths, including the visible spectrum and beyond. Typically, commercial dye lasers are pumped by other lasers. For instance, Rhodamine-B, a commonly used dye for the red region, is frequently pumped by an argon ion laser operating at 514 nm for continuous-wave (CW) operation or by a doubled YAG laser at 532 nm when pulsed. A suitable flashlamp can also serve as a pump source; however, it must be a high-intensity flashlamp with a rapid rise time, which can be constructed at home. The overall assembly of a flashlamp-pumped dye laser is relatively simple compared to many other laser types discussed in this context. Generally, a minimal vacuum system is required for the home-built flashlamp, and there is no need for specialized glass work or exotic gases, although sourcing highly pure dyes may require effort. The associated hazards are moderate; some organic dye materials are toxic, and a high-voltage power supply—characterized by low current but high energy storage—must be employed to activate the flashlamp. The output from a home-built dye laser can produce coherent light pulses with sufficient energy to pose a vision hazard. Given the lack of concrete information regarding the actual power or energy achievable with such home-built designs, it is prudent to assume a higher power level until verified otherwise.

Electrical safety is paramount, as power supplies can be lethal. For instance, neon sign transformer-based power supplies can deliver sufficient voltage and current to be fatal. The energy storage capacitor charged for the flashlamp can also be extremely dangerous. Even if not fatal, an electric shock can cause involuntary reactions that may lead to accidents. Adhering to Safety Guidelines for High Voltage and/or Line Powered Equipment is essential. All connections should be insulated, and barriers must be installed to prevent contact with high voltage.

Chemically, many laser dyes are toxic, and their solvents can be both toxic and flammable. Appropriate precautions should be taken during use, and hazardous materials should be disposed of responsibly. Warning signs for both laser radiation and high voltage should be clearly displayed. It is advised to keep pets and small children away from the area and ensure that everyone present is informed about the potential dangers. The use of laser safety goggles specific to the wavelengths of the laser is highly recommended. Additional resources on laser safety can be found in relevant literature, including safety labels and signs specifically designed for laser applications.

For those interested in constructing a home-built dye laser, it is crucial to follow specific guidelines that will significantly impact the final output power, beam quality, and the production of coherent light. After achieving a functional laser, modifications can be made incrementally. The dye laser can be pumped using either an air flashlamp or a nitrogen laser, assuming one has already constructed the latter. Standard disposable camera flash units or large studio strobes are not suitable due to their insufficient performance.

The design of a home-built dye laser involves several key components. The laser cavity is typically formed by two mirrors, one of which is partially reflective, allowing a portion of the laser light to exit as the output beam. The dye solution is contained within the cavity, and the pump source, whether a flashlamp or another laser, is positioned to excite the dye molecules. The choice of dye and the configuration of the optical components will influence the efficiency and characteristics of the laser output. Proper alignment of the optical components is critical to achieving optimal performance. Additionally, a cooling system may be necessary to manage the heat generated during operation, ensuring stable performance and longevity of the components.

In summary, constructing a home-built dye laser requires careful consideration of safety, component selection, and design principles to ensure a successful and safe operation.Dye lasers are unique in that they are a class of lasers whose lasing medium is a liquid. Depending on the particular dye used, output can be at a wide range of wavelengths spanning the visible spectrum and beyond. Commercial dye lasers are often pumped by other lasers. For example, Rhodamine-B, a common dye used in dye lasers for the red region, is often pumped with an argon ion laser at 514 nm for CW operation or a doubled YAG laser at 532 nm when pulsed. A suitable flashlamp can also be used as a pump source (but not just any old electronic flash - it needs to be very intense with a fast rise-time).

As it turns out, this can easily be home-made. In fact, the overall construction of a flashlamp pumped dye laser is quite simple and straightforward, at least compared to nearly all of the other lasers discussed in this chapter. At most, a minimal vacuum system is required (for the home-made flashlamp) and there is absolutely no special glass work or need for exotic gases (though finding the highly pure dyes may require a little finger-work).

The hazards are also relatively moderate - some of the organic dye materials are toxic and a high voltage power supply (low current but a BIG energy storage capacitor) is needed to fire the flashlamp. Laser output: The home-built Dye laser may be capable of producing a pulses of coherent light with enough energy to be a hazard to vision.

Since there doesn`t seem to be any hard information on the actual power or energy obtainable with this or similar home-built laser designs, it is important to take precautions assuming a higher power until determined otherwise. Electrical: The power supplies can be lethal. Neon sign transformer based power supplies have enough voltage and current to stop a heart, The charged energy storage capacitor for the flashlamp can be truly deadly.

Even if you aren`t killed, the shock may startle you into doing something you might regret. Make sure you read and follow the Safety Guidelines for High Voltage and/or Line Powered Equipment. Insulate all connections and install barriers to prevent contact with the high voltage. Chemicals: Many laser dyes are toxic. Their solvents may be both toxic and flammable. Take appropriate precautions in use and dispose of these hazardous materials in a responsible way. Provide proper warning signs for both the laser radiation and high voltage. Keep pets and small children out of the area and make sure everyone present is instructed as to the dangers. The use of proper laser safety goggles for the specific wavelength(s) of your laser are highly recommended.

For more information, see the chapter: Laser Safety. Sample safety labels which can be edited for this laser can be found in the section: Laser Safety Labels and Signs. In addition to the article in: "Light and its Uses", there is also a fine article on the operation of organic dye lasers in the February 1969 issue of Scientific American.

(This also happens to be the same issue that features plans for the home-built argon ion laser. ). The following should also be of interest: Puls Laser (German) has virtually all of the home-built laser types including CO2, N2 (including TEA), ion, ruby, dye, and some that aren`t covered here. It includes descriptions, photos, references, and other information. An English translation would be most welcome as Altavista does less than a stellar job and doesn`t follow the frame links.

These set of guidelines should be followed during construction of your first home-built dye laser. The factors below will greatly influence the ultimate output power, beam quality, and whether it produces any coherent light at all! Once you have a working laser, feel free to make modifications - one at a time. Pump the dye laser with either the air flashlamp or your nitrogen laser (you have already built that, correct ).

Disposable camera flash units or even large studio strobes won`t work due to their exc 🔗 External reference

Electrical safety is paramount, as power supplies can be lethal. For instance, neon sign transformer-based power supplies can deliver sufficient voltage and current to be fatal. The energy storage capacitor charged for the flashlamp can also be extremely dangerous. Even if not fatal, an electric shock can cause involuntary reactions that may lead to accidents. Adhering to Safety Guidelines for High Voltage and/or Line Powered Equipment is essential. All connections should be insulated, and barriers must be installed to prevent contact with high voltage.

Chemically, many laser dyes are toxic, and their solvents can be both toxic and flammable. Appropriate precautions should be taken during use, and hazardous materials should be disposed of responsibly. Warning signs for both laser radiation and high voltage should be clearly displayed. It is advised to keep pets and small children away from the area and ensure that everyone present is informed about the potential dangers. The use of laser safety goggles specific to the wavelengths of the laser is highly recommended. Additional resources on laser safety can be found in relevant literature, including safety labels and signs specifically designed for laser applications.

For those interested in constructing a home-built dye laser, it is crucial to follow specific guidelines that will significantly impact the final output power, beam quality, and the production of coherent light. After achieving a functional laser, modifications can be made incrementally. The dye laser can be pumped using either an air flashlamp or a nitrogen laser, assuming one has already constructed the latter. Standard disposable camera flash units or large studio strobes are not suitable due to their insufficient performance.

The design of a home-built dye laser involves several key components. The laser cavity is typically formed by two mirrors, one of which is partially reflective, allowing a portion of the laser light to exit as the output beam. The dye solution is contained within the cavity, and the pump source, whether a flashlamp or another laser, is positioned to excite the dye molecules. The choice of dye and the configuration of the optical components will influence the efficiency and characteristics of the laser output. Proper alignment of the optical components is critical to achieving optimal performance. Additionally, a cooling system may be necessary to manage the heat generated during operation, ensuring stable performance and longevity of the components.

In summary, constructing a home-built dye laser requires careful consideration of safety, component selection, and design principles to ensure a successful and safe operation.Dye lasers are unique in that they are a class of lasers whose lasing medium is a liquid. Depending on the particular dye used, output can be at a wide range of wavelengths spanning the visible spectrum and beyond. Commercial dye lasers are often pumped by other lasers. For example, Rhodamine-B, a common dye used in dye lasers for the red region, is often pumped with an argon ion laser at 514 nm for CW operation or a doubled YAG laser at 532 nm when pulsed. A suitable flashlamp can also be used as a pump source (but not just any old electronic flash - it needs to be very intense with a fast rise-time).

As it turns out, this can easily be home-made. In fact, the overall construction of a flashlamp pumped dye laser is quite simple and straightforward, at least compared to nearly all of the other lasers discussed in this chapter. At most, a minimal vacuum system is required (for the home-made flashlamp) and there is absolutely no special glass work or need for exotic gases (though finding the highly pure dyes may require a little finger-work).

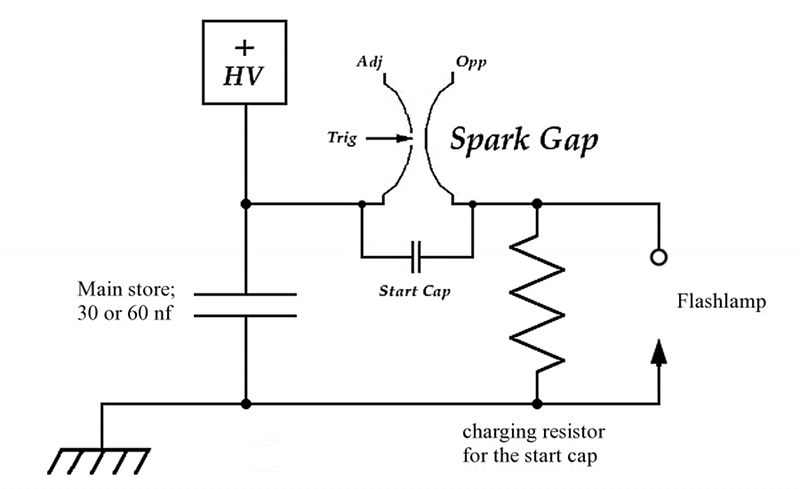

The hazards are also relatively moderate - some of the organic dye materials are toxic and a high voltage power supply (low current but a BIG energy storage capacitor) is needed to fire the flashlamp. Laser output: The home-built Dye laser may be capable of producing a pulses of coherent light with enough energy to be a hazard to vision.

Since there doesn`t seem to be any hard information on the actual power or energy obtainable with this or similar home-built laser designs, it is important to take precautions assuming a higher power until determined otherwise. Electrical: The power supplies can be lethal. Neon sign transformer based power supplies have enough voltage and current to stop a heart, The charged energy storage capacitor for the flashlamp can be truly deadly.

Even if you aren`t killed, the shock may startle you into doing something you might regret. Make sure you read and follow the Safety Guidelines for High Voltage and/or Line Powered Equipment. Insulate all connections and install barriers to prevent contact with the high voltage. Chemicals: Many laser dyes are toxic. Their solvents may be both toxic and flammable. Take appropriate precautions in use and dispose of these hazardous materials in a responsible way. Provide proper warning signs for both the laser radiation and high voltage. Keep pets and small children out of the area and make sure everyone present is instructed as to the dangers. The use of proper laser safety goggles for the specific wavelength(s) of your laser are highly recommended.

For more information, see the chapter: Laser Safety. Sample safety labels which can be edited for this laser can be found in the section: Laser Safety Labels and Signs. In addition to the article in: "Light and its Uses", there is also a fine article on the operation of organic dye lasers in the February 1969 issue of Scientific American.

(This also happens to be the same issue that features plans for the home-built argon ion laser. ). The following should also be of interest: Puls Laser (German) has virtually all of the home-built laser types including CO2, N2 (including TEA), ion, ruby, dye, and some that aren`t covered here. It includes descriptions, photos, references, and other information. An English translation would be most welcome as Altavista does less than a stellar job and doesn`t follow the frame links.

These set of guidelines should be followed during construction of your first home-built dye laser. The factors below will greatly influence the ultimate output power, beam quality, and whether it produces any coherent light at all! Once you have a working laser, feel free to make modifications - one at a time. Pump the dye laser with either the air flashlamp or your nitrogen laser (you have already built that, correct ).

Disposable camera flash units or even large studio strobes won`t work due to their exc 🔗 External reference