Wireless Stepper Motor Control using Laser and IC555

Wireless stepper motor speed control project using a laser and IC555. This project provides insights into the fundamentals and circuit construction for controlling the speed of a wireless stepper motor utilizing a laser and the IC 555 timer.

The project centers around a wireless stepper motor control system that employs a laser as a triggering mechanism and the IC 555 timer integrated circuit for speed regulation. The primary objective is to create a user-friendly interface that allows for precise control of the stepper motor's speed remotely.

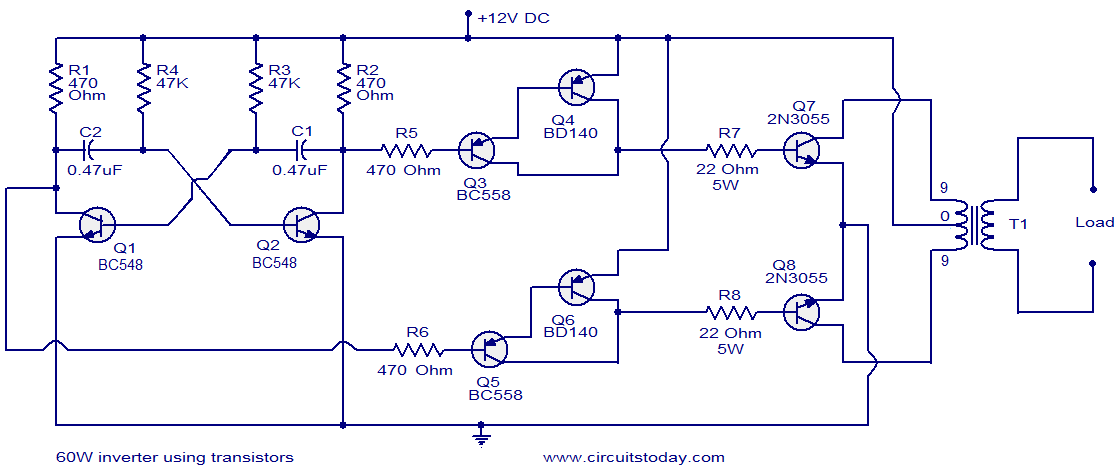

The circuit design begins with the IC 555 configured in astable mode, generating a pulse-width modulation (PWM) signal. This PWM signal is crucial for controlling the speed of the stepper motor. The duty cycle of the PWM signal can be adjusted by varying the resistance and capacitance values in the circuit, which in turn alters the average voltage supplied to the motor.

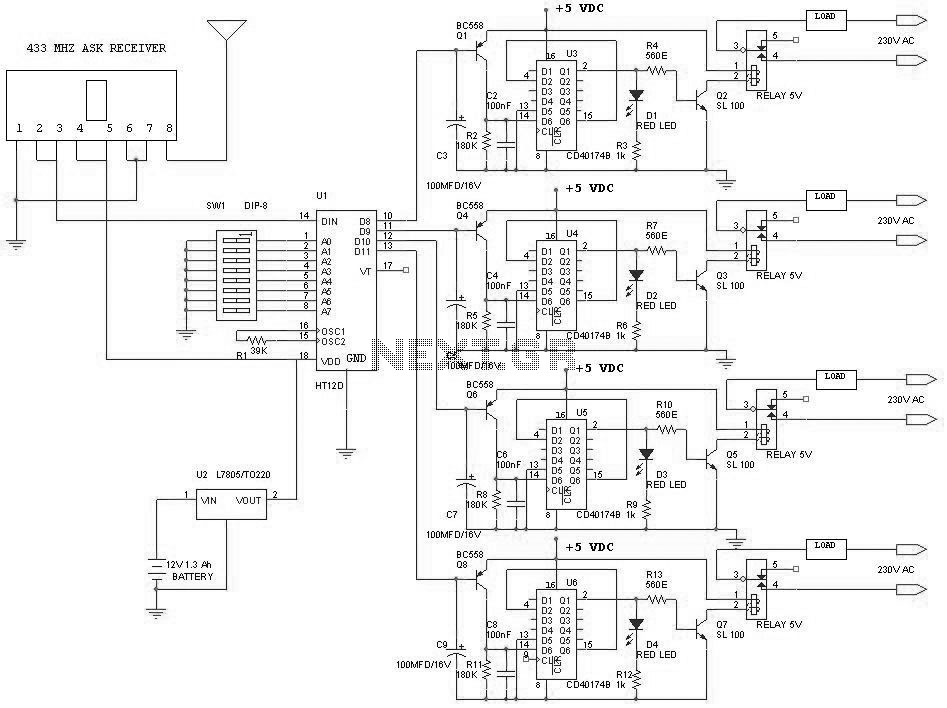

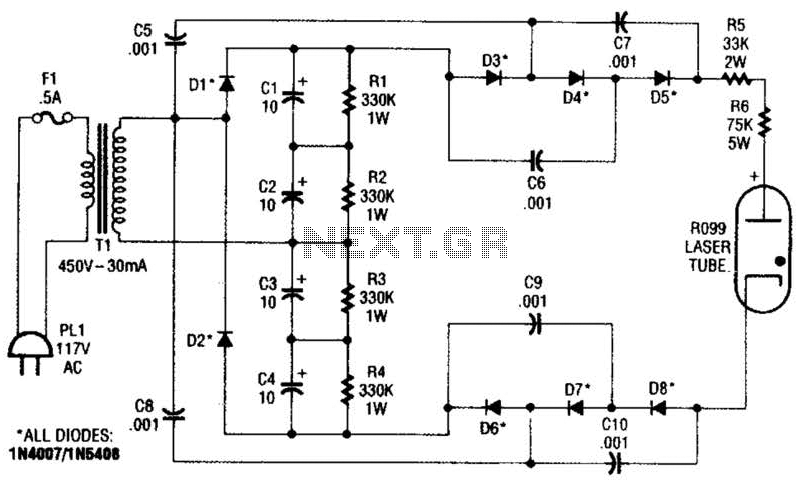

Incorporating a laser into this design serves as a non-contact method for initiating the motor's operation. A photodiode or phototransistor is used to detect the laser beam. When the laser beam is interrupted or received, it triggers the IC 555 timer to produce the PWM signal necessary for the motor's operation.

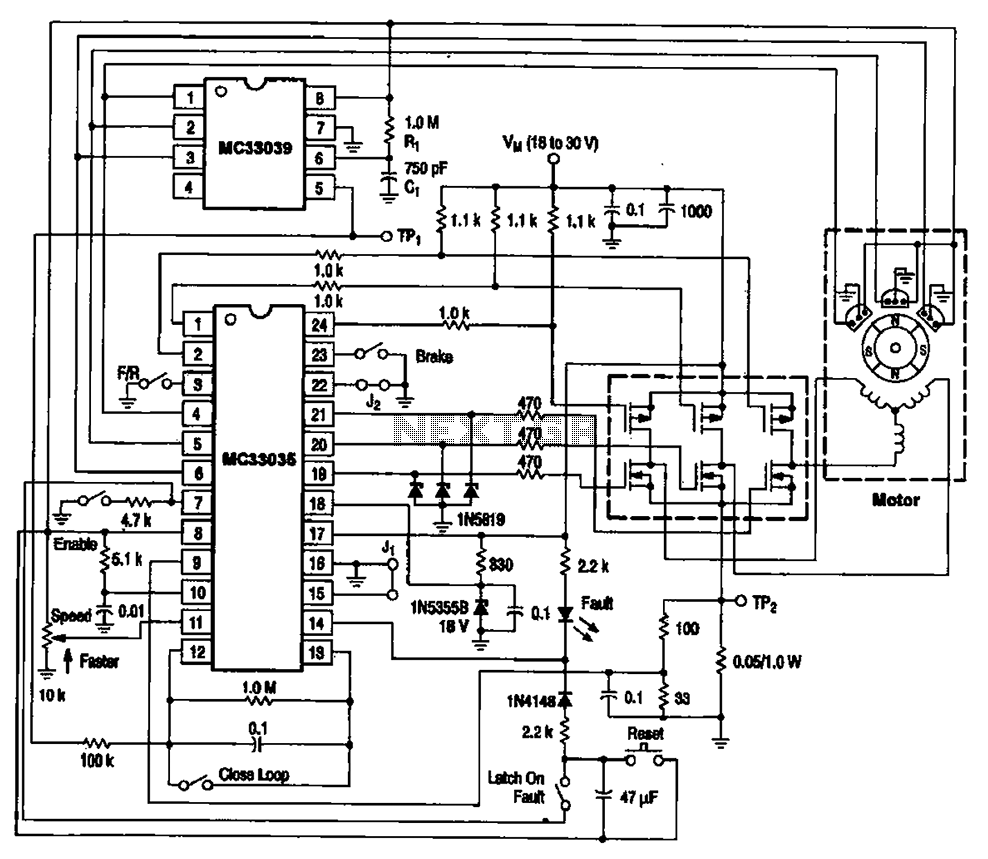

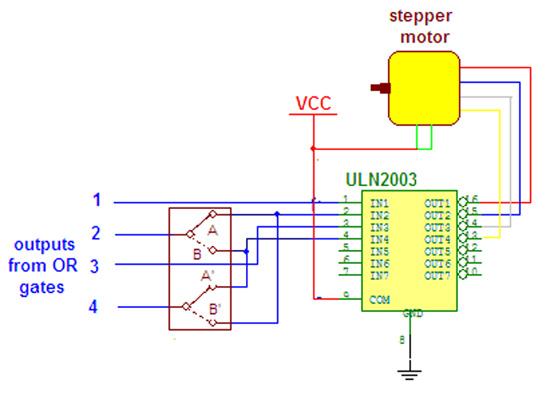

The stepper motor itself is connected to a driver circuit, which interprets the PWM signal from the IC 555 and translates it into step commands for the motor. This driver circuit is essential for ensuring that the motor receives the correct voltage and current levels to operate efficiently and effectively.

Overall, this wireless stepper motor speed control project showcases the integration of optical sensors with timer circuits, providing an innovative approach to motor control applications. The versatility of the IC 555 timer, combined with the non-contact triggering method of the laser, allows for a wide range of potential applications in robotics, automation, and remote control systems.Wireless stepper motor speed control project using laser and IC555. Read to know about basics and circuit construction using a wireless stepper motor which has speed control through laser and IC 555 🔗 External reference

The project centers around a wireless stepper motor control system that employs a laser as a triggering mechanism and the IC 555 timer integrated circuit for speed regulation. The primary objective is to create a user-friendly interface that allows for precise control of the stepper motor's speed remotely.

The circuit design begins with the IC 555 configured in astable mode, generating a pulse-width modulation (PWM) signal. This PWM signal is crucial for controlling the speed of the stepper motor. The duty cycle of the PWM signal can be adjusted by varying the resistance and capacitance values in the circuit, which in turn alters the average voltage supplied to the motor.

Incorporating a laser into this design serves as a non-contact method for initiating the motor's operation. A photodiode or phototransistor is used to detect the laser beam. When the laser beam is interrupted or received, it triggers the IC 555 timer to produce the PWM signal necessary for the motor's operation.

The stepper motor itself is connected to a driver circuit, which interprets the PWM signal from the IC 555 and translates it into step commands for the motor. This driver circuit is essential for ensuring that the motor receives the correct voltage and current levels to operate efficiently and effectively.

Overall, this wireless stepper motor speed control project showcases the integration of optical sensors with timer circuits, providing an innovative approach to motor control applications. The versatility of the IC 555 timer, combined with the non-contact triggering method of the laser, allows for a wide range of potential applications in robotics, automation, and remote control systems.Wireless stepper motor speed control project using laser and IC555. Read to know about basics and circuit construction using a wireless stepper motor which has speed control through laser and IC 555 🔗 External reference