How to Build Toxic Gas Detector and Alarm Circuit with TGS813

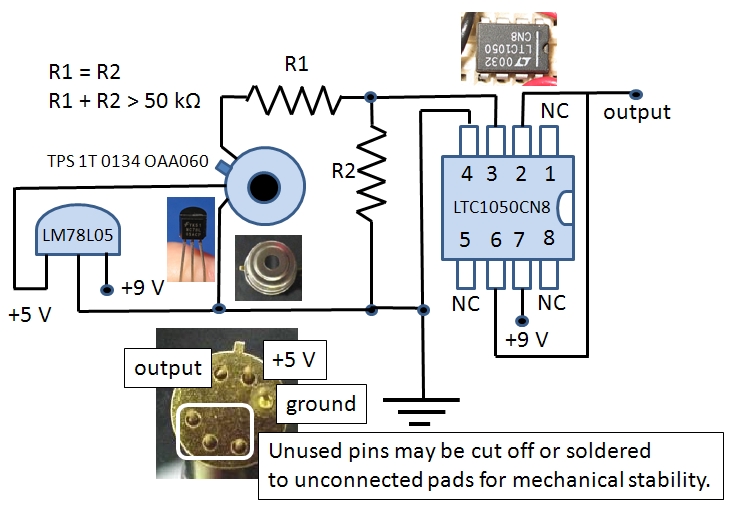

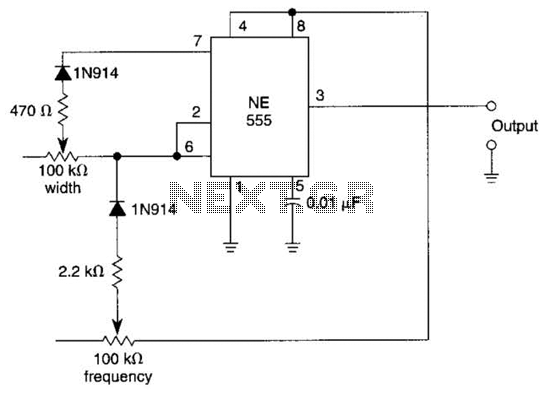

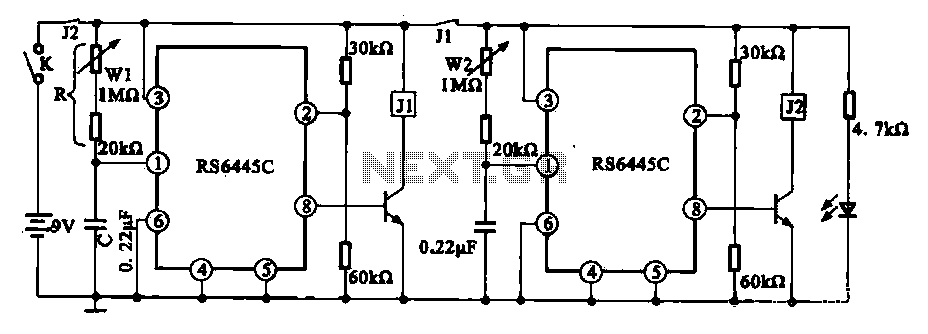

The danger always exists when fuel gases such as propane or natural gas are confined to a small area. The toxic gas alarm utilizes a tin-oxide semiconductor. A coil of thin wire is heated by a 12 V battery through integrated circuits IC1 and IC2, which pulse the voltage to the sensor coil, significantly saving energy. Diode Zener D1 provides a constant voltage to the filament coil sensor. The resistance of the sensor decreases when exposed to toxic gases such as hydrogen, carbon monoxide, and propane. To reduce the sensor's resistance, the gate voltage of the silicon-controlled rectifier (SCR) increases. When the gate threshold voltage is reached, the SCR activates, triggering a buzzer alarm. Once activated, the buzzer and switch S1 must be used to reset the alarm. Due to the sensor's thermal inertia, S1 must remain off for about three to four minutes after the initial activation to allow the sensor to stabilize and avoid false alarms. The sensitivity control R7 should be set to the desired value before activating the SCR. The toxic gas alarm is sensitive to levels below 100 ppm of carbon monoxide, making it useful for applications in gas boats, sheds, and cabins. This device could potentially save lives. Several companies listed in the appendix provide plans and kits for various toxic gas sensors.

The described toxic gas alarm circuit is designed to detect the presence of harmful gases in confined spaces, utilizing a tin-oxide semiconductor sensor that changes resistance in the presence of specific gases. The 12 V battery powers the circuit, which includes two integrated circuits (IC1 and IC2) that control the pulsing voltage supplied to a heated coil. This heating element is essential for the operation of the sensor, as it enhances the sensitivity of the tin-oxide material.

The Zener diode D1 plays a critical role in maintaining a stable voltage across the filament coil, ensuring consistent heating and reliable sensor performance. The operation of the sensor is based on the principle that exposure to toxic gases like hydrogen, carbon monoxide, and propane reduces the resistance of the tin-oxide material. As the concentration of these gases increases, the resistance drops, which in turn raises the gate voltage of the SCR.

When this gate voltage reaches a predetermined threshold, the SCR activates, allowing current to flow through the buzzer, which emits an alarm sound to alert users of dangerous gas levels. To prevent false alarms due to thermal inertia, the switch S1 must remain open for a few minutes after the alarm is triggered, giving the sensor time to stabilize.

The sensitivity of the alarm can be adjusted using the resistor R7, allowing users to calibrate the device according to their specific needs. With the capability to detect carbon monoxide levels below 100 ppm, this alarm is particularly suited for environments such as gas boats, sheds, and cabins where gas leaks could pose serious safety risks. The availability of plans and kits from various manufacturers enhances accessibility for individuals and organizations looking to implement toxic gas detection solutions.The danger always exists, when the fuel gases such as propane or gas are confined to a small area. The alarm of toxic gases figs. 1-45 utilizes a tin-oxide-semiconductor. A coil of thin wire heated by a battery 12 V via IC1 and IC2, which pulses the voltage to the coil of the sensor, saving a significant amount of energy. Diode Zener Dl provides a constant voltage to the filament coil sensor. resistance of the sensor reduces the sensor is exposed to toxic gases such as hydrogen, carbon Carbon monoxide and propane. To reduce the resistance of the sensor, the SCR gate voltage increases. When the gate threshold voltage is reached, the SCR fires and a buzzer alarm is activated. Once activated, the bell and the switch S1 should be used to reset the alarm. Since the sensor has a good deal of thermal inertia, S1 must be off or open for about three or four minutes after the initial activation, allowing the sensor to stabilize, thus avoiding false alarms.

R7 sensitivity control set to the desired value, before the activation of SCR. The toxic gas alarm is sensitive to less than 100 ppm of carbon monoxide. This alarm is useful for simple gas boats, sheds and cabins. You could save a life. Some of the companies listed in the Appendix to offer plans and kits for various toxic gas sensors. 🔗 External reference

The described toxic gas alarm circuit is designed to detect the presence of harmful gases in confined spaces, utilizing a tin-oxide semiconductor sensor that changes resistance in the presence of specific gases. The 12 V battery powers the circuit, which includes two integrated circuits (IC1 and IC2) that control the pulsing voltage supplied to a heated coil. This heating element is essential for the operation of the sensor, as it enhances the sensitivity of the tin-oxide material.

The Zener diode D1 plays a critical role in maintaining a stable voltage across the filament coil, ensuring consistent heating and reliable sensor performance. The operation of the sensor is based on the principle that exposure to toxic gases like hydrogen, carbon monoxide, and propane reduces the resistance of the tin-oxide material. As the concentration of these gases increases, the resistance drops, which in turn raises the gate voltage of the SCR.

When this gate voltage reaches a predetermined threshold, the SCR activates, allowing current to flow through the buzzer, which emits an alarm sound to alert users of dangerous gas levels. To prevent false alarms due to thermal inertia, the switch S1 must remain open for a few minutes after the alarm is triggered, giving the sensor time to stabilize.

The sensitivity of the alarm can be adjusted using the resistor R7, allowing users to calibrate the device according to their specific needs. With the capability to detect carbon monoxide levels below 100 ppm, this alarm is particularly suited for environments such as gas boats, sheds, and cabins where gas leaks could pose serious safety risks. The availability of plans and kits from various manufacturers enhances accessibility for individuals and organizations looking to implement toxic gas detection solutions.The danger always exists, when the fuel gases such as propane or gas are confined to a small area. The alarm of toxic gases figs. 1-45 utilizes a tin-oxide-semiconductor. A coil of thin wire heated by a battery 12 V via IC1 and IC2, which pulses the voltage to the coil of the sensor, saving a significant amount of energy. Diode Zener Dl provides a constant voltage to the filament coil sensor. resistance of the sensor reduces the sensor is exposed to toxic gases such as hydrogen, carbon Carbon monoxide and propane. To reduce the resistance of the sensor, the SCR gate voltage increases. When the gate threshold voltage is reached, the SCR fires and a buzzer alarm is activated. Once activated, the bell and the switch S1 should be used to reset the alarm. Since the sensor has a good deal of thermal inertia, S1 must be off or open for about three or four minutes after the initial activation, allowing the sensor to stabilize, thus avoiding false alarms.

R7 sensitivity control set to the desired value, before the activation of SCR. The toxic gas alarm is sensitive to less than 100 ppm of carbon monoxide. This alarm is useful for simple gas boats, sheds and cabins. You could save a life. Some of the companies listed in the Appendix to offer plans and kits for various toxic gas sensors. 🔗 External reference