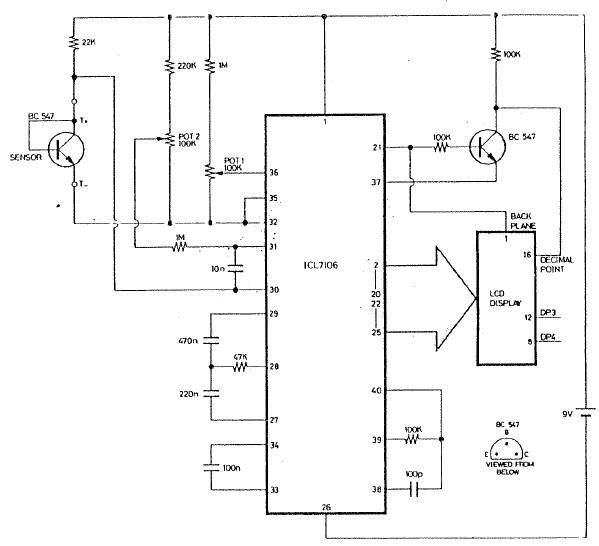

ICL7106 electronic thermometer circuit design project

The ICL7106 integrated circuit contains all the active circuitry for a 3 1/2 digit panel meter (DPM) in a single chip. It was designed to interface directly with a liquid crystal display (LCD). The potential difference across a silicon diode is dependent on its temperature and the current flowing through it. The temperature coefficient is negative, meaning that the voltage decreases with increasing temperature. This decrease is approximately linear and typically measures -2.2 mV/°C. The temperature meter measures the potential difference across the diode after an offset voltage, which is accessible from pins 1 and 32 of the 7106, has been applied. Two 100K 10-turn trimpots are utilized to calibrate the sensor at two known temperatures. Calibration can be easily performed using a mixture of ice and water to establish a reference point of zero degrees Celsius, and by placing the sensor in a jet of steam from a boiling kettle to calibrate for 100 degrees Celsius.

The ICL7106 is a versatile integrated circuit that serves as the core of a digital panel meter, integrating all necessary components for measurement and display in a compact form factor. It is specifically designed to work seamlessly with LCDs, making it suitable for various applications where visual output of measured values is required. The device operates based on the principle that the voltage across a silicon diode varies with temperature and current, exhibiting a negative temperature coefficient. This characteristic allows the ICL7106 to function effectively as a temperature measurement device.

To utilize the ICL7106 for temperature measurement, the user must add an offset voltage, which can be derived from designated pins on the IC. The calibration process is straightforward, relying on two adjustable 100K ohm trimpots that facilitate fine-tuning of the device for accurate readings at known temperature points. The calibration procedure involves immersing the diode in a mixture of ice and water to achieve a precise zero-degree Celsius reference and exposing the sensor to steam from boiling water to establish a 100-degree Celsius reference. This method ensures that the temperature readings are accurate and reliable across the operational range of the device.

In summary, the ICL7106 integrated circuit is a complete solution for digital temperature measurement, providing a user-friendly interface for calibration and a direct connection to LCD displays, making it an ideal choice for various electronic applications requiring accurate temperature sensing.The ICL7106 Integrated circuit contain all the active circuitry for a 3 1/2 digit panel meter (DPM) in a single chip. It was designed to interface directly to a liquid crystal display (LCD). The potential difference across a silicon diode is dependent on its temperature and current through it.

Its temperature coefficient is negative, that is, the voltage falls with increasing temperature. This fall is approximately linear and is typically -2. 2mV/oC. The temperature meter measures the potential difference across the diode after an offset voltage which is available from pins 1 and 32 of the 7106 has been added. The two 100K 10-turn trimpots are used to calibrate the sensor at two known temperatures. The calibration is easily done using water with ice in it to calibrate zero degrees Centigrade and putting the sensor in a jet of steam from a boiling water kettle to calibrate for 100 C degrees.

🔗 External reference

The ICL7106 is a versatile integrated circuit that serves as the core of a digital panel meter, integrating all necessary components for measurement and display in a compact form factor. It is specifically designed to work seamlessly with LCDs, making it suitable for various applications where visual output of measured values is required. The device operates based on the principle that the voltage across a silicon diode varies with temperature and current, exhibiting a negative temperature coefficient. This characteristic allows the ICL7106 to function effectively as a temperature measurement device.

To utilize the ICL7106 for temperature measurement, the user must add an offset voltage, which can be derived from designated pins on the IC. The calibration process is straightforward, relying on two adjustable 100K ohm trimpots that facilitate fine-tuning of the device for accurate readings at known temperature points. The calibration procedure involves immersing the diode in a mixture of ice and water to achieve a precise zero-degree Celsius reference and exposing the sensor to steam from boiling water to establish a 100-degree Celsius reference. This method ensures that the temperature readings are accurate and reliable across the operational range of the device.

In summary, the ICL7106 integrated circuit is a complete solution for digital temperature measurement, providing a user-friendly interface for calibration and a direct connection to LCD displays, making it an ideal choice for various electronic applications requiring accurate temperature sensing.The ICL7106 Integrated circuit contain all the active circuitry for a 3 1/2 digit panel meter (DPM) in a single chip. It was designed to interface directly to a liquid crystal display (LCD). The potential difference across a silicon diode is dependent on its temperature and current through it.

Its temperature coefficient is negative, that is, the voltage falls with increasing temperature. This fall is approximately linear and is typically -2. 2mV/oC. The temperature meter measures the potential difference across the diode after an offset voltage which is available from pins 1 and 32 of the 7106 has been added. The two 100K 10-turn trimpots are used to calibrate the sensor at two known temperatures. The calibration is easily done using water with ice in it to calibrate zero degrees Centigrade and putting the sensor in a jet of steam from a boiling water kettle to calibrate for 100 C degrees.

🔗 External reference