Intelligent NiCd/NiMH Battery Charger

This affordable and simple-to-construct NiCd/NiMH battery charger is designed for the automatic charging of various batteries used in numerous applications. Reliable chargers are typically costly, while inexpensive chargers that come with original equipment often fail to charge cells correctly, significantly reducing their lifespan. This intelligent charger was engineered for high current applications.

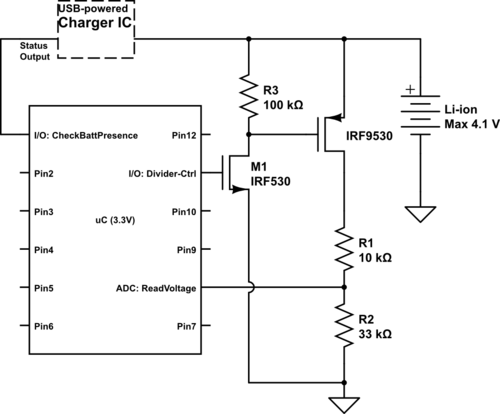

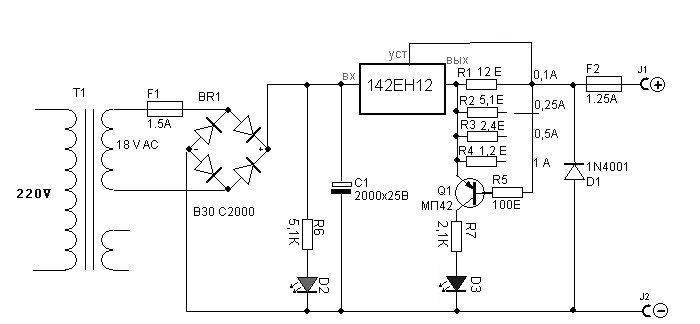

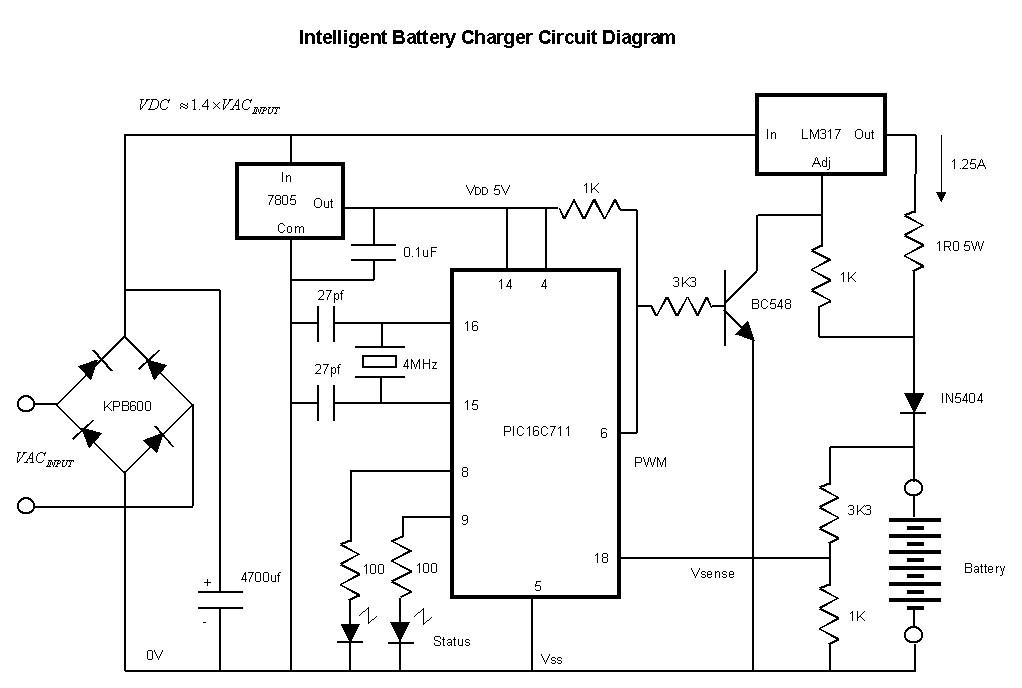

The NiCd/NiMH battery charger circuit typically consists of several key components, including a transformer, rectifier, voltage regulator, and a microcontroller or comparator for monitoring battery voltage and temperature. The transformer converts the mains voltage to a lower AC voltage suitable for charging. The rectifier, often a bridge rectifier configuration, converts the AC voltage to a pulsating DC voltage, which is then smoothed by a filter capacitor to provide a steady DC output.

The charging process is controlled by a microcontroller or a dedicated integrated circuit that monitors the voltage across the battery terminals. This component is crucial for implementing a smart charging algorithm, which may include constant current (CC) and constant voltage (CV) phases. During the CC phase, the charger supplies a fixed current until the battery reaches a predefined voltage threshold. The circuit then transitions to the CV phase, where the voltage is held constant while the current gradually decreases as the battery approaches full charge.

In addition to voltage monitoring, temperature sensing may be incorporated to prevent overheating, which can lead to battery damage or failure. Thermistors or temperature sensors can be placed in proximity to the battery pack, and the microcontroller can adjust the charging current or halt the charging process if excessive temperatures are detected.

Furthermore, the design may include indicators such as LEDs to provide visual feedback on the charging status. A green LED may indicate that the battery is fully charged, while a red LED could indicate that charging is in progress.

Safety features are also paramount in the design of this charger. Over-voltage protection, short-circuit protection, and reverse polarity protection can be implemented using additional circuit elements such as fuses, diodes, and protection ICs.

Overall, this NiCd/NiMH battery charger circuit represents an efficient and cost-effective solution for charging a variety of battery types, enhancing their longevity and performance through intelligent charging techniques.This cheap and easy to build NiCd/NiMH Battery Charger is suitable for automatically charging a wide range of batteries for many applications. Proper chargers are usually expensive and cheap chargers supplied with the original equipment often incorrectly charge the cells and dramatically shorten their life.

This ˜intelligent charger was designed for high cu.. 🔗 External reference

The NiCd/NiMH battery charger circuit typically consists of several key components, including a transformer, rectifier, voltage regulator, and a microcontroller or comparator for monitoring battery voltage and temperature. The transformer converts the mains voltage to a lower AC voltage suitable for charging. The rectifier, often a bridge rectifier configuration, converts the AC voltage to a pulsating DC voltage, which is then smoothed by a filter capacitor to provide a steady DC output.

The charging process is controlled by a microcontroller or a dedicated integrated circuit that monitors the voltage across the battery terminals. This component is crucial for implementing a smart charging algorithm, which may include constant current (CC) and constant voltage (CV) phases. During the CC phase, the charger supplies a fixed current until the battery reaches a predefined voltage threshold. The circuit then transitions to the CV phase, where the voltage is held constant while the current gradually decreases as the battery approaches full charge.

In addition to voltage monitoring, temperature sensing may be incorporated to prevent overheating, which can lead to battery damage or failure. Thermistors or temperature sensors can be placed in proximity to the battery pack, and the microcontroller can adjust the charging current or halt the charging process if excessive temperatures are detected.

Furthermore, the design may include indicators such as LEDs to provide visual feedback on the charging status. A green LED may indicate that the battery is fully charged, while a red LED could indicate that charging is in progress.

Safety features are also paramount in the design of this charger. Over-voltage protection, short-circuit protection, and reverse polarity protection can be implemented using additional circuit elements such as fuses, diodes, and protection ICs.

Overall, this NiCd/NiMH battery charger circuit represents an efficient and cost-effective solution for charging a variety of battery types, enhancing their longevity and performance through intelligent charging techniques.This cheap and easy to build NiCd/NiMH Battery Charger is suitable for automatically charging a wide range of batteries for many applications. Proper chargers are usually expensive and cheap chargers supplied with the original equipment often incorrectly charge the cells and dramatically shorten their life.

This ˜intelligent charger was designed for high cu.. 🔗 External reference