laser sup circuit

Working with lasers can be enjoyable and intriguing, but it can also be costly. High voltage power supplies for laser tubes are often more expensive than the tubes themselves. However, this power supply can be constructed using common components that are likely available in a typical electronics junk box. The key component is the transformer, which is a standard 9V 1A unit that is connected in reverse for step-up voltage. It is important to note that some users may encounter difficulties with this power supply due to minor variations in transformers. For additional information on laser power supplies, refer to Sam Goldwasser's Laser Supply Info Page. Resistor R2 is used to protect the laser tube from excessive current and should be soldered directly to the anode terminal of the tube. To determine the appropriate value for R2, start with a 500K 10W resistor and gradually decrease the resistance until the tube lights up and remains stable. The functionality of this circuit may vary depending on the transformer used, and its operation cannot be guaranteed. Proceed with caution, as some transformers may have very few secondary windings, which could lead to core saturation and essentially behave like a direct short. A transformer with more secondary windings (or primary in this configuration) will yield better results.

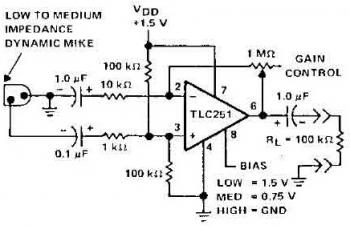

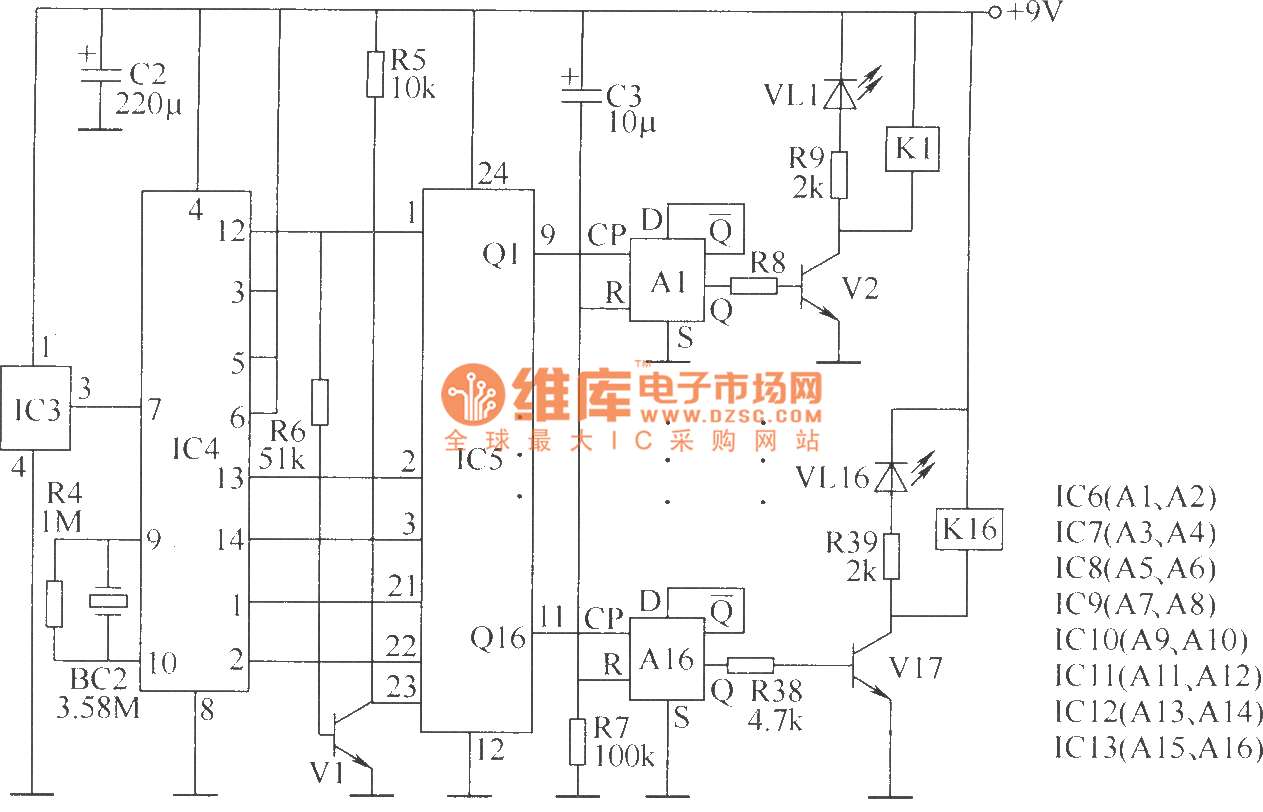

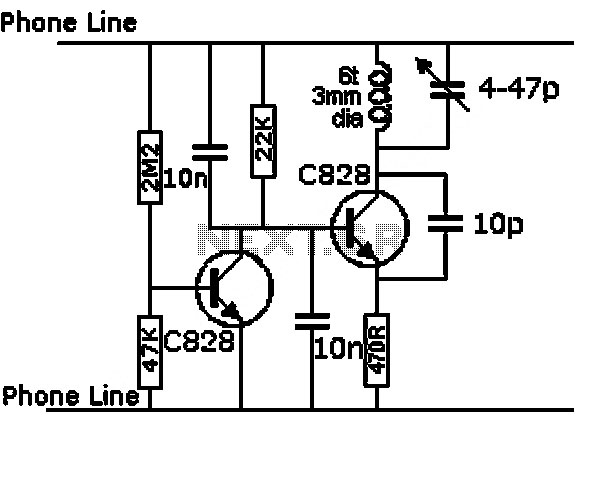

The circuit design for a high voltage power supply for laser tubes typically involves a few key components: a transformer, a rectifier, a filter capacitor, and a current-limiting resistor. The transformer, a 9V 1A unit, is connected in reverse to step up the voltage to the required levels for the laser tube operation. The output from the transformer is AC, which must be converted to DC using a rectifier, commonly a diode bridge configuration, to ensure a steady supply of current.

The filter capacitor serves to smooth out the rectified voltage, reducing ripple and providing a more stable DC output. The value of this capacitor can vary depending on the specific requirements of the laser tube and the desired performance characteristics.

Resistor R2 plays a critical role in protecting the laser tube from excessive current. It should be soldered directly to the anode terminal of the laser tube, and its value must be carefully selected. Starting with a 500K 10W resistor is advisable, and the resistance should be adjusted downward until the laser tube lights up consistently without flickering, indicating a stable operation.

It is essential to consider the specifications of the transformer being used, as variations in the number of secondary windings can significantly affect the circuit's performance. Transformers with fewer windings may saturate quickly, leading to a loss of efficiency and potentially damaging the circuit. Therefore, selecting a transformer with a higher number of secondary windings is recommended to achieve optimal performance.

This circuit should be assembled with caution and thorough testing, as the high voltage involved can pose safety risks. It is advisable to take necessary precautions, such as using insulated tools and wearing appropriate safety gear when working with high voltage electronics.If you have ever worked with lasers, you know how fun and interesting it can be, you also know how expensive it can be. The high voltage power supplies for the laser tubes are often more expensive then the tubes themselves.

This supply can be built with commmon parts, most of which you probably already have in your junk box. The secret is the tran sformer used. It is a common 9V 1A unit, connected backwards for step up. Please note that some people may have trouble with this supply. This is due to the slight difference in transformers. For more information on LASER power supplies, take a look at Sam Goldwasser`s Laser Supply Info Page. R2 Protects the laser tube from excess current. It should be soldered directly to the anode terminal on the tube. To find R2, start with a 500K 10W resistor and work down until the tube lights and remains stable. Depending on the transformer you use, the circuit may or may not work. I cannot guarantee the operation of this circuit. Build at your own risk. Some transformers contain very few secondary windings which will quickly saturate the core and basically act like a direct short.

The more secondary windings (that is, primary in this circuit) the better. 🔗 External reference

The circuit design for a high voltage power supply for laser tubes typically involves a few key components: a transformer, a rectifier, a filter capacitor, and a current-limiting resistor. The transformer, a 9V 1A unit, is connected in reverse to step up the voltage to the required levels for the laser tube operation. The output from the transformer is AC, which must be converted to DC using a rectifier, commonly a diode bridge configuration, to ensure a steady supply of current.

The filter capacitor serves to smooth out the rectified voltage, reducing ripple and providing a more stable DC output. The value of this capacitor can vary depending on the specific requirements of the laser tube and the desired performance characteristics.

Resistor R2 plays a critical role in protecting the laser tube from excessive current. It should be soldered directly to the anode terminal of the laser tube, and its value must be carefully selected. Starting with a 500K 10W resistor is advisable, and the resistance should be adjusted downward until the laser tube lights up consistently without flickering, indicating a stable operation.

It is essential to consider the specifications of the transformer being used, as variations in the number of secondary windings can significantly affect the circuit's performance. Transformers with fewer windings may saturate quickly, leading to a loss of efficiency and potentially damaging the circuit. Therefore, selecting a transformer with a higher number of secondary windings is recommended to achieve optimal performance.

This circuit should be assembled with caution and thorough testing, as the high voltage involved can pose safety risks. It is advisable to take necessary precautions, such as using insulated tools and wearing appropriate safety gear when working with high voltage electronics.If you have ever worked with lasers, you know how fun and interesting it can be, you also know how expensive it can be. The high voltage power supplies for the laser tubes are often more expensive then the tubes themselves.

This supply can be built with commmon parts, most of which you probably already have in your junk box. The secret is the tran sformer used. It is a common 9V 1A unit, connected backwards for step up. Please note that some people may have trouble with this supply. This is due to the slight difference in transformers. For more information on LASER power supplies, take a look at Sam Goldwasser`s Laser Supply Info Page. R2 Protects the laser tube from excess current. It should be soldered directly to the anode terminal on the tube. To find R2, start with a 500K 10W resistor and work down until the tube lights and remains stable. Depending on the transformer you use, the circuit may or may not work. I cannot guarantee the operation of this circuit. Build at your own risk. Some transformers contain very few secondary windings which will quickly saturate the core and basically act like a direct short.

The more secondary windings (that is, primary in this circuit) the better. 🔗 External reference