LED TesterCircuit

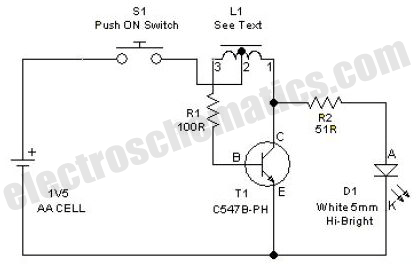

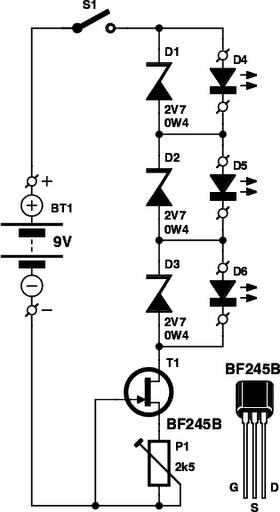

These small electronic lamps are quite practical and have a long lifespan. Approximately 40 years after Nick Holonyak invented the first LED, they have become nearly essential. Any dedicated electronics enthusiast typically keeps a few in their collection. Prior to utilizing LEDs, it is advisable to test them. An LED tester allows for testing even in low-light conditions. LEDs are now available in various shapes and colors, including types with clear, colorless packages and others with colored plastic casings. Many modern LEDs require less current than their older counterparts, and some can emit a significant amount of light when supplied with sufficient current. When working with used LEDs, it may be difficult to identify the leads. If the leads are intact, the shorter lead is the cathode, and the longer lead is the anode. In applications where multiple LEDs are used in a display, uniform brightness is desired, but this is not always achievable, even among LEDs of the same type. To minimize unnecessary soldering, it is prudent to test the LEDs beforehand. The circuit described can test up to three LEDs connected in series, with the capability to increase this number by using a higher supply voltage, allowing for 2.7 V for each additional LED. Zener diodes included in the circuit enable testing of one or two LEDs, and they ensure that if one or more LEDs are defective or connected in reverse polarity, the others will still function normally. Adding more LEDs requires an additional Zener diode for each position. The test current flowing through the LEDs is kept relatively constant by FET T1, which acts as a constant-current source, simplifying the circuit design. However, the tolerance range of FET characteristics can be quite broad. The FET used here comes in three variants: A, B, and C. The B version is employed, allowing the current through the LEDs to be adjusted via potentiometer P1 within a range of 1 to 7 mA. For higher current needs, a BF254C can be used, necessitating a higher supply voltage, such as connecting two 9-V batteries in series or using a mains adapter. It is important to note that some LEDs have a maximum rated current of only 5 mA; therefore, testing should begin at the lowest current setting by adjusting P1 to maximum resistance. The brightness observed will indicate if more current is needed. If an LED does not illuminate, it may be defective or incorrectly connected. It is advisable to reduce the current to the minimum level before reversing or replacing any LEDs. Labeling the polarity on the LED tester facilitates easy identification of the cathode and anode leads of the tested LEDs. An IC socket can be utilized as a test socket for convenient swapping of LEDs. The selected Zener diodes are suitable for testing red, yellow, and green LEDs, with red LEDs having a forward voltage of 1.6 V to 1.8 V, yellow LEDs at approximately 1.9 V, and green LEDs reaching up to 2 V. For testing modern blue or white LEDs, it is necessary to replace the Zener diodes with those rated at 4.7 V or 5.1 V, which also requires an increase in supply voltage, such as connecting two 9-V batteries in series.

The LED tester circuit is designed with simplicity and functionality in mind, allowing for the testing of multiple LEDs simultaneously while ensuring reliable operation even when faced with defective components. The use of a constant-current source through FET T1 is pivotal in maintaining consistent brightness across the tested LEDs, which is crucial for applications requiring uniformity in lighting. The inclusion of Zener diodes not only protects the circuit from potential damage due to incorrect LED polarity but also enhances the testing capability, making it versatile for various LED types. The adjustment feature provided by potentiometer P1 allows for fine-tuning of the current, accommodating different LED specifications and ensuring optimal performance.

Furthermore, the circuit's adaptability to different LED types, including the requirement for higher forward voltages for modern LEDs, underscores its practicality for hobbyists and professionals alike. The ability to use standard components such as IC sockets facilitates ease of use and maintenance, making this LED tester an invaluable tool in electronic projects involving LED displays or indicators. Overall, this LED tester circuit exemplifies an effective solution for ensuring the reliability and functionality of LEDs in various applications.You have to admit that these tiny electronic lamps are handy, and they last almost forever. Around 40 years after Nick Holanyak developed the first LED, they have become just about indispensable. Any self-respecting electronics hobbyist always has a few in his junk box. But before you use LEDs, it`s a good idea to check them out. With a LED tester , you can even do it in the dark! LEDs are available nowadays in all shapes and colors. There are types with clear, colorless packages, while others have colored plastic packages. Many modern types of LEDs need less current than older types. Some of them provide quite a puddle of light if you give them a decent amount of current. When you`re working with used LEDs from the junk box, there`s a good chance that you can`t tell which lead is which any more. (If the leads haven`t been trimmed, the short lead is always the cathode lead and the long lead is the anode lead.

) If you use several LEDs in a display where they all have the same current you naturally want all the LEDs to have the same brightness. But that`s not always the case, even with LEDs of the same type. To save yourself unnecessary soldering work, it`s a good idea to check the LEDs out first. That`s the job of the LED tester described here. This circuit can be used to test up to three LEDs at once, connected in series. You can easily increase that number by using a higher supply voltage. If you do so, you should allow 2. 7 V for each additional LED. The Zener diodes are included in the circuit so it can also be used to test one or two LEDs. Another benefit of the Zeners is that even if one or more of the LEDs are defective or connected with reverse polarity, the remaining ones will light up normally.

That makes it easy to spot suspect LEDs. If you extend the tester to handle more LEDs, you must add another Zener diode for each LED position. The test current that ows through the LEDs is held reasonably constant by FET T1, independent of the number of LEDs being tested.

The FET is used as a constant-current source to keep the circuit as simple as possible. The drawback of this approach is that the tolerance range of FET characteristics is especially large. The type used here even has three versions: A, B and C. We used the B version here so the current through the LEDs can be adjusted using potentiometer P1 over the range of 1 7 mA.

If you need more current, you can use a BF254C instead, but then you will also need a higher supply voltage. For example, you can connect two 9-V batteries in series or power the circuit from a mains adapter. However, some LEDs have a maximum rated current of only 5 mA. You should thus always start testing at the lowest current by setting P1 to maximum resistance. You can easily see from the brightness whether you need more current. If an LED does not light up, it may be defective or connected the wrong way round. Reduce the current to the minimum level before reversing or replacing any LEDs. If you label the polarity of the terminals on the LED tester, you can easily mark the cathode and anode leads of the tested LEDs.

To make it easy to swap the LEDs, you can use an IC socket as a test socket. The selected Zener diodes were chosen to make the tester suitable for red, yellow and green LEDs. Red LEDs have a forward voltage of 1. 6 V to 1. 8 V. The value for yellow LEDs is around 1. 9 V, and with green LEDs the forward voltage can be as high as 2 V. If you also want to test modern blue or white LEDs, you will have to replace the Zener diodes with types having a voltage of 4. 7 V or 5. 1 V. The supply voltage will also have to be increased accordingly for example, by connecting two 9-V batteries in series.

🔗 External reference

The LED tester circuit is designed with simplicity and functionality in mind, allowing for the testing of multiple LEDs simultaneously while ensuring reliable operation even when faced with defective components. The use of a constant-current source through FET T1 is pivotal in maintaining consistent brightness across the tested LEDs, which is crucial for applications requiring uniformity in lighting. The inclusion of Zener diodes not only protects the circuit from potential damage due to incorrect LED polarity but also enhances the testing capability, making it versatile for various LED types. The adjustment feature provided by potentiometer P1 allows for fine-tuning of the current, accommodating different LED specifications and ensuring optimal performance.

Furthermore, the circuit's adaptability to different LED types, including the requirement for higher forward voltages for modern LEDs, underscores its practicality for hobbyists and professionals alike. The ability to use standard components such as IC sockets facilitates ease of use and maintenance, making this LED tester an invaluable tool in electronic projects involving LED displays or indicators. Overall, this LED tester circuit exemplifies an effective solution for ensuring the reliability and functionality of LEDs in various applications.You have to admit that these tiny electronic lamps are handy, and they last almost forever. Around 40 years after Nick Holanyak developed the first LED, they have become just about indispensable. Any self-respecting electronics hobbyist always has a few in his junk box. But before you use LEDs, it`s a good idea to check them out. With a LED tester , you can even do it in the dark! LEDs are available nowadays in all shapes and colors. There are types with clear, colorless packages, while others have colored plastic packages. Many modern types of LEDs need less current than older types. Some of them provide quite a puddle of light if you give them a decent amount of current. When you`re working with used LEDs from the junk box, there`s a good chance that you can`t tell which lead is which any more. (If the leads haven`t been trimmed, the short lead is always the cathode lead and the long lead is the anode lead.

) If you use several LEDs in a display where they all have the same current you naturally want all the LEDs to have the same brightness. But that`s not always the case, even with LEDs of the same type. To save yourself unnecessary soldering work, it`s a good idea to check the LEDs out first. That`s the job of the LED tester described here. This circuit can be used to test up to three LEDs at once, connected in series. You can easily increase that number by using a higher supply voltage. If you do so, you should allow 2. 7 V for each additional LED. The Zener diodes are included in the circuit so it can also be used to test one or two LEDs. Another benefit of the Zeners is that even if one or more of the LEDs are defective or connected with reverse polarity, the remaining ones will light up normally.

That makes it easy to spot suspect LEDs. If you extend the tester to handle more LEDs, you must add another Zener diode for each LED position. The test current that ows through the LEDs is held reasonably constant by FET T1, independent of the number of LEDs being tested.

The FET is used as a constant-current source to keep the circuit as simple as possible. The drawback of this approach is that the tolerance range of FET characteristics is especially large. The type used here even has three versions: A, B and C. We used the B version here so the current through the LEDs can be adjusted using potentiometer P1 over the range of 1 7 mA.

If you need more current, you can use a BF254C instead, but then you will also need a higher supply voltage. For example, you can connect two 9-V batteries in series or power the circuit from a mains adapter. However, some LEDs have a maximum rated current of only 5 mA. You should thus always start testing at the lowest current by setting P1 to maximum resistance. You can easily see from the brightness whether you need more current. If an LED does not light up, it may be defective or connected the wrong way round. Reduce the current to the minimum level before reversing or replacing any LEDs. If you label the polarity of the terminals on the LED tester, you can easily mark the cathode and anode leads of the tested LEDs.

To make it easy to swap the LEDs, you can use an IC socket as a test socket. The selected Zener diodes were chosen to make the tester suitable for red, yellow and green LEDs. Red LEDs have a forward voltage of 1. 6 V to 1. 8 V. The value for yellow LEDs is around 1. 9 V, and with green LEDs the forward voltage can be as high as 2 V. If you also want to test modern blue or white LEDs, you will have to replace the Zener diodes with types having a voltage of 4. 7 V or 5. 1 V. The supply voltage will also have to be increased accordingly for example, by connecting two 9-V batteries in series.

🔗 External reference