lithium ion Battery management circuit for Nokia BL-4C / 5C Li-ION batteries

Nokia BL-4C and BL-5C are 3.7V, 700-1000mAh (various) lithium-ion batteries that have three terminals. These terminals include a positive terminal, a ground, and a BSI (Battery Status Indicator) terminal, which presents a fixed resistance value that needs to be measured to determine the battery type, including its chemistry and characteristics such as capacity. There is an inquiry about existing open-source hardware projects that have developed battery management circuits for these batteries. The question also addresses how to accurately measure the resistance provided by the BSI terminal. It is suggested that a very accurate and stable reference voltage would be necessary; however, if the battery itself serves as the reference voltage, it may vary with the charge status and condition of the battery, raising concerns about its reliability. Additionally, there is a request for recommendations on low-cost battery management ICs that are accessible and easy for hobbyists to use for safely charging such lithium-ion batteries. Previous discussions on resistance measurement mechanisms have been found to be cumbersome, expensive, and requiring manual intervention, making them unsuitable for automated battery type identification. The necessity of a temperature sensor is acknowledged, but there is uncertainty about its application without access to proprietary battery characteristic information for the Nokia battery.

Nokia's BL-4C and BL-5C lithium-ion batteries are designed with three terminals: a positive terminal, a ground terminal, and a BSI terminal. The BSI terminal plays a crucial role in battery management systems by providing a fixed resistance value that can be measured to ascertain the battery's type and characteristics, including its chemistry and capacity. This feature is particularly useful for integrating these batteries into electronic devices that require precise power management.

In developing a battery management circuit for these batteries, it is essential to consider the measurement of the BSI terminal's resistance accurately. A stable reference voltage is critical for this measurement; however, using the battery itself as a reference can introduce variability due to its charge state and overall condition. Therefore, an external reference voltage source, such as a precision voltage reference IC, may be more suitable for consistent measurements.

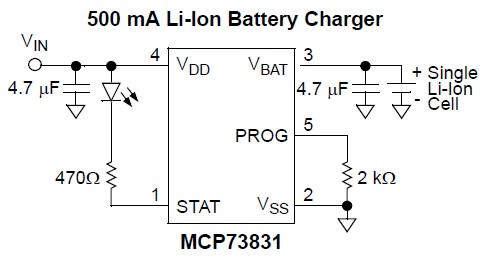

For hobbyists looking to implement a battery management system, several low-cost battery management ICs are available. Options include the TP4056 for charging single-cell lithium-ion batteries, which features overcharge protection and can be easily sourced. The BQ24074 from Texas Instruments is another viable option, offering integrated power path management and the ability to handle different charging profiles.

In terms of temperature monitoring, incorporating a temperature sensor into the battery management system is advisable to ensure safe operation. The sensor can provide critical data to prevent overheating during charging and discharging cycles. However, without access to proprietary information about the Nokia battery's thermal characteristics, the implementation of the temperature sensor may be limited to general safety thresholds.

For further exploration, it is recommended to search for open-source projects that focus on battery management systems tailored for lithium-ion batteries, as these can provide valuable insights and practical guidance for hobbyists.Nokia BL-4C / BL-5C are 3. 7V, 700-1000mAh ( variants ) Lithium-ion batteries, have 3 terminals, as explained here, for battery positive-terminal, ground, and a terminal (BSI) which I believe presents a fixed resistance value, that needs to be measured, to determine battery-type (chemistry, characteristics including capacity etc. ) Is anyone aware of any existing open-source hardware project, that has built battery-management circuit around such batteries (PS> In my searches so far, I`ve not come across any such project). How exactly, can one accurately measure the resistance offered by BSI terminal of the battery A very accurate and stable reference voltage would be required, I believe - but if the battery itself is the source of such reference voltage, it could vary with charge-status and condition of battery, so how could it serve as a good reference What would be some low-cost battery-management IC`s that are not too difficult to source or work with, for hobbyists, which can be used to charge such Li-ION batteries safely Have found this question here related to `resistance measurement`, but the mechanisms described are far too cumbersome, expensive & require manual intervention, to be useful in automated battery-type identification.

OTOH, it is possible that I`ve completely misunderstood the purpose of the BSI terminal. As for whether "temp sensor" is needed, I think the answer is YES, based on this. However, the question then becomes, without access to proprietary battery characteristics information of this Nokia battery, what can one do with the temp-sensor 🔗 External reference

Nokia's BL-4C and BL-5C lithium-ion batteries are designed with three terminals: a positive terminal, a ground terminal, and a BSI terminal. The BSI terminal plays a crucial role in battery management systems by providing a fixed resistance value that can be measured to ascertain the battery's type and characteristics, including its chemistry and capacity. This feature is particularly useful for integrating these batteries into electronic devices that require precise power management.

In developing a battery management circuit for these batteries, it is essential to consider the measurement of the BSI terminal's resistance accurately. A stable reference voltage is critical for this measurement; however, using the battery itself as a reference can introduce variability due to its charge state and overall condition. Therefore, an external reference voltage source, such as a precision voltage reference IC, may be more suitable for consistent measurements.

For hobbyists looking to implement a battery management system, several low-cost battery management ICs are available. Options include the TP4056 for charging single-cell lithium-ion batteries, which features overcharge protection and can be easily sourced. The BQ24074 from Texas Instruments is another viable option, offering integrated power path management and the ability to handle different charging profiles.

In terms of temperature monitoring, incorporating a temperature sensor into the battery management system is advisable to ensure safe operation. The sensor can provide critical data to prevent overheating during charging and discharging cycles. However, without access to proprietary information about the Nokia battery's thermal characteristics, the implementation of the temperature sensor may be limited to general safety thresholds.

For further exploration, it is recommended to search for open-source projects that focus on battery management systems tailored for lithium-ion batteries, as these can provide valuable insights and practical guidance for hobbyists.Nokia BL-4C / BL-5C are 3. 7V, 700-1000mAh ( variants ) Lithium-ion batteries, have 3 terminals, as explained here, for battery positive-terminal, ground, and a terminal (BSI) which I believe presents a fixed resistance value, that needs to be measured, to determine battery-type (chemistry, characteristics including capacity etc. ) Is anyone aware of any existing open-source hardware project, that has built battery-management circuit around such batteries (PS> In my searches so far, I`ve not come across any such project). How exactly, can one accurately measure the resistance offered by BSI terminal of the battery A very accurate and stable reference voltage would be required, I believe - but if the battery itself is the source of such reference voltage, it could vary with charge-status and condition of battery, so how could it serve as a good reference What would be some low-cost battery-management IC`s that are not too difficult to source or work with, for hobbyists, which can be used to charge such Li-ION batteries safely Have found this question here related to `resistance measurement`, but the mechanisms described are far too cumbersome, expensive & require manual intervention, to be useful in automated battery-type identification.

OTOH, it is possible that I`ve completely misunderstood the purpose of the BSI terminal. As for whether "temp sensor" is needed, I think the answer is YES, based on this. However, the question then becomes, without access to proprietary battery characteristics information of this Nokia battery, what can one do with the temp-sensor 🔗 External reference