Litter Box with 12V pc fan

Not every new use of technology requires a microcontroller. This one uses a 12 volt computer fan from CompUSA, a snap close food box from Walmart, some PVC pipe from Home Depot, and a large plastic storage container from Big Lots. The food storage box has its lid screwed to the container, with holes drilled through the lids of both. A one-inch round hole is drilled in the base (now on top) of the storage box, and a 12 volt DC wall-wart powers the fan. A large entry hole is cut in the lid of the box. This type of entry keeps most of the litter from migrating out. Sections of 1 inch PVC pipe are cut and jammed together to route the odors out a nearby window. Changing the litter out once a month works just fine. At least, the cat is not complaining. Usually, there is no smell at all from this system due to the constant outflow of air and really low humidity here in Arizona.

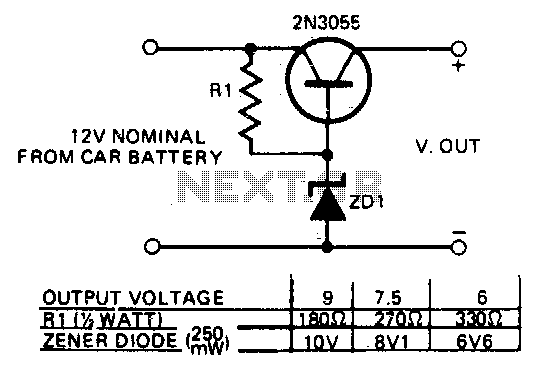

The described system utilizes a 12-volt DC computer fan as a primary component to facilitate air circulation within a modified storage solution for cat litter management. The construction involves a snap-close food box, which serves as a containment unit for the cat litter, effectively minimizing odor escape and litter migration. The fan is powered by a standard 12-volt DC wall adapter, which is a common power source for low-voltage electronics, ensuring a safe and efficient operation.

The integration of PVC pipe sections allows for the effective routing of odors to an external environment, thus enhancing the overall functionality of the litter box. The design includes a strategically placed one-inch hole at the top of the storage box, which serves as an exhaust for the fan, facilitating continuous airflow. This design choice is essential in maintaining a low-humidity environment within the box, which is critical for odor control, especially in arid climates such as Arizona.

The use of a large entry hole in the lid of the food storage box aids in preventing litter spillage while still allowing easy access for the cat. The assembly is constructed in a manner that ensures durability and ease of maintenance, with the fan and the PVC piping designed for simple disassembly when necessary. The combination of these components results in a system that effectively manages pet waste with minimal odor, thus providing a more pleasant living environment for both the pet and the owner. Regular maintenance, such as changing the litter once a month, is sufficient to keep the system functioning optimally.Not every new use of technology requires a microcontroller. This one uses a 12 volt computer fan from CompUSA, a snap close food box from Walmart, some PVC pipe from Home Depot, and a large plastic storage container from Big Lots.e food storage box whose lid is screwed to the container and holes drilled thru the lids of both. A one inch round hole is drilled in the base (now on top) of the storage box and a 12 volt dc wall-wart powers the fan.

A large entry hole is cut in the lid of the box. This type of entry keeps most of the litter from migrating out. Sections of 1 inch pvc pipe are cut and jammed together to route the odors out a nearby window. Changing the litter out once a month works just fine. At least, the cat is not complaining. Usually, there is no smell at all from this system do to the constant outflow of air and really low humidity here in Arizona. 🔗 External reference

The described system utilizes a 12-volt DC computer fan as a primary component to facilitate air circulation within a modified storage solution for cat litter management. The construction involves a snap-close food box, which serves as a containment unit for the cat litter, effectively minimizing odor escape and litter migration. The fan is powered by a standard 12-volt DC wall adapter, which is a common power source for low-voltage electronics, ensuring a safe and efficient operation.

The integration of PVC pipe sections allows for the effective routing of odors to an external environment, thus enhancing the overall functionality of the litter box. The design includes a strategically placed one-inch hole at the top of the storage box, which serves as an exhaust for the fan, facilitating continuous airflow. This design choice is essential in maintaining a low-humidity environment within the box, which is critical for odor control, especially in arid climates such as Arizona.

The use of a large entry hole in the lid of the food storage box aids in preventing litter spillage while still allowing easy access for the cat. The assembly is constructed in a manner that ensures durability and ease of maintenance, with the fan and the PVC piping designed for simple disassembly when necessary. The combination of these components results in a system that effectively manages pet waste with minimal odor, thus providing a more pleasant living environment for both the pet and the owner. Regular maintenance, such as changing the litter once a month, is sufficient to keep the system functioning optimally.Not every new use of technology requires a microcontroller. This one uses a 12 volt computer fan from CompUSA, a snap close food box from Walmart, some PVC pipe from Home Depot, and a large plastic storage container from Big Lots.e food storage box whose lid is screwed to the container and holes drilled thru the lids of both. A one inch round hole is drilled in the base (now on top) of the storage box and a 12 volt dc wall-wart powers the fan.

A large entry hole is cut in the lid of the box. This type of entry keeps most of the litter from migrating out. Sections of 1 inch pvc pipe are cut and jammed together to route the odors out a nearby window. Changing the litter out once a month works just fine. At least, the cat is not complaining. Usually, there is no smell at all from this system do to the constant outflow of air and really low humidity here in Arizona. 🔗 External reference