Low-Power Car/Bike USB Charger

An efficient USB charger designed to operate from a 12V car battery, achieving up to 89% efficiency and capable of charging USB devices at currents up to 525mA. It does not drain the battery if left permanently connected, provided the USB device is unplugged. This device features two significant advantages: high efficiency and low standby current of just 160 µA, which is considerably lower than the self-discharge current of most lead-acid batteries. This allows for permanent connection without significantly depleting the battery. This capability is particularly useful for applications such as connecting a 12V-to-5V USB charger directly to a motorcycle battery without voiding the warranty, as long as the quiescent current is below 1mA to prevent battery drainage. Although many USB car chargers are available, finding one with low enough quiescent current for continuous battery attachment is challenging. A typical charger may draw 13mA on standby, largely due to integrated power LEDs. As cigarette lighter sockets are only powered when the engine is running, there is little incentive for manufacturers to minimize quiescent current. This project allows for the use of various connector types, often spade or eyelet lugs, enhancing versatility. While this application may seem specific, a low-quiescent current 12V DC to 5V DC converter has broader uses, such as in remote monitoring stations powered by a 12V SLA battery and supplemented by solar panels. These stations typically require a 3.3V-5V supply for microcontrollers and other circuitry, which may occasionally demand higher currents. This charger can provide up to 500mA while maintaining low battery consumption during light loads, ensuring minimal waste of battery power.

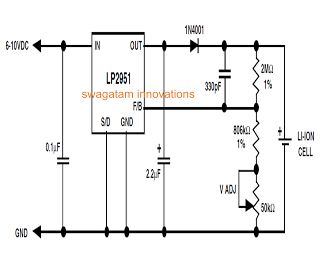

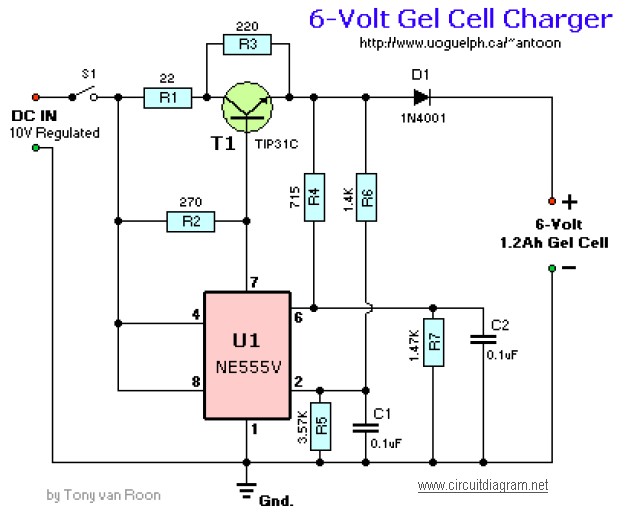

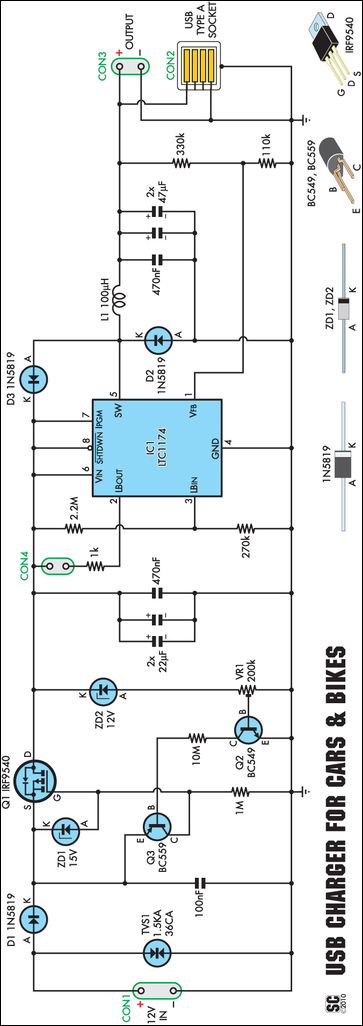

The design of the USB charger incorporates a DC-DC buck converter topology, which efficiently steps down the 12V input from the car battery to the required 5V output for USB devices. The circuit typically includes a switching regulator, an inductor, and capacitors to filter the output voltage, ensuring stable operation. The high efficiency of up to 89% is achieved through the use of a synchronous rectification method, where MOSFETs replace the traditional diodes, significantly reducing power loss during the switching process.

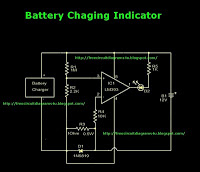

In terms of standby current management, the circuit employs a low-power microcontroller or comparator that monitors the USB output. When no load is detected, the controller can enter a low-power sleep mode, effectively reducing the quiescent current to below 1mA. This feature is critical for applications where the device remains connected for extended periods without active use, such as in remote monitoring stations.

The output stage of the charger is designed to handle a maximum current of 525mA, with overcurrent protection implemented to prevent damage to both the charger and the connected devices. Additionally, thermal management is considered; the components are rated to operate within safe temperature limits to ensure reliability and longevity.

Overall, this USB charger serves as a practical solution for powering devices in automotive and remote applications, combining efficiency, low standby consumption, and versatility in connector options. Its design principles can be adapted for various use cases, making it a valuable component in both consumer electronics and specialized remote monitoring systems.Looking for an efficient USB charger that can operate from a 12V car battery This unit functions at up to 89% efficiency and can charge USB devices at currents up to 525mA. Best of all, it won`t flatten the battery if it`s left permanently connected, as long as you remember to unplug the USB device.

There are lots of USB chargers on the market bu t this device has two stand-out features: high efficiency and low standby current. In fact, its standby current is just 160 A, a figure that`s well below the self-discharge current of most lead-acid batteries. This means that you can leave the device permanently connected and it will not cause that battery to go flat (or at least, not much faster than it would of its own accord).

Why is this useful Well, in September 2009`s Ask SILICON CHIP section, D. E. of Ainslie, ACT asked if it was possible to connect a 12V-to-5V USB charger directly to the battery on a motorbike. His reason for wanting to do this is that doing anything else might void the warranty. Our reply was that it is possible but that it would need to have a quiescent current (IQ) of less than 1mA to avoid draining the battery between uses.

While USB car chargers are cheap and plentiful, finding one with a low enough quiescent current for permanent battery attachment is difficult. Even those marketed as low idle power devices don`t specify how much current they draw on standby. We tested a regular charger and found that it consumed 13mA with no load. Like many others, it has an integrated power LED and that would contribute significantly to the standby current consumption.

However, since the cigarette lighter socket is only powered when the engine is running, there is no real reason for the designers of these car supplies to keep the quiescent current low. Cigarette lighter plugs are also pretty lousy DC connectors. They often don`t fit well and can easily fall out. With this project, you can use whatever type of connector is most convenient. In many cases, this will mean input wires terminated in spade or eyelet lugs. While this may seem like a very specific application, there are many other uses for a low-quiescent current 12V DC to 5V DC converter.

For example, remote monitoring stations often run from a 12V SLA battery topped up by a solar panel. These stations invariably contain a microcontroller and other circuitry which needs a 3. 3V-5V supply. The current consumption in these devices will be low most of the time but occasionally the microcontroller will wake up and activate a radio module or other circuitry which can draw more current. This charger can deliver that current up to 500mA while still being miserly with battery power when the load is light.

In addition, because its efficiency is high (up to 89%), hardly any battery power is wasted even when the load is drawing 500mA. 🔗 External reference

The design of the USB charger incorporates a DC-DC buck converter topology, which efficiently steps down the 12V input from the car battery to the required 5V output for USB devices. The circuit typically includes a switching regulator, an inductor, and capacitors to filter the output voltage, ensuring stable operation. The high efficiency of up to 89% is achieved through the use of a synchronous rectification method, where MOSFETs replace the traditional diodes, significantly reducing power loss during the switching process.

In terms of standby current management, the circuit employs a low-power microcontroller or comparator that monitors the USB output. When no load is detected, the controller can enter a low-power sleep mode, effectively reducing the quiescent current to below 1mA. This feature is critical for applications where the device remains connected for extended periods without active use, such as in remote monitoring stations.

The output stage of the charger is designed to handle a maximum current of 525mA, with overcurrent protection implemented to prevent damage to both the charger and the connected devices. Additionally, thermal management is considered; the components are rated to operate within safe temperature limits to ensure reliability and longevity.

Overall, this USB charger serves as a practical solution for powering devices in automotive and remote applications, combining efficiency, low standby consumption, and versatility in connector options. Its design principles can be adapted for various use cases, making it a valuable component in both consumer electronics and specialized remote monitoring systems.Looking for an efficient USB charger that can operate from a 12V car battery This unit functions at up to 89% efficiency and can charge USB devices at currents up to 525mA. Best of all, it won`t flatten the battery if it`s left permanently connected, as long as you remember to unplug the USB device.

There are lots of USB chargers on the market bu t this device has two stand-out features: high efficiency and low standby current. In fact, its standby current is just 160 A, a figure that`s well below the self-discharge current of most lead-acid batteries. This means that you can leave the device permanently connected and it will not cause that battery to go flat (or at least, not much faster than it would of its own accord).

Why is this useful Well, in September 2009`s Ask SILICON CHIP section, D. E. of Ainslie, ACT asked if it was possible to connect a 12V-to-5V USB charger directly to the battery on a motorbike. His reason for wanting to do this is that doing anything else might void the warranty. Our reply was that it is possible but that it would need to have a quiescent current (IQ) of less than 1mA to avoid draining the battery between uses.

While USB car chargers are cheap and plentiful, finding one with a low enough quiescent current for permanent battery attachment is difficult. Even those marketed as low idle power devices don`t specify how much current they draw on standby. We tested a regular charger and found that it consumed 13mA with no load. Like many others, it has an integrated power LED and that would contribute significantly to the standby current consumption.

However, since the cigarette lighter socket is only powered when the engine is running, there is no real reason for the designers of these car supplies to keep the quiescent current low. Cigarette lighter plugs are also pretty lousy DC connectors. They often don`t fit well and can easily fall out. With this project, you can use whatever type of connector is most convenient. In many cases, this will mean input wires terminated in spade or eyelet lugs. While this may seem like a very specific application, there are many other uses for a low-quiescent current 12V DC to 5V DC converter.

For example, remote monitoring stations often run from a 12V SLA battery topped up by a solar panel. These stations invariably contain a microcontroller and other circuitry which needs a 3. 3V-5V supply. The current consumption in these devices will be low most of the time but occasionally the microcontroller will wake up and activate a radio module or other circuitry which can draw more current. This charger can deliver that current up to 500mA while still being miserly with battery power when the load is light.

In addition, because its efficiency is high (up to 89%), hardly any battery power is wasted even when the load is drawing 500mA. 🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713