NC visible laser modulation driver circuit

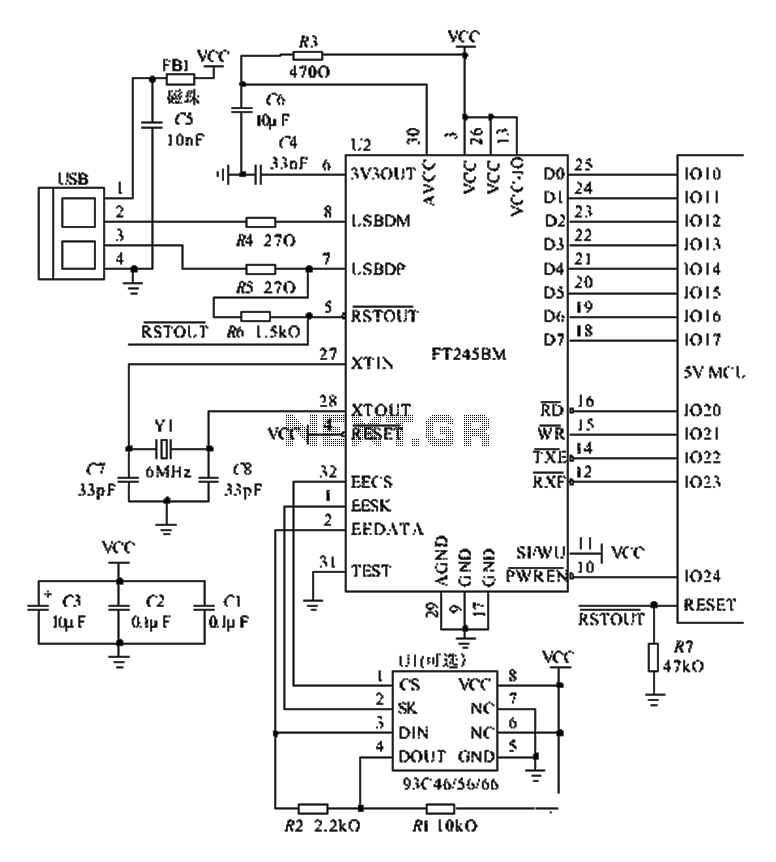

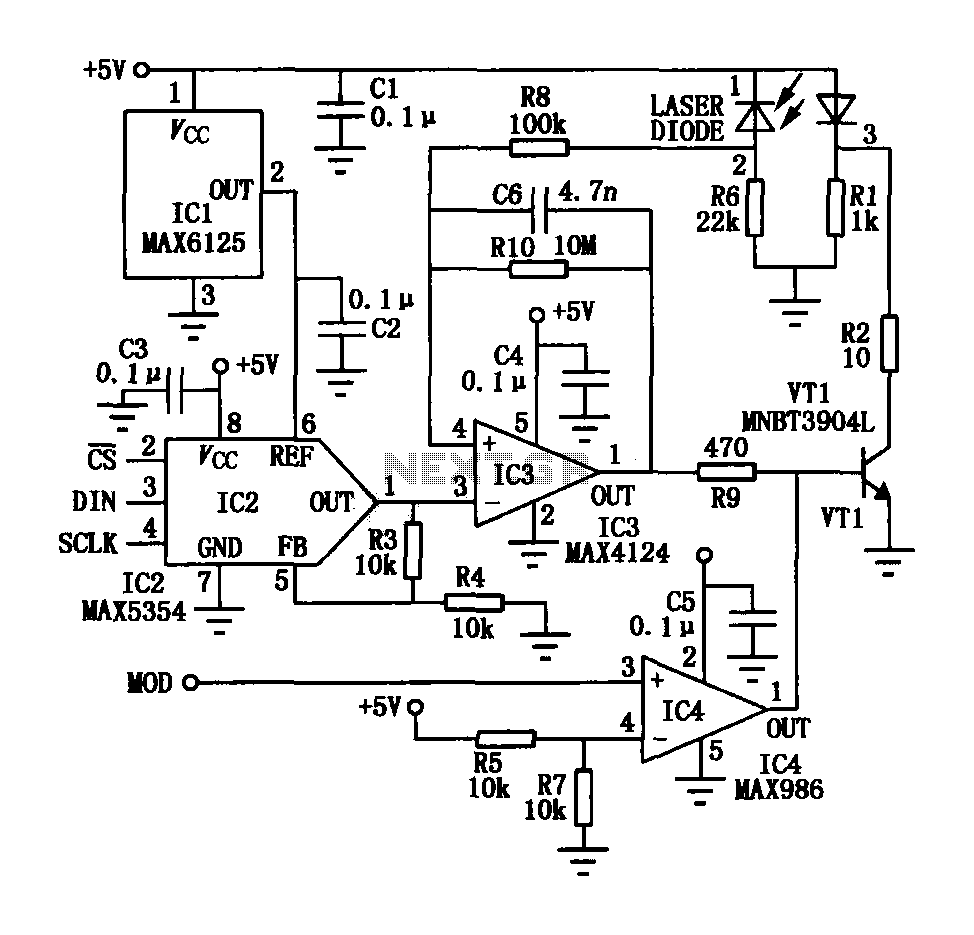

The laser tube drive circuit typically incorporates a photodiode that generates a laser beam proportional to the intensity (optical power) of the current. However, this type of photocell is generally slow and unable to track modulation effectively, particularly for peak light laser tube power. Consequently, this drive circuit monitors the average optical power to control the laser generator. The visible laser modulation driver circuit includes a digital-to-analog converter (DAC) with a 3-wire serial interface, which is used to maintain a constant average optical power output from the visible light laser tube. Additionally, there is a separate digital input line (MOD) and an open-drain output from a comparator (IC4) and transistor (VT1), which deliver pulses to the laser diode (VD1) for digital communications.

The laser tube drive circuit is designed to ensure stable operation of the laser system by continuously monitoring and adjusting the optical power output. The use of a photodiode allows for the detection of the laser beam intensity, providing feedback for the control system. However, due to the slow response time of the photodiode, it is not suitable for applications requiring rapid modulation of the laser output.

To address this limitation, the design incorporates a digital-to-analog converter (DAC) that translates digital signals into analog control voltages, thereby enabling precise adjustments to the laser power. The 3-wire serial interface facilitates communication between the DAC and the controlling microcontroller or digital signal processor, allowing for seamless integration into automated systems.

The visible laser modulation driver circuit is equipped with a separate digital input line (MOD) that can be used to trigger modulation events. The comparator (IC4) serves to compare the feedback signal from the photodiode with a reference voltage, ensuring that the output remains within specified limits. The open-drain output configuration allows for flexibility in interfacing with various components, including the transistor (VT1) that acts as a switch to pulse the laser diode (VD1) based on the digital commands received.

This architecture not only enhances the performance of the laser tube drive circuit but also allows for effective digital communication, making it suitable for applications in laser marking, engraving, and other industrial processes where precise control of laser output is crucial. The overall design emphasizes stability, responsiveness, and adaptability to varying operational demands.In the laser tube drive circuit are often provided with a photodiode, which generates a laser beam is proportional to the intensity (optical power) of the current, but in response to this type of photocell mostly relatively slow, generally can not track modulation peak light laser tube power. Therefore, this drive circuit is achieved by monitoring the average optical power to control the laser generator. NC visible laser modulation driver circuit is shown, which includes a digital to analog converter 10 3-wire serial interface (DAC), a visible light laser tube is used to control the output of a constant average optical power; a separate digital input line (MOD), an open-drain output by a comparator (IC4) and VTl, is fed to the laser diode VD1 pulse, digital communications.

The laser tube drive circuit is designed to ensure stable operation of the laser system by continuously monitoring and adjusting the optical power output. The use of a photodiode allows for the detection of the laser beam intensity, providing feedback for the control system. However, due to the slow response time of the photodiode, it is not suitable for applications requiring rapid modulation of the laser output.

To address this limitation, the design incorporates a digital-to-analog converter (DAC) that translates digital signals into analog control voltages, thereby enabling precise adjustments to the laser power. The 3-wire serial interface facilitates communication between the DAC and the controlling microcontroller or digital signal processor, allowing for seamless integration into automated systems.

The visible laser modulation driver circuit is equipped with a separate digital input line (MOD) that can be used to trigger modulation events. The comparator (IC4) serves to compare the feedback signal from the photodiode with a reference voltage, ensuring that the output remains within specified limits. The open-drain output configuration allows for flexibility in interfacing with various components, including the transistor (VT1) that acts as a switch to pulse the laser diode (VD1) based on the digital commands received.

This architecture not only enhances the performance of the laser tube drive circuit but also allows for effective digital communication, making it suitable for applications in laser marking, engraving, and other industrial processes where precise control of laser output is crucial. The overall design emphasizes stability, responsiveness, and adaptability to varying operational demands.In the laser tube drive circuit are often provided with a photodiode, which generates a laser beam is proportional to the intensity (optical power) of the current, but in response to this type of photocell mostly relatively slow, generally can not track modulation peak light laser tube power. Therefore, this drive circuit is achieved by monitoring the average optical power to control the laser generator. NC visible laser modulation driver circuit is shown, which includes a digital to analog converter 10 3-wire serial interface (DAC), a visible light laser tube is used to control the output of a constant average optical power; a separate digital input line (MOD), an open-drain output by a comparator (IC4) and VTl, is fed to the laser diode VD1 pulse, digital communications.

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713