NiCd NiMH Battery Charger

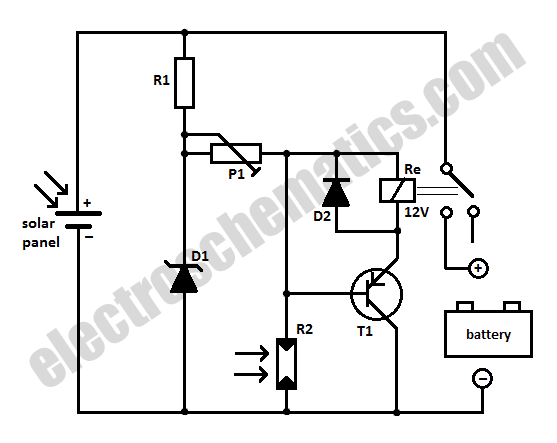

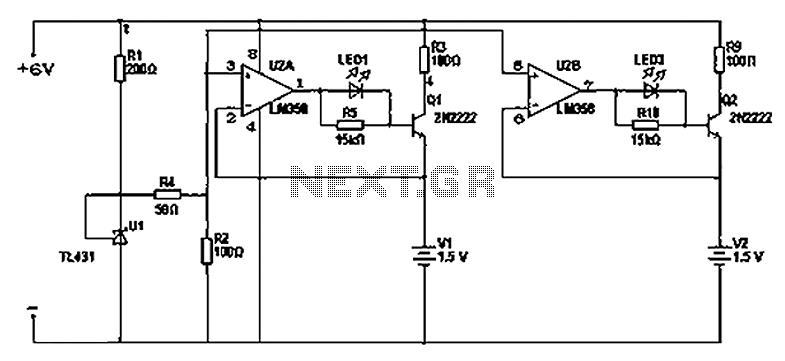

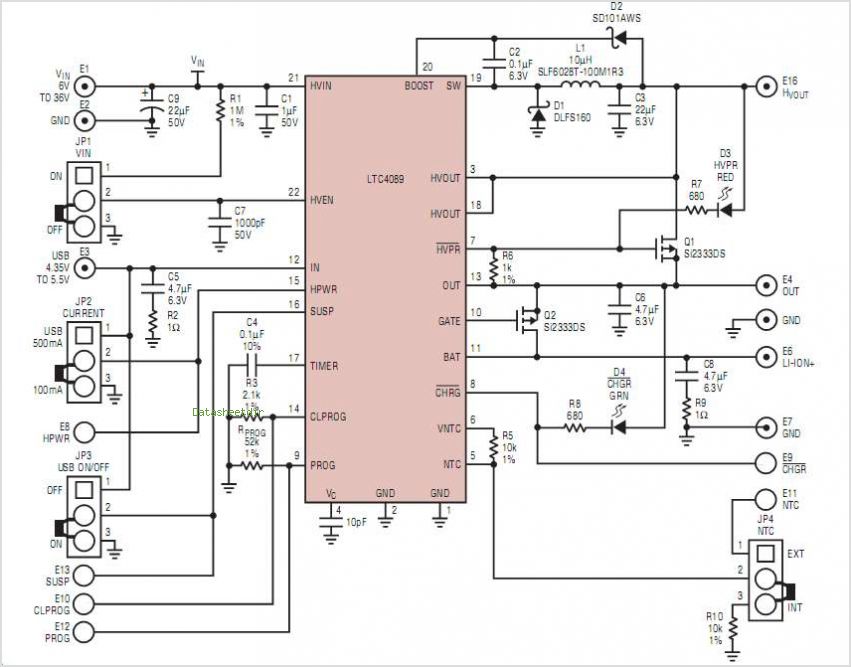

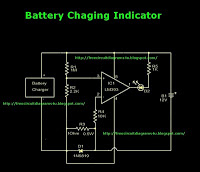

The following diagram represents the schematic of a Ni-CAD battery charger circuit, which features current and voltage limiting to prolong the battery's lifespan. The lamp L1 will illuminate brightly while the LED will be off when the battery is low and charging is in progress. However, the LED will be very bright at other times. This battery charger circuit is designed for rechargeable lithium batteries. Charging is accomplished with a constant current of 60 mA for AA cells, up to a cutoff voltage of 2.4V per cell, at which point charging must be terminated. The charging system is designed for multi-cell battery packs consisting of 2 to 6 series-connected cells. Additionally, this schematic diagram illustrates a 12V Ni-CAD battery charger with a charging rate of 200 mA per hour. This charger operates at 75 mA until the battery is fully charged, then it reduces the current to a trickle rate. It can fully recharge a dead or unpowered battery within 4 hours. The schematic also includes a lead-acid battery charger circuit, which provides an initial voltage of 2.5V per cell at 25°C to quickly charge the battery. The charging current decreases as the battery charges, and when the current drops to 180 mA, the charging circuit reduces the output voltage. Furthermore, this is the schematic diagram of a solar-powered mobile phone battery charger, designed to charge the battery from a source with a lower voltage. It should not be used to charge batteries with the same or lower voltage than that generated by the solar panel. For proper operation, this battery charger circuit is regulated and adjustable, enabling it to charge most Ni-CAD batteries. This circuit is compatible with single cells or multi-battery cells connected in series or parallel, with a maximum battery voltage of 18V. Power transistors Q1 and Q2 are configured as series regulators.

This schematic diagram showcases a versatile battery charging solution, accommodating various types of rechargeable batteries. The Ni-CAD charger is particularly designed to maintain battery health through effective current and voltage regulation. The inclusion of lamp L1 serves as a visual indicator of charging status, enhancing user awareness of the charging process. The LED's behavior provides additional feedback, indicating when the battery is in a low state and actively charging.

The circuit's design for multi-cell packs allows for flexibility in battery configurations, supporting 2 to 6 cells in series, which is essential for applications requiring higher voltages. The specified charging current of 60 mA for AA cells ensures that the batteries are charged safely without overheating, while the cutoff voltage of 2.4V is critical for preventing overcharging, which can lead to reduced battery life or damage.

The 12V Ni-CAD charger operates effectively at a charging rate of 200 mA per hour, with the ability to reduce the charging current to a trickle rate once the battery reaches full charge. This feature is particularly beneficial for maintaining battery health over extended periods without causing damage due to overcharging.

The lead-acid battery charger circuit is optimized for rapid charging with an initial voltage of 2.5V per cell, suitable for quick recovery of depleted batteries. The automatic reduction of charging current as the battery approaches full charge is a key safety feature that prevents excessive current flow, thereby enhancing the longevity of the battery.

The solar-powered mobile phone battery charger is designed to leverage renewable energy sources, making it an environmentally friendly option. The design considerations ensure that it operates effectively only with compatible voltage levels, preventing potential damage to the batteries being charged.

Overall, this comprehensive battery charging circuit design is adaptable to various battery technologies and configurations, providing a robust solution for both consumer and industrial applications. The integration of adjustable regulation and safety features makes it suitable for a wide range of battery management scenarios.The following diagram is the schematic diagram of Ni-CAD Battery Charger circuit which featured with current and voltage limiting to keep the battery lifetime. The lamp L1 will be light brightly and the LED will be out when the battery is low and battery charging in progress, but the LED is very bright and the.

This battery charger circuit is use d for rechargable lithium battery. Charging is accomplished with a constant current of 60 mA for AA cells to a cutoff of 2. 4V per cell, at which point the charge must be terminated. The charging system shown is designed for multi-cell battery pack of 2 to 6 series connected cell. The following diagram is the schematic diagram of 12V NiCAD battery charger with charging rate of 200mA/Hour. This NiCAD battery charger circuit charges the battery at 75 mA until the battery is charged, then it reduces the current to a trickle rate.

It will fully recharge a dead/unpowered battery in 4 hours and the battery. The following diagram is the circuit diagram of Lead-Acid battery charger. This circuit provides an initial voltage of 2. 5 V per cell at 25 ƒ to quickly charge the battery. The charging current decreases as the battery is charging, and when the current drops to 180 mA, the charging circuit reduces the output voltage of. This is the schematic diagram of solar powered mobile phone battery charger. The circuit is designed to charge the battery from a source with a lower voltage. Do not use it to charge the battery with the same or lower voltage than the voltage which is generated by the solar panel.

For proper operation of. This battery charger circuit is regulated and adjustable to make this circuit able to charge the mosto NiCAD battery. This circuit will work for single cell or multi battery cell which connected with series/parallel connection.

The maximum voltage of the batteries should be 18V maximum. Power transistors Q1 and Q2 are connected as series regulators. 🔗 External reference

This schematic diagram showcases a versatile battery charging solution, accommodating various types of rechargeable batteries. The Ni-CAD charger is particularly designed to maintain battery health through effective current and voltage regulation. The inclusion of lamp L1 serves as a visual indicator of charging status, enhancing user awareness of the charging process. The LED's behavior provides additional feedback, indicating when the battery is in a low state and actively charging.

The circuit's design for multi-cell packs allows for flexibility in battery configurations, supporting 2 to 6 cells in series, which is essential for applications requiring higher voltages. The specified charging current of 60 mA for AA cells ensures that the batteries are charged safely without overheating, while the cutoff voltage of 2.4V is critical for preventing overcharging, which can lead to reduced battery life or damage.

The 12V Ni-CAD charger operates effectively at a charging rate of 200 mA per hour, with the ability to reduce the charging current to a trickle rate once the battery reaches full charge. This feature is particularly beneficial for maintaining battery health over extended periods without causing damage due to overcharging.

The lead-acid battery charger circuit is optimized for rapid charging with an initial voltage of 2.5V per cell, suitable for quick recovery of depleted batteries. The automatic reduction of charging current as the battery approaches full charge is a key safety feature that prevents excessive current flow, thereby enhancing the longevity of the battery.

The solar-powered mobile phone battery charger is designed to leverage renewable energy sources, making it an environmentally friendly option. The design considerations ensure that it operates effectively only with compatible voltage levels, preventing potential damage to the batteries being charged.

Overall, this comprehensive battery charging circuit design is adaptable to various battery technologies and configurations, providing a robust solution for both consumer and industrial applications. The integration of adjustable regulation and safety features makes it suitable for a wide range of battery management scenarios.The following diagram is the schematic diagram of Ni-CAD Battery Charger circuit which featured with current and voltage limiting to keep the battery lifetime. The lamp L1 will be light brightly and the LED will be out when the battery is low and battery charging in progress, but the LED is very bright and the.

This battery charger circuit is use d for rechargable lithium battery. Charging is accomplished with a constant current of 60 mA for AA cells to a cutoff of 2. 4V per cell, at which point the charge must be terminated. The charging system shown is designed for multi-cell battery pack of 2 to 6 series connected cell. The following diagram is the schematic diagram of 12V NiCAD battery charger with charging rate of 200mA/Hour. This NiCAD battery charger circuit charges the battery at 75 mA until the battery is charged, then it reduces the current to a trickle rate.

It will fully recharge a dead/unpowered battery in 4 hours and the battery. The following diagram is the circuit diagram of Lead-Acid battery charger. This circuit provides an initial voltage of 2. 5 V per cell at 25 ƒ to quickly charge the battery. The charging current decreases as the battery is charging, and when the current drops to 180 mA, the charging circuit reduces the output voltage of. This is the schematic diagram of solar powered mobile phone battery charger. The circuit is designed to charge the battery from a source with a lower voltage. Do not use it to charge the battery with the same or lower voltage than the voltage which is generated by the solar panel.

For proper operation of. This battery charger circuit is regulated and adjustable to make this circuit able to charge the mosto NiCAD battery. This circuit will work for single cell or multi battery cell which connected with series/parallel connection.

The maximum voltage of the batteries should be 18V maximum. Power transistors Q1 and Q2 are connected as series regulators. 🔗 External reference