Open Loop Speed Control of a DC Motor via 8255 Controller

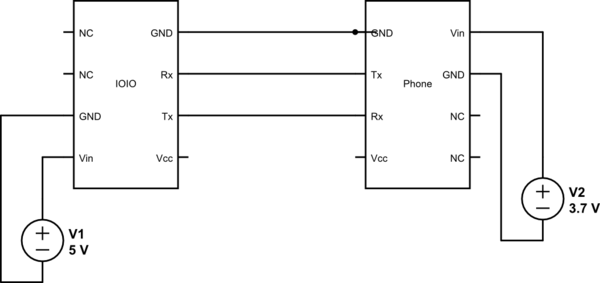

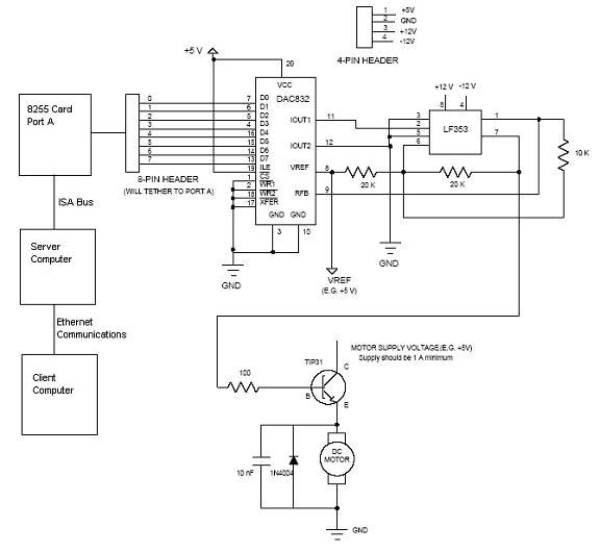

Open loop speed control of a DC motor is implemented using the 8255 Digital I/O Controller chip in conjunction with a TCP/IP server-client application programmed in Visual Basic. The DAC0832 chip serves as the Digital to Analog Converter. This project establishes open loop control of a DC motor utilizing a power amplifier, a digital to analog converter, an 8255 digital interface card, a client PC, and a server PC. The circuit controlled by the server computer via the 8255 digital interface regulates the speed of the DC motor by adjusting the voltage supplied to the base of the power amplifier. The voltage supplied to the motor from the power source ranges from 0 to +5V. The power amplifier circuit is responsible for delivering the necessary current to operate the motor. The client computer interfaces with the server computer through Ethernet communication, providing a graphical user interface (GUI) for motor speed control. Although multiple client computers can connect to the server, only one is utilized for this application. The Visual Basic code employs the Winsock component to facilitate server/client operations. The system incorporates several electro-mechanical components: an 8255 card that connects the server PC with the DC motor control circuits. The main function of the 8255 card is to serve as an interface between the server PC and the DC motor control circuits. Further information on the construction and operation of the 8255 card can be referenced in additional resources. The DAC-LF353 operational amplifier circuit ensures the correct voltage is supplied to the TIP31, which regulates the current from the power supply. The circuit is designed to output voltage levels ranging from 0V to +5V. The TIP31 functions as a power amplifier, allowing current to flow from the collector to the emitter pin in proportion to the voltage at the base pin. The velocity command (in RPM) is transmitted from the client to the server via WinSock TCP/IP. This command is converted into a digital value and sent to the DAC through Port A of the 8255 digital interface. Motor current is monitored across the motor terminals using a 100 Ohm resistor wired in series, serving as a tachometer. The system enables remote access to expensive and rare equipment, allowing users who cannot justify purchasing such equipment to utilize it through agreements with host organizations. Organizations contemplating the acquisition of costly equipment may offset expenses by renting time on the machinery over the Internet, creating a global customer base. In large facilities, such as power plants, applications necessitating constant control and monitoring may exist. These facilities may operate networks consisting of multiple server and client computers. A pertinent example of server-client architecture in a control and monitoring context is vibration-monitoring systems in industrial plants, which use accelerometers attached to critical components to preemptively identify faults. Numerous data acquisition modules and server PCs continuously collect data, perform FFT analysis, and conduct trend evaluations. The client computer retrieves this information to make decisions, such as issuing alarms or shutting down affected plant sections.

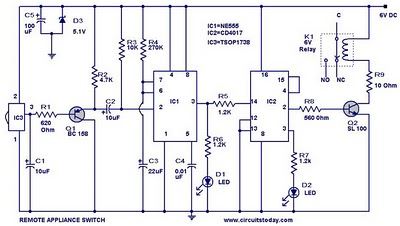

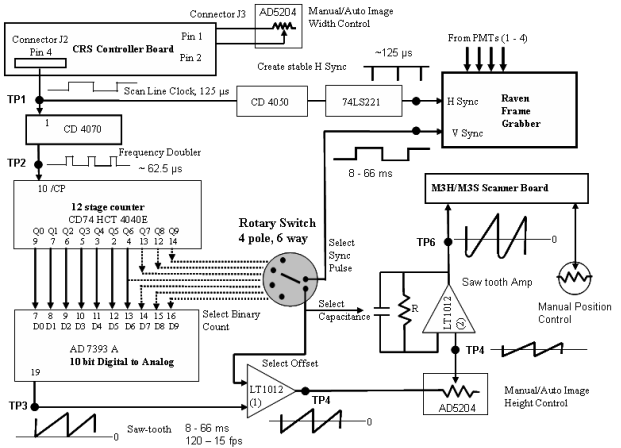

The schematic for this open loop speed control system integrates several key components that work together to achieve precise motor control. The 8255 Digital I/O Controller facilitates communication between the server and the motor control circuitry. It features multiple ports that allow for parallel data transfer, enabling real-time adjustments to motor speed based on user input from the client PC. The DAC0832 digital-to-analog converter translates digital commands from the 8255 into an analog voltage signal, which directly influences the base voltage of the TIP31 power amplifier.

The TIP31 functions as a current amplifier, controlling the motor’s power supply based on the voltage received. The operational amplifier (DAC-LF353) is crucial in maintaining stable voltage levels, ensuring that fluctuations do not affect motor performance. The power amplifier circuit is designed to handle the current requirements of the motor while providing a linear response to the input voltage.

For monitoring, a 100 Ohm resistor serves as a current sensing element, allowing for the measurement of motor current. This feedback loop is essential for maintaining the desired speed and for implementing safety features such as overload protection.

In terms of network architecture, the system leverages TCP/IP protocols to facilitate communication between the server and client PCs. The Winsock component in Visual Basic is instrumental in establishing this connection, allowing for seamless data transmission and control commands. This setup can be expanded with multiple clients, enhancing the system's scalability and flexibility in various industrial applications.

Overall, this circuit design exemplifies a robust approach to DC motor control, combining digital interfacing, analog signal processing, and networked communication to achieve efficient and effective motor management in a variety of operational settings.Open Loop Speed Control of a DC Motor via 8255 Digital I/O Controller chip using TCP/IP Server-Client Application Programmed in Visual Basic. The 8bit DAC0832 chip is used as the Digital to Analog Converter. In this project open loop control of a DC motor will be established using a power amplifier, a digital to analog converter, 8255 digital interface card, a client PC and a Server PC.

The DAC circuit, which is controlled by the server computer via 8255 digital interface, will be used to control the speed of a DC motor by changing the voltage going to the base of the power amplifier. The voltage going into the motor from the power supply is between 0 and +5V. The role of the power amplifier circuit is to provide the current necessary, to operate the motor. The client computer, communicates with the server computer via Ethernet communications and it is the GUI interface to control the speed of the motor.

There can be several client computers hooked up to the server, however, for this application there is only one. The winsock component is used in the Visual Basic code to provide the server/client operations. This internet appliance calls for several electro-mechanical components: An 8255 card to interface the server PC with the dc motor control circuits.

The 8255 card`s purpose is to provide an interface between the server PC and the dc motor control circuits. More information on the 8255 card`s construction and operation may be found at. The DAC-LF353 op amp circuit provides the proper voltage to the TIP31, which regulates the current coming from the power supply.

The circuit is built so that it would output voltage ranging between 5V to +5V. The TIP31 circuit is a power amplifier, which allows current to flow from Collector through the Emitter pin proportional to the voltage on the Base pin. The illustration of the motor is given in Figure-2. The velocity command (RPM) is passed between from the client to the server using WinSock TCP/IP. The velocity command is then converted into a digital number and output to the DAC via Port A of the 8255 digital interface.

5. 5. Motor Current: Motor Current is monitored across the terminals of the motor used as a tachometer using a 100 Ohm resistor wired in series. Expensive and rare pieces of equipment may be brought closer to users all over the world. This allows those who cannot justify purchasing equipment to use it after an agreement is made with a host organization.

Organizations considering purchase of expensive equipment may be able to diffuse the cost of the equipment through renting time on the machine over the Internet. The customer base for this use is of course worldwide. In the considerably large facility, such as a power plant, there will be applications, which require controlling and monitoring on a constant basis.

In these plants there maybe networks, which is, consist of several server and client computers. One of the good examples of the using the server client architecture in a controls/monitoring environment is vibration-monitoring systems used in industrial plants. These consist of accelerometers attached to the critical components to determine the faults before they occur.

There are several data acquisition modules and server PCs acquiring data on a constant basis and taking the FFT and doing a trend analysis. The client computer retrieves this data and makes decisions like issuing alarms or shutting down the related part of the plant.

🔗 External reference

The schematic for this open loop speed control system integrates several key components that work together to achieve precise motor control. The 8255 Digital I/O Controller facilitates communication between the server and the motor control circuitry. It features multiple ports that allow for parallel data transfer, enabling real-time adjustments to motor speed based on user input from the client PC. The DAC0832 digital-to-analog converter translates digital commands from the 8255 into an analog voltage signal, which directly influences the base voltage of the TIP31 power amplifier.

The TIP31 functions as a current amplifier, controlling the motor’s power supply based on the voltage received. The operational amplifier (DAC-LF353) is crucial in maintaining stable voltage levels, ensuring that fluctuations do not affect motor performance. The power amplifier circuit is designed to handle the current requirements of the motor while providing a linear response to the input voltage.

For monitoring, a 100 Ohm resistor serves as a current sensing element, allowing for the measurement of motor current. This feedback loop is essential for maintaining the desired speed and for implementing safety features such as overload protection.

In terms of network architecture, the system leverages TCP/IP protocols to facilitate communication between the server and client PCs. The Winsock component in Visual Basic is instrumental in establishing this connection, allowing for seamless data transmission and control commands. This setup can be expanded with multiple clients, enhancing the system's scalability and flexibility in various industrial applications.

Overall, this circuit design exemplifies a robust approach to DC motor control, combining digital interfacing, analog signal processing, and networked communication to achieve efficient and effective motor management in a variety of operational settings.Open Loop Speed Control of a DC Motor via 8255 Digital I/O Controller chip using TCP/IP Server-Client Application Programmed in Visual Basic. The 8bit DAC0832 chip is used as the Digital to Analog Converter. In this project open loop control of a DC motor will be established using a power amplifier, a digital to analog converter, 8255 digital interface card, a client PC and a Server PC.

The DAC circuit, which is controlled by the server computer via 8255 digital interface, will be used to control the speed of a DC motor by changing the voltage going to the base of the power amplifier. The voltage going into the motor from the power supply is between 0 and +5V. The role of the power amplifier circuit is to provide the current necessary, to operate the motor. The client computer, communicates with the server computer via Ethernet communications and it is the GUI interface to control the speed of the motor.

There can be several client computers hooked up to the server, however, for this application there is only one. The winsock component is used in the Visual Basic code to provide the server/client operations. This internet appliance calls for several electro-mechanical components: An 8255 card to interface the server PC with the dc motor control circuits.

The 8255 card`s purpose is to provide an interface between the server PC and the dc motor control circuits. More information on the 8255 card`s construction and operation may be found at. The DAC-LF353 op amp circuit provides the proper voltage to the TIP31, which regulates the current coming from the power supply.

The circuit is built so that it would output voltage ranging between 5V to +5V. The TIP31 circuit is a power amplifier, which allows current to flow from Collector through the Emitter pin proportional to the voltage on the Base pin. The illustration of the motor is given in Figure-2. The velocity command (RPM) is passed between from the client to the server using WinSock TCP/IP. The velocity command is then converted into a digital number and output to the DAC via Port A of the 8255 digital interface.

5. 5. Motor Current: Motor Current is monitored across the terminals of the motor used as a tachometer using a 100 Ohm resistor wired in series. Expensive and rare pieces of equipment may be brought closer to users all over the world. This allows those who cannot justify purchasing equipment to use it after an agreement is made with a host organization.

Organizations considering purchase of expensive equipment may be able to diffuse the cost of the equipment through renting time on the machine over the Internet. The customer base for this use is of course worldwide. In the considerably large facility, such as a power plant, there will be applications, which require controlling and monitoring on a constant basis.

In these plants there maybe networks, which is, consist of several server and client computers. One of the good examples of the using the server client architecture in a controls/monitoring environment is vibration-monitoring systems used in industrial plants. These consist of accelerometers attached to the critical components to determine the faults before they occur.

There are several data acquisition modules and server PCs acquiring data on a constant basis and taking the FFT and doing a trend analysis. The client computer retrieves this data and makes decisions like issuing alarms or shutting down the related part of the plant.

🔗 External reference