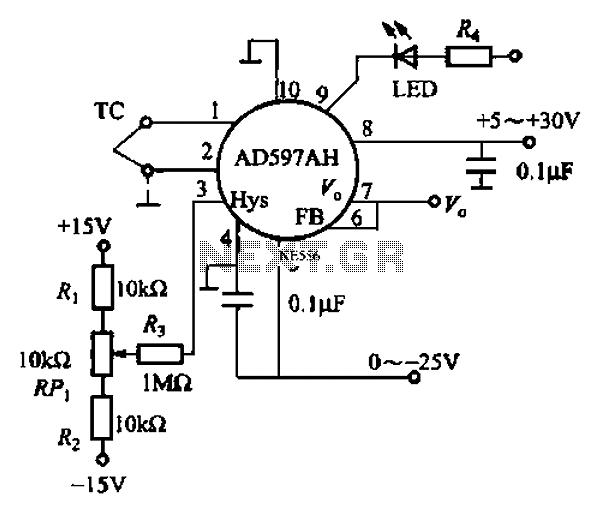

Positive Voltage Reference Circuit

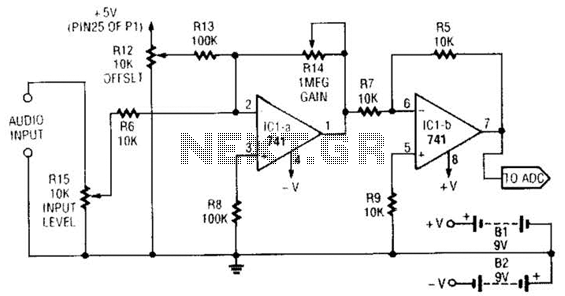

The circuit is designed for high precision operation over an extended temperature range, provided that V+ remains relatively constant, as the current IZ is dependent on V+. Resistors R1, R2, R3, and R4 are selected to ensure the appropriate IZ for minimal temperature coefficient and to reduce errors caused by bias current (Ibias). The circuits depicted should be compensated for unity gain operation or, if large capacitive loads are anticipated, overcompensated. Output noise can be minimized in both circuits by bypassing the amplifier input. The schematic illustrates that the circuits utilize a single power supply, necessitating careful consideration of the common mode range when selecting an amplifier for these applications. If the common mode range requirements exceed the amplifier's capabilities, a dual power supply configuration may be employed. The LH101 amplifier can operate with a single power supply, as its common mode range extends from V+ to approximately 2 volts above V-.

The described circuit is engineered to maintain high precision and stability across a wide temperature spectrum, which is particularly important in environments where temperature fluctuations can affect performance. The dependency of IZ on V+ highlights the importance of a stable power supply to ensure consistent operation. The selection of resistors R1 through R4 is critical; these components are carefully chosen to optimize the current IZ, thereby minimizing the temperature coefficient. This ensures that variations in temperature do not significantly affect the circuit's output.

The compensation for unity gain operation is essential for maintaining stability, particularly in feedback configurations. In scenarios where large capacitive loads are expected, overcompensation is advised to prevent oscillations and ensure reliable performance. Bypassing the amplifier input is a technique employed to further reduce output noise, which can be particularly beneficial in sensitive applications where signal integrity is paramount.

The use of a single power supply simplifies the circuit design but introduces challenges related to the common mode range of the amplifier. It is crucial to select an amplifier that can handle the expected common mode voltages without distortion or loss of performance. In cases where the amplifier's common mode range is insufficient, implementing a dual power supply can provide the necessary headroom to accommodate the input signal range.

The LH101 amplifier is noted for its capability to operate effectively within the specified power supply configuration, making it a suitable choice for this circuit. Its common mode range, extending from V+ down to approximately 2 volts above V-, allows for flexibility in design while ensuring that the amplifier can handle the input signals without compromising performance. Overall, careful consideration of component selection and configuration is essential to achieve the desired precision and reliability in this circuit design.The circuit are suited for high precision extended temperature service if V+ is reasonably constant since IZ is dependent on V+. R1, R2, R3, and R4 are chosen to provide the proper IZ for minimum T. C. and to minimize errors due to Ibias. The circuits shown should both be compensated for unity gain operation or, if large capacitive loads are expect

ed, should be overcompensated. Output noise may be reduced in both circuits by bypassing the amplifier input. Here is a schematic drawing: The circuits shown employ a single power supply, this requires that common mode range be considered in choosing an amplifier for these applications. If the common mode range requirements are in excess of the capability of the amplifier, two power supplies may be used.

The LH101 may be used with a single power supply since the common mode range is from V+ to within approximately 2 volts of V-. 🔗 External reference

The described circuit is engineered to maintain high precision and stability across a wide temperature spectrum, which is particularly important in environments where temperature fluctuations can affect performance. The dependency of IZ on V+ highlights the importance of a stable power supply to ensure consistent operation. The selection of resistors R1 through R4 is critical; these components are carefully chosen to optimize the current IZ, thereby minimizing the temperature coefficient. This ensures that variations in temperature do not significantly affect the circuit's output.

The compensation for unity gain operation is essential for maintaining stability, particularly in feedback configurations. In scenarios where large capacitive loads are expected, overcompensation is advised to prevent oscillations and ensure reliable performance. Bypassing the amplifier input is a technique employed to further reduce output noise, which can be particularly beneficial in sensitive applications where signal integrity is paramount.

The use of a single power supply simplifies the circuit design but introduces challenges related to the common mode range of the amplifier. It is crucial to select an amplifier that can handle the expected common mode voltages without distortion or loss of performance. In cases where the amplifier's common mode range is insufficient, implementing a dual power supply can provide the necessary headroom to accommodate the input signal range.

The LH101 amplifier is noted for its capability to operate effectively within the specified power supply configuration, making it a suitable choice for this circuit. Its common mode range, extending from V+ down to approximately 2 volts above V-, allows for flexibility in design while ensuring that the amplifier can handle the input signals without compromising performance. Overall, careful consideration of component selection and configuration is essential to achieve the desired precision and reliability in this circuit design.The circuit are suited for high precision extended temperature service if V+ is reasonably constant since IZ is dependent on V+. R1, R2, R3, and R4 are chosen to provide the proper IZ for minimum T. C. and to minimize errors due to Ibias. The circuits shown should both be compensated for unity gain operation or, if large capacitive loads are expect

ed, should be overcompensated. Output noise may be reduced in both circuits by bypassing the amplifier input. Here is a schematic drawing: The circuits shown employ a single power supply, this requires that common mode range be considered in choosing an amplifier for these applications. If the common mode range requirements are in excess of the capability of the amplifier, two power supplies may be used.

The LH101 may be used with a single power supply since the common mode range is from V+ to within approximately 2 volts of V-. 🔗 External reference