power electronic design

This document discusses the power electronics required for an electrical discharge machining (EDM) machine. The fundamental mechanism of EDM involves a controlled spark between the electrode and the workpiece. The electronic design must generate the necessary waveforms to induce this spark. The discussion begins with the basic principles of EDM, including the voltage, current, and frequency requirements, followed by a simple circuit that meets these needs. Limitations of this circuit will be addressed with an improved design. Breakdown voltage measurements indicate that while 60V is insufficient, 150V is also inadequate for electrode spacings of 0.001 to 0.010 inches. Previous work by Doret introduced a 1500V "tickler" pulse to reliably trigger breakdown at these spacings. Commercial machines, such as those from Elox, utilize an 85V-90V peak-to-peak square wave to drive the electrode. A table provided by Doret illustrates the relationship between breakdown voltage and the voltage for Eloxol #13 dielectric, suggesting that the voltage across the gap after breakdown is typically 10V-15V, regardless of current. The resistance of the gap is usually around 1 ohm. The arc voltage remains relatively constant as the arc current varies. A short circuit between the electrode and workpiece is indicated by a voltage drop to nearly zero and a sharp increase in current. Most servo mechanisms rely on feedback from the average current through or voltage across the electrodes, indirectly sensing the proportion of open or shorted pulses and adjusting the electrode distance accordingly. An open circuit results in high voltage and low current, while a short circuit leads to low voltage and high current. Juvkam-Wold describes a head servo that maintains spacing to ensure breakdown occurs at a preset voltage. Effective pulse widths can range from 13μs to 100μs, with little benefit from pulses exceeding 100μs. The optimal method for material removal, particularly from a copper anode using a graphite cathode, involves high current pulses of short duration at high frequency. The design aims to generate 100μs pulses of 50A at either 150V or 300V peak-to-peak, which should suffice for operation at gaps of up to 0.002" (for 150V) or 0.004" (for 300V). The machine will be powered by a standard 15A Edison circuit, necessitating a duty cycle of approximately 33% to maintain an average current draw of 15A. The power delivered to the electrodes is constrained by the transformer capacity, with the input voltage (60V) being somewhat low for EDM applications. Eliminating the transformer increases the voltage to approximately 150V, allowing for maximum current draw from a standard wall outlet (15A). However, this passive approach results in significant power dissipation in the current-limiting resistors, necessitating 1700W in R1 and about 2000W in the electrode current limiting resistor, which can be prohibitively expensive. Instead of passive current limiting, an active circuit design is proposed. This circuit monitors the current flowing through the system, switching off the source if the current exceeds a predetermined limit, and restoring power when the current falls back within acceptable levels. While this on-and-off action may introduce some ripple in the output current, maintaining a sufficiently high frequency should keep the ripple within reasonable limits. Instead of a series current-limiting resistor, a small sense resistor is implemented to measure current flow. An inductor is added to limit the rate of current change, ensuring the switches can respond quickly to sudden increases in current. Feedback mechanisms are integrated to monitor whether sparking occurs correctly or if there is an open or short condition, which is essential for maintaining the electrode gap distance. The circuit incorporates LEDs as inputs to optoisolators, with diodes functioning as makeshift voltage regulators. Additionally, a method to sense capacitor voltage for low-voltage pulses is included. The full schematic elaborates on these concepts, with IGBT power transistors requiring a specialized gate drive circuit (IR2108), potentially necessitating a charge pump (ICM7555) for sustained gate drive voltage. All power electronics are optoisolated from control electronics, with a separate 15V supply for the switching regulator control. The schematic has been updated to enhance current regulation through the electrode gap, including a catch diode to maintain current flow through the gap when the voltage source is switched off. An additional "boost" transistor is incorporated; when activated, it allows for an initial current flow through the output inductor, which can then be switched off to create the necessary voltage across the gap. A zener diode (MOSORB) protects the boost transistor from excessive voltage. Further updates have added a second gate driver chip (IR2117) to accommodate these modifications, and the schematic now includes a Vsense input to the comparators for improved functionality.

The EDM machine design involves a complex interplay of electronic components to achieve precise control over the machining process. The circuit is centered around generating high-frequency pulses capable of inducing electrical discharge between the electrode and the workpiece. The choice of components, including IGBT transistors, optoisolators, and feedback mechanisms, ensures reliable operation while managing power dissipation effectively. The implementation of active current limiting through feedback control not only enhances efficiency but also protects sensitive components from damage due to excessive current. The integration of sensing capabilities for both current and voltage allows for adaptive operation, ensuring that the machining process remains stable under varying conditions. The design prioritizes safety and reliability, making it suitable for practical applications in precision machining.On this page we will discuss the power electronics needed for our EDM machine. The basic mechanism of electrical discharge machining is a controlled spark between the electrode and the workpiece. This part of the electronic design generates the waveforms necessary to induce the spark. We will start by describing the fundamental mechanisms of EDM w hich dictate the voltage, current, and frequency needed, then show a very simple circuit satifying these requirements before describing its limitations and addressing these with an improved circuit. I spent some time in the library reading all the material on EDM that I could find. I will attempt to give a bibliographical reference for each essential fact I note below, to allow the curious reader to duplicate my research.

Breakdown voltage from 60V [LAN], but 150V is inadequate to cause dielectric breakdown at. 001 -. 010 inch electrode spacings [DOR]. Doret added a 1500V "tickler" (low current, short duration) to trigger breakdown reliably up to. 010 inch. But he reports that the commerical machine made by Elox uses a 85V-90V peak-to-peak square wave to drive its electrode. Doret provided the following table of breakdown voltage versus voltage for Eloxol #13 dielectric (results not exactly reproducible, but are illustrative): Voltage across gap after breakdown is 10V-15V typical, independent of current.

Gap resistance is usually around 1 ohm. "Arc voltage remains relatively constant as arc current is varied. " Short circuit between electrode and workpiece is indicated by voltage dropping to almost zero and current increasing sharply [DOR]. Most servo mechanisms use feedback based on average current through or voltage gap across the electrodes.

But these mechanisms are just indirectly sensing the number (proportion) of open or shorted pulses, and adjusting the electrode distance to minimize these [LIV]. An open circuit causes voltage to stay high and current to decrease; a short circuit causes voltage to drop to zero and current to increase.

Juvkam-Wold describes a head servo which tries to maintain spacing such that breakdown will occur at some preset voltage [JUV]. Effective pulse width can range from 13us to 100us. Little benefit is realized by applying pulses of over 100us. The fastest way to remove material (from a copper anode using a graphite cathode) is to use high current pulses of short duration at high frequency [DOR].

We will design our EDM to generate 100us pulses of 50A at either 150V or 300V peak-to-peak. This should be sufficient for operation at gaps up to. 002" (for 150V) or. 004" (for 300V). We will be driving the machine from a standard 15A edison circuit (the kind you have in your home), so our ideal duty cycle will be around 33% to keep the average current draw down to 15A. The power delivered to the electrodes is limited by the capacity of the transformer at the input, and the voltage (60V) is a little low by EDM standards.

Omitting the transformer increases voltage to about 150V and allows us to suck up as much current as a standard wall outlet will give (15A): The main drawback with a circuit of this type is the large amount of power dissipated in the current-limiting resistors (R1 in the above; both circuits as drawn are also missing additional current-limiting resistors in series with the electrode). Current-limiting is necessary to protect the switching transistors and other components, which can only handle a limited amount of current.

But the passive approach requires 1700W to be dissipated in R1 and about 2000kW to be dissipated in the electrode current limiting resistor. Resistors that can handle this amount of power are expensive - DigiKey lists 1000W resistors for over $100 each, and we`d need 4 of them!

Instead of passively limiting our current, we can use an active circuit to do so. The basic idea is that we will watch the current flowing through the circuit, and if it ever exceeds our desired limit value, we will flip a switch and turn the source off. When the current falls back down to an acceptable value, we`ll turn the source back on. The on-and-off action will generate a little bit of ripple in the output current, but if we keep the frequency high enough the ripple should be reasonable.

Instead of a series current-limiting resistor, we have only a very small "sense" resistor: the voltage across the sense resistor will tell us how much current is flowing through the loop. We add an inductor, L, to limit the rate of change of the current, to ensure that our switches are fast enough to restrict sudden rises in current.

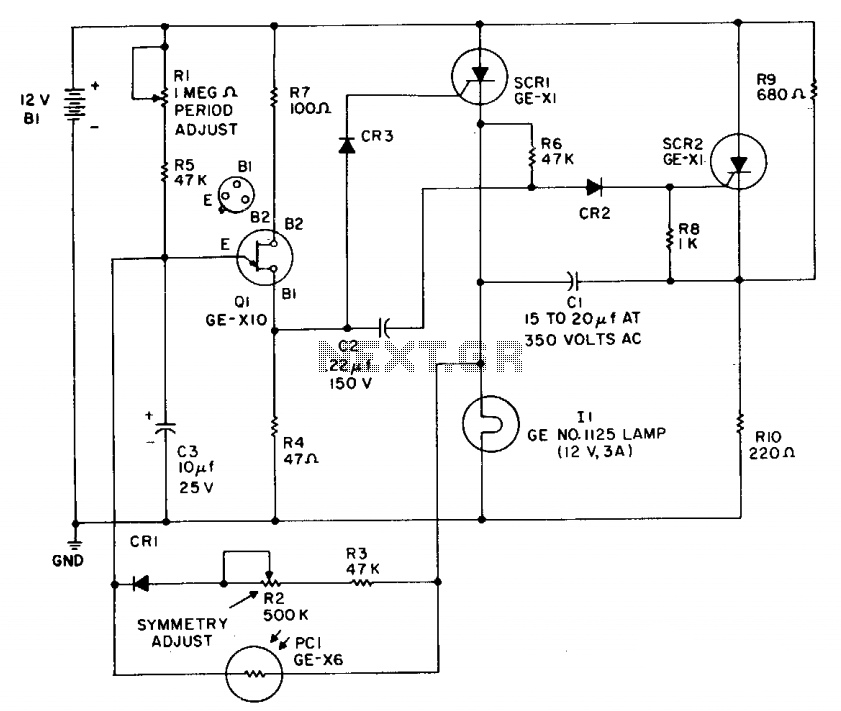

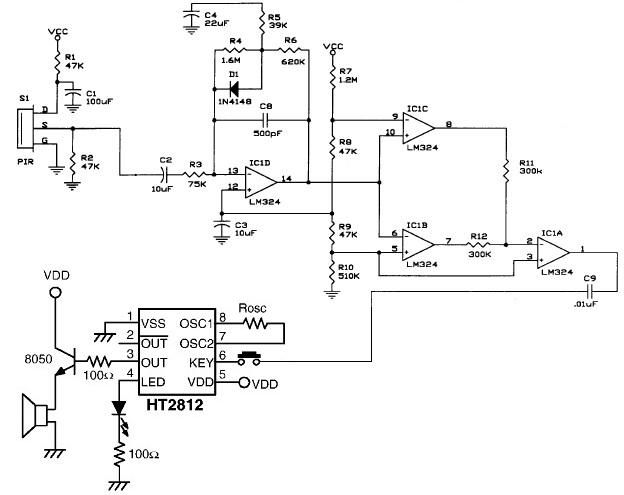

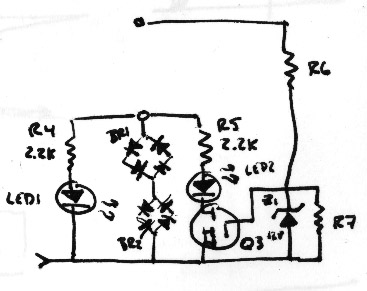

We need some feedback on whether we`re sparking correctly or have an open or short condition in order to maintain the electrode gap distance properly. The following circuit provides this. The LEDs in the circuit are inputs to optoisolators. Note the use of diodes as impromptu voltage regulators. We`d also like to be able to sense the current capacitor voltage to allow low-voltage pulses. This circuit does that. Again, the LED is input to an analog-input optoisolator; the op-amp circuit maintains the current through the LED to be proportional to the voltage drop across the capacitor.

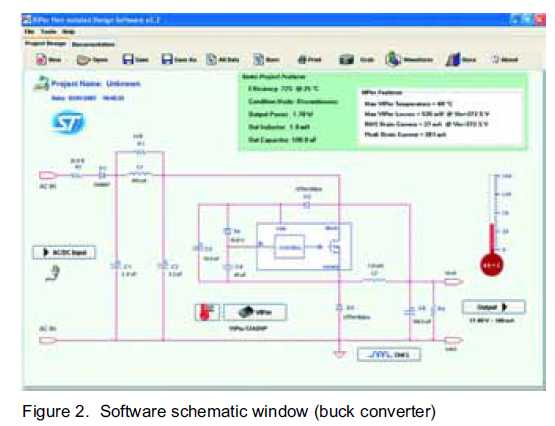

The full schematic fleshes out the rough sketches above. The IGBT power transistors require a special gate drive circuit, the IR2108; in this application we might need a charge pump (the ICM7555) to obtain a sustained gate drive voltage. All the power electronics are optoisolated from the control electronics. We`ve got a separate 15V supply to run the switching regulator control. Updated! I`ve updated the schematic above to better regulate the current through the electrode gap. We need a catch diode to continue directing current (from the inductor) through the gap even when the voltage source (the power capacitor) is switched off.

I also added an extra "boost" transistor to the circuit. If we initially turn this on, we`ll get 50A or so of current flowing through the output inductor, although there will be no voltage across the gap. Switching the boost transistor off will cause the current to flow across the gap - and the inductor will raise the voltage at the electrode to whatever level is necessary to make this happen.

We potentially get quite a lot of voltage boost here, ensuring a good spark. The zener diode (MOSORB) across the boost transistor ensures that the voltage doesn`t get high enough to toast the transistor. We needed to add another gate driver chip (the IR2117) to accomodate these changes. Updated! (again) I`ve updated the schematic to reflect my most recent working version; in particular the old version was missing the Vsense input to the comparators (oops).

I`ve also posted an email I recently wrote to Roger Cook, giving some more details on component specification and circuit operation. 🔗 External reference

The EDM machine design involves a complex interplay of electronic components to achieve precise control over the machining process. The circuit is centered around generating high-frequency pulses capable of inducing electrical discharge between the electrode and the workpiece. The choice of components, including IGBT transistors, optoisolators, and feedback mechanisms, ensures reliable operation while managing power dissipation effectively. The implementation of active current limiting through feedback control not only enhances efficiency but also protects sensitive components from damage due to excessive current. The integration of sensing capabilities for both current and voltage allows for adaptive operation, ensuring that the machining process remains stable under varying conditions. The design prioritizes safety and reliability, making it suitable for practical applications in precision machining.On this page we will discuss the power electronics needed for our EDM machine. The basic mechanism of electrical discharge machining is a controlled spark between the electrode and the workpiece. This part of the electronic design generates the waveforms necessary to induce the spark. We will start by describing the fundamental mechanisms of EDM w hich dictate the voltage, current, and frequency needed, then show a very simple circuit satifying these requirements before describing its limitations and addressing these with an improved circuit. I spent some time in the library reading all the material on EDM that I could find. I will attempt to give a bibliographical reference for each essential fact I note below, to allow the curious reader to duplicate my research.

Breakdown voltage from 60V [LAN], but 150V is inadequate to cause dielectric breakdown at. 001 -. 010 inch electrode spacings [DOR]. Doret added a 1500V "tickler" (low current, short duration) to trigger breakdown reliably up to. 010 inch. But he reports that the commerical machine made by Elox uses a 85V-90V peak-to-peak square wave to drive its electrode. Doret provided the following table of breakdown voltage versus voltage for Eloxol #13 dielectric (results not exactly reproducible, but are illustrative): Voltage across gap after breakdown is 10V-15V typical, independent of current.

Gap resistance is usually around 1 ohm. "Arc voltage remains relatively constant as arc current is varied. " Short circuit between electrode and workpiece is indicated by voltage dropping to almost zero and current increasing sharply [DOR]. Most servo mechanisms use feedback based on average current through or voltage gap across the electrodes.

But these mechanisms are just indirectly sensing the number (proportion) of open or shorted pulses, and adjusting the electrode distance to minimize these [LIV]. An open circuit causes voltage to stay high and current to decrease; a short circuit causes voltage to drop to zero and current to increase.

Juvkam-Wold describes a head servo which tries to maintain spacing such that breakdown will occur at some preset voltage [JUV]. Effective pulse width can range from 13us to 100us. Little benefit is realized by applying pulses of over 100us. The fastest way to remove material (from a copper anode using a graphite cathode) is to use high current pulses of short duration at high frequency [DOR].

We will design our EDM to generate 100us pulses of 50A at either 150V or 300V peak-to-peak. This should be sufficient for operation at gaps up to. 002" (for 150V) or. 004" (for 300V). We will be driving the machine from a standard 15A edison circuit (the kind you have in your home), so our ideal duty cycle will be around 33% to keep the average current draw down to 15A. The power delivered to the electrodes is limited by the capacity of the transformer at the input, and the voltage (60V) is a little low by EDM standards.

Omitting the transformer increases voltage to about 150V and allows us to suck up as much current as a standard wall outlet will give (15A): The main drawback with a circuit of this type is the large amount of power dissipated in the current-limiting resistors (R1 in the above; both circuits as drawn are also missing additional current-limiting resistors in series with the electrode). Current-limiting is necessary to protect the switching transistors and other components, which can only handle a limited amount of current.

But the passive approach requires 1700W to be dissipated in R1 and about 2000kW to be dissipated in the electrode current limiting resistor. Resistors that can handle this amount of power are expensive - DigiKey lists 1000W resistors for over $100 each, and we`d need 4 of them!

Instead of passively limiting our current, we can use an active circuit to do so. The basic idea is that we will watch the current flowing through the circuit, and if it ever exceeds our desired limit value, we will flip a switch and turn the source off. When the current falls back down to an acceptable value, we`ll turn the source back on. The on-and-off action will generate a little bit of ripple in the output current, but if we keep the frequency high enough the ripple should be reasonable.

Instead of a series current-limiting resistor, we have only a very small "sense" resistor: the voltage across the sense resistor will tell us how much current is flowing through the loop. We add an inductor, L, to limit the rate of change of the current, to ensure that our switches are fast enough to restrict sudden rises in current.

We need some feedback on whether we`re sparking correctly or have an open or short condition in order to maintain the electrode gap distance properly. The following circuit provides this. The LEDs in the circuit are inputs to optoisolators. Note the use of diodes as impromptu voltage regulators. We`d also like to be able to sense the current capacitor voltage to allow low-voltage pulses. This circuit does that. Again, the LED is input to an analog-input optoisolator; the op-amp circuit maintains the current through the LED to be proportional to the voltage drop across the capacitor.

The full schematic fleshes out the rough sketches above. The IGBT power transistors require a special gate drive circuit, the IR2108; in this application we might need a charge pump (the ICM7555) to obtain a sustained gate drive voltage. All the power electronics are optoisolated from the control electronics. We`ve got a separate 15V supply to run the switching regulator control. Updated! I`ve updated the schematic above to better regulate the current through the electrode gap. We need a catch diode to continue directing current (from the inductor) through the gap even when the voltage source (the power capacitor) is switched off.

I also added an extra "boost" transistor to the circuit. If we initially turn this on, we`ll get 50A or so of current flowing through the output inductor, although there will be no voltage across the gap. Switching the boost transistor off will cause the current to flow across the gap - and the inductor will raise the voltage at the electrode to whatever level is necessary to make this happen.

We potentially get quite a lot of voltage boost here, ensuring a good spark. The zener diode (MOSORB) across the boost transistor ensures that the voltage doesn`t get high enough to toast the transistor. We needed to add another gate driver chip (the IR2117) to accomodate these changes. Updated! (again) I`ve updated the schematic to reflect my most recent working version; in particular the old version was missing the Vsense input to the comparators (oops).

I`ve also posted an email I recently wrote to Roger Cook, giving some more details on component specification and circuit operation. 🔗 External reference