preamp circuit 3

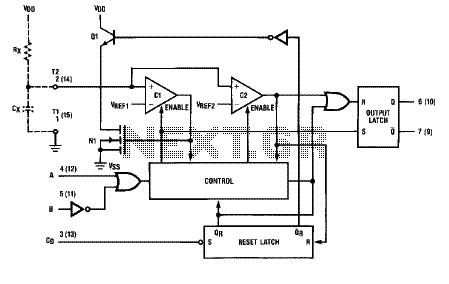

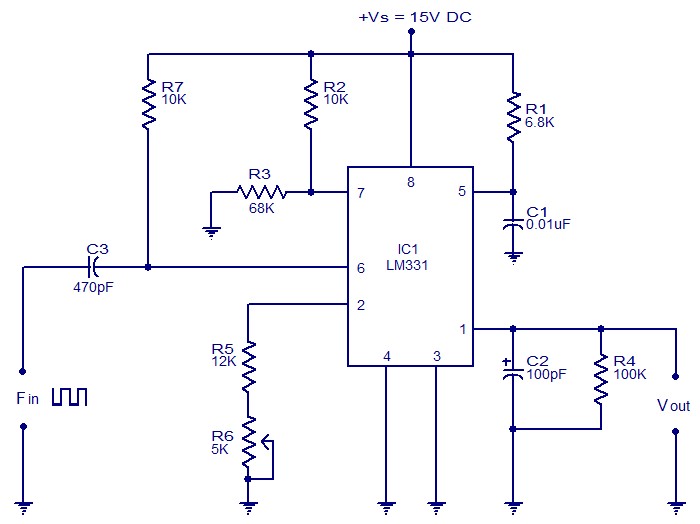

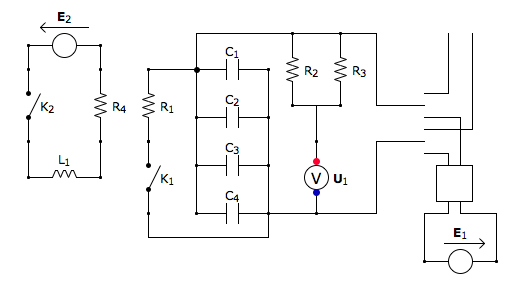

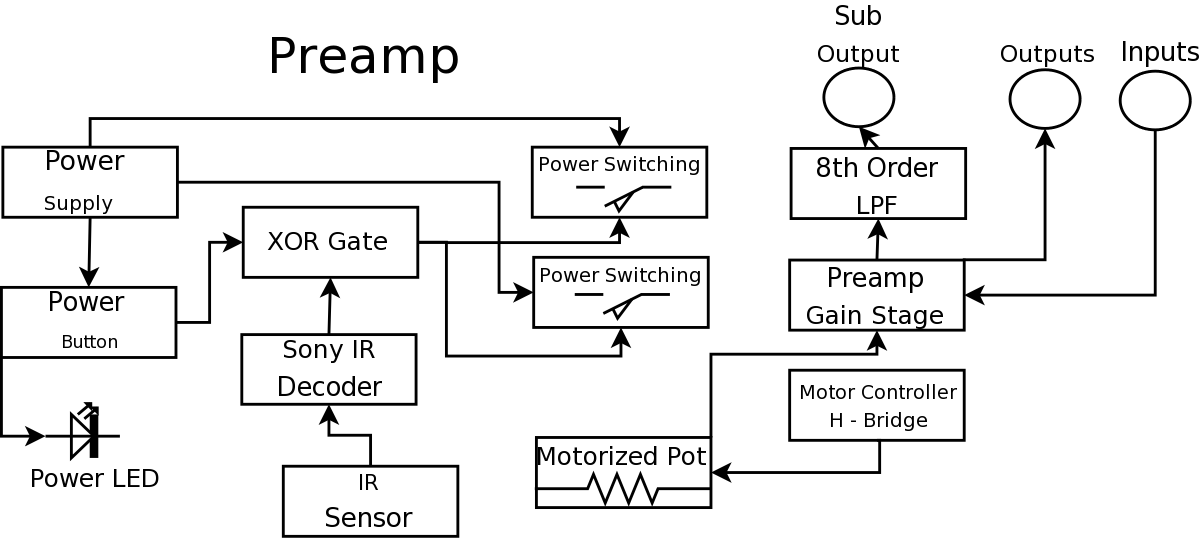

During a Digital Projects Lab, the professor suggested incorporating more circuit-level work into a project. To achieve this, a preamplifier was designed, which included an infrared (IR) remote control to replace a previously built version. The earlier preamplifier functioned well but lacked aesthetic appeal and was constructed on a breadboard rather than a printed circuit board (PCB). The entire preamplifier circuitry was designed from scratch. The PCB was fabricated using a laser printer and toner transfer paper. The image shows the volume and power control circuit just before printing on the Press 'n Peel Blue toner transfer paper. The yellow text serves as labeling. The bottom 18-pin dual in-line package (DIP) chip is a microcontroller that decodes Sony IR signals, the 14-pin DIP chip is an XOR gate, the two large rectangles represent relays, and the smaller rectangles are voltage regulators. The text appears reversed due to being the first circuit board created. An additional image shows the 8th order low-pass filter (LPF) with a cutoff frequency (Fc) of 90 Hz, depicting the PCB printout at the final stage, ready for printing on the toner transfer paper. The power supply is located on the far left, with the power control circuitry beneath it and the 8th order low-pass filter above. Further to the right is the motor control circuit at the bottom and the preamplifier at the top.

The described preamplifier circuit integrates various components to enhance functionality and performance. The microcontroller serves as the central processing unit, decoding signals from an IR remote, allowing for wireless control of the preamplifier's operations. The use of an XOR gate enables specific logic functions necessary for signal processing within the circuit. The relays act as switches, controlling the power to different sections of the circuit based on the microcontroller's commands, while the voltage regulators ensure stable power supply levels to sensitive components.

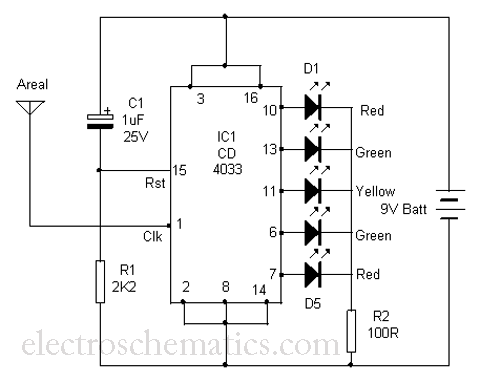

The 8th order low-pass filter (LPF) is crucial for eliminating high-frequency noise from the audio signals, ensuring that only frequencies below 90 Hz pass through to the output. This filter design employs multiple stages to achieve a steeper roll-off, improving audio clarity and fidelity. The layout of the PCB is significant, as it minimizes signal interference and optimizes the routing of power and ground connections, which is essential for maintaining signal integrity in audio applications.

The choice of using toner transfer paper for PCB fabrication indicates a hands-on approach to learning and experimentation, allowing for customization of the circuit design while providing practical experience in PCB manufacturing techniques. The final assembly, including the power supply and motor control circuits, showcases a well-thought-out integration of multiple functionalities within a single preamplifier unit, reflecting a comprehensive understanding of electronic design principles.During my Digital Projects Lab, the professor recommended I find a way to include more circuit level work into my project. To fulfill this, I decided to build a nice preamplifier which wouldinclude an IR remote control to replace the one I had built previous.

The previous preamp I had made worked well but it was not aesthetics pleasing and was bui lt on breadboard rather than a PCB board. The entire preamplifier circuitry was designed from the ground up by myself. The PCB boards were also created by myself using a laser printer and Toner Transfer Paper. This picture shows the volume and power controlling circuit as it appears just before printing it out on the Press `n Peel Blue toner transfer paper. The yellow text provides labeling. The bottom 18 pin dip chip is the micro controller which decodes Sony IR signals, the 14 pin dip chip is an xor gate the two large rectangles are relays, and the smaller rectangles are voltage regulators.

Yes, I understand the text is printed backwards. It was my first circuit board. This picture is of the 8th order LPF with an Fc of 90Hz. It shows what the PCB printout looks at the final stage. This is what is sent to the laser printer to be printed on the toner transfer paper. On the far left is the power supply. To the right of that is the power controlling circuitry on the bottom and the 8th order low pass filter on the top. Further right is the motor controlling circuit on the bottom and the preamplifier on the top. 🔗 External reference

The described preamplifier circuit integrates various components to enhance functionality and performance. The microcontroller serves as the central processing unit, decoding signals from an IR remote, allowing for wireless control of the preamplifier's operations. The use of an XOR gate enables specific logic functions necessary for signal processing within the circuit. The relays act as switches, controlling the power to different sections of the circuit based on the microcontroller's commands, while the voltage regulators ensure stable power supply levels to sensitive components.

The 8th order low-pass filter (LPF) is crucial for eliminating high-frequency noise from the audio signals, ensuring that only frequencies below 90 Hz pass through to the output. This filter design employs multiple stages to achieve a steeper roll-off, improving audio clarity and fidelity. The layout of the PCB is significant, as it minimizes signal interference and optimizes the routing of power and ground connections, which is essential for maintaining signal integrity in audio applications.

The choice of using toner transfer paper for PCB fabrication indicates a hands-on approach to learning and experimentation, allowing for customization of the circuit design while providing practical experience in PCB manufacturing techniques. The final assembly, including the power supply and motor control circuits, showcases a well-thought-out integration of multiple functionalities within a single preamplifier unit, reflecting a comprehensive understanding of electronic design principles.During my Digital Projects Lab, the professor recommended I find a way to include more circuit level work into my project. To fulfill this, I decided to build a nice preamplifier which wouldinclude an IR remote control to replace the one I had built previous.

The previous preamp I had made worked well but it was not aesthetics pleasing and was bui lt on breadboard rather than a PCB board. The entire preamplifier circuitry was designed from the ground up by myself. The PCB boards were also created by myself using a laser printer and Toner Transfer Paper. This picture shows the volume and power controlling circuit as it appears just before printing it out on the Press `n Peel Blue toner transfer paper. The yellow text provides labeling. The bottom 18 pin dip chip is the micro controller which decodes Sony IR signals, the 14 pin dip chip is an xor gate the two large rectangles are relays, and the smaller rectangles are voltage regulators.

Yes, I understand the text is printed backwards. It was my first circuit board. This picture is of the 8th order LPF with an Fc of 90Hz. It shows what the PCB printout looks at the final stage. This is what is sent to the laser printer to be printed on the toner transfer paper. On the far left is the power supply. To the right of that is the power controlling circuitry on the bottom and the 8th order low pass filter on the top. Further right is the motor controlling circuit on the bottom and the preamplifier on the top. 🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713