pressure sensor circuit

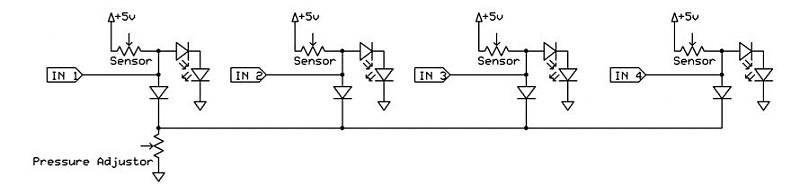

A dance pad consists of four pressure sensors (up, down, left, right). A USB controller has already been created for the dance pad, and the next step involves connecting the actual sensors. The intention is to pull the input down to ground using a rheostat as a variable resistor for the pulldown. This setup would allow for the adjustment of the pressure required from the sensors. If the resistance in the sensor is lower, it should register a button press, while a lower resistance through the pulldown should register a zero. The goal is to use a single pulldown adjustor for all sensors to avoid the need for individual rheostats for each sensor. A schematic was initially proposed, but pressing a sensor resulted in all inputs going high. The issue identified is that the schematic was drawn incorrectly, as the outputs from the variable resistors should come off the wiper rather than the opposite side. Additionally, an analog-to-digital converter cannot be used since there will be at least two pads, each with its own pressure sensor. The current design allows the outputs from the sensors to either connect to USB or another pad that sends the data to USB, requiring only simple binary outputs. The adjustor pot was previously connected to the 5-volt source to adjust the voltage, but this approach was not satisfactory and may require further experimentation.

The design of the dance pad involves utilizing four pressure sensors arranged in a manner that corresponds to directional inputs: up, down, left, and right. Each sensor operates by detecting pressure applied to it, which changes its resistance. The goal is to create a system where a single variable resistor, or rheostat, serves as a pulldown for all four sensors. This allows for the adjustment of the sensitivity threshold, enabling the user to customize how much pressure is needed to register a button press.

In the intended design, when pressure is applied to a sensor, its resistance decreases, causing the corresponding input to register a high signal. Conversely, if the resistance is increased, the input should read low. The use of a common pulldown resistor simplifies the circuit and reduces component count, which is beneficial for both space and cost efficiency.

The schematic should reflect that each pressure sensor's output connects to the wiper terminal of the rheostat. This configuration allows for the voltage to be adjusted based on the pressure applied to the sensors. It is crucial to ensure that the correct wiring is followed to prevent all inputs from going high when one sensor is activated.

To achieve a reliable output, the circuit can be designed with pull-up resistors connected to the microcontroller's input pins. This configuration ensures that when no pressure is applied, the inputs are held high, and when a sensor is activated, the input is pulled low through the rheostat. The output from the sensors can be fed directly into a USB interface, allowing for straightforward integration with a computer or gaming system.

It is important to note that the system must be able to handle multiple simultaneous inputs, especially if multiple sensors are pressed at once. This may require additional circuitry or a more sophisticated microcontroller that can manage multiple digital inputs effectively.

In summary, a properly configured dance pad circuit will involve pressure sensors, a common pulldown rheostat, and a microcontroller capable of interpreting the binary outputs from the sensors. Careful attention to the schematic design and component selection will ensure the functionality and responsiveness of the dance pad.A dance pad, basically 4 pressure sensors (up, down, left, right). I already made the USB controller as a dance pad and whatnot, now I need to know how to hook up the actual sensors. I want the input to be pulled down to ground, so I figured that I would put a rheostat there as a variable resistor for the pulldown.

This way, I could adjust how strong the pull-down is, theoretically adjusting the amount of pressure required from the sensors. If the resistance is less in the sensor, then it should register a button press, whereas if the resistance is less through the pulldown, it should register a 0. That part all works just great, however, I want all of the sensors to use one pulldown adjustor, so I dont need to put 1 rheostat per sensor.

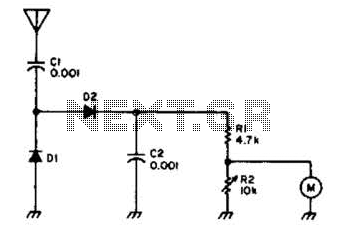

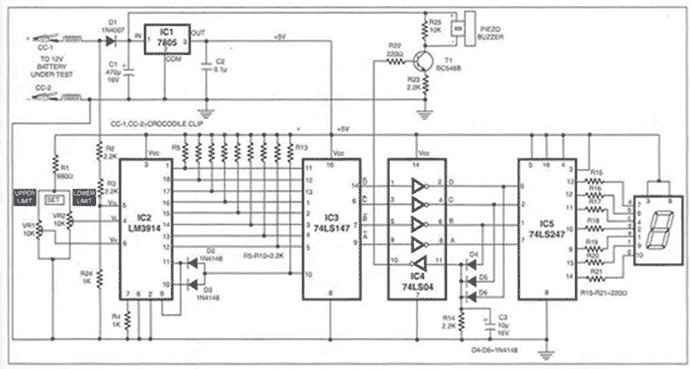

Attached is a schematic I thought would work, but in fact when I press a sensor, all of the inputs go high. What am I doing wrong EDIT: The schematic is drawn wrong. For all of those variable resistors, the outputs actually come off of the wiper, not the other side. I couldn`t find out how to do this in the schematic program, so I drew it like such to show the general idea.

All the resistors in the image are variable and set-up to be such. Actually, I cant use the AD converter beacuse there will be two pads at least and each should have its own pressure sensor. The way I did it, the outputs from the sensors can either go into USB, or can go out to another pad, which sends it to USB, so I need just simple 1 or 0`s I think I tried putting the adjustor pot on the 5volt source, adjusting the voltage.

Didnt really like how it worked, but maybe Ill mess around with that again, thanks. 🔗 External reference

The design of the dance pad involves utilizing four pressure sensors arranged in a manner that corresponds to directional inputs: up, down, left, and right. Each sensor operates by detecting pressure applied to it, which changes its resistance. The goal is to create a system where a single variable resistor, or rheostat, serves as a pulldown for all four sensors. This allows for the adjustment of the sensitivity threshold, enabling the user to customize how much pressure is needed to register a button press.

In the intended design, when pressure is applied to a sensor, its resistance decreases, causing the corresponding input to register a high signal. Conversely, if the resistance is increased, the input should read low. The use of a common pulldown resistor simplifies the circuit and reduces component count, which is beneficial for both space and cost efficiency.

The schematic should reflect that each pressure sensor's output connects to the wiper terminal of the rheostat. This configuration allows for the voltage to be adjusted based on the pressure applied to the sensors. It is crucial to ensure that the correct wiring is followed to prevent all inputs from going high when one sensor is activated.

To achieve a reliable output, the circuit can be designed with pull-up resistors connected to the microcontroller's input pins. This configuration ensures that when no pressure is applied, the inputs are held high, and when a sensor is activated, the input is pulled low through the rheostat. The output from the sensors can be fed directly into a USB interface, allowing for straightforward integration with a computer or gaming system.

It is important to note that the system must be able to handle multiple simultaneous inputs, especially if multiple sensors are pressed at once. This may require additional circuitry or a more sophisticated microcontroller that can manage multiple digital inputs effectively.

In summary, a properly configured dance pad circuit will involve pressure sensors, a common pulldown rheostat, and a microcontroller capable of interpreting the binary outputs from the sensors. Careful attention to the schematic design and component selection will ensure the functionality and responsiveness of the dance pad.A dance pad, basically 4 pressure sensors (up, down, left, right). I already made the USB controller as a dance pad and whatnot, now I need to know how to hook up the actual sensors. I want the input to be pulled down to ground, so I figured that I would put a rheostat there as a variable resistor for the pulldown.

This way, I could adjust how strong the pull-down is, theoretically adjusting the amount of pressure required from the sensors. If the resistance is less in the sensor, then it should register a button press, whereas if the resistance is less through the pulldown, it should register a 0. That part all works just great, however, I want all of the sensors to use one pulldown adjustor, so I dont need to put 1 rheostat per sensor.

Attached is a schematic I thought would work, but in fact when I press a sensor, all of the inputs go high. What am I doing wrong EDIT: The schematic is drawn wrong. For all of those variable resistors, the outputs actually come off of the wiper, not the other side. I couldn`t find out how to do this in the schematic program, so I drew it like such to show the general idea.

All the resistors in the image are variable and set-up to be such. Actually, I cant use the AD converter beacuse there will be two pads at least and each should have its own pressure sensor. The way I did it, the outputs from the sensors can either go into USB, or can go out to another pad, which sends it to USB, so I need just simple 1 or 0`s I think I tried putting the adjustor pot on the 5volt source, adjusting the voltage.

Didnt really like how it worked, but maybe Ill mess around with that again, thanks. 🔗 External reference